IAI America ERC3 User Manual

Page 265

Chapter 4 Operation

4.3

Operation in Pulse

Train Control Mode (How to Operate

Pulse

Train Control

Type)

255

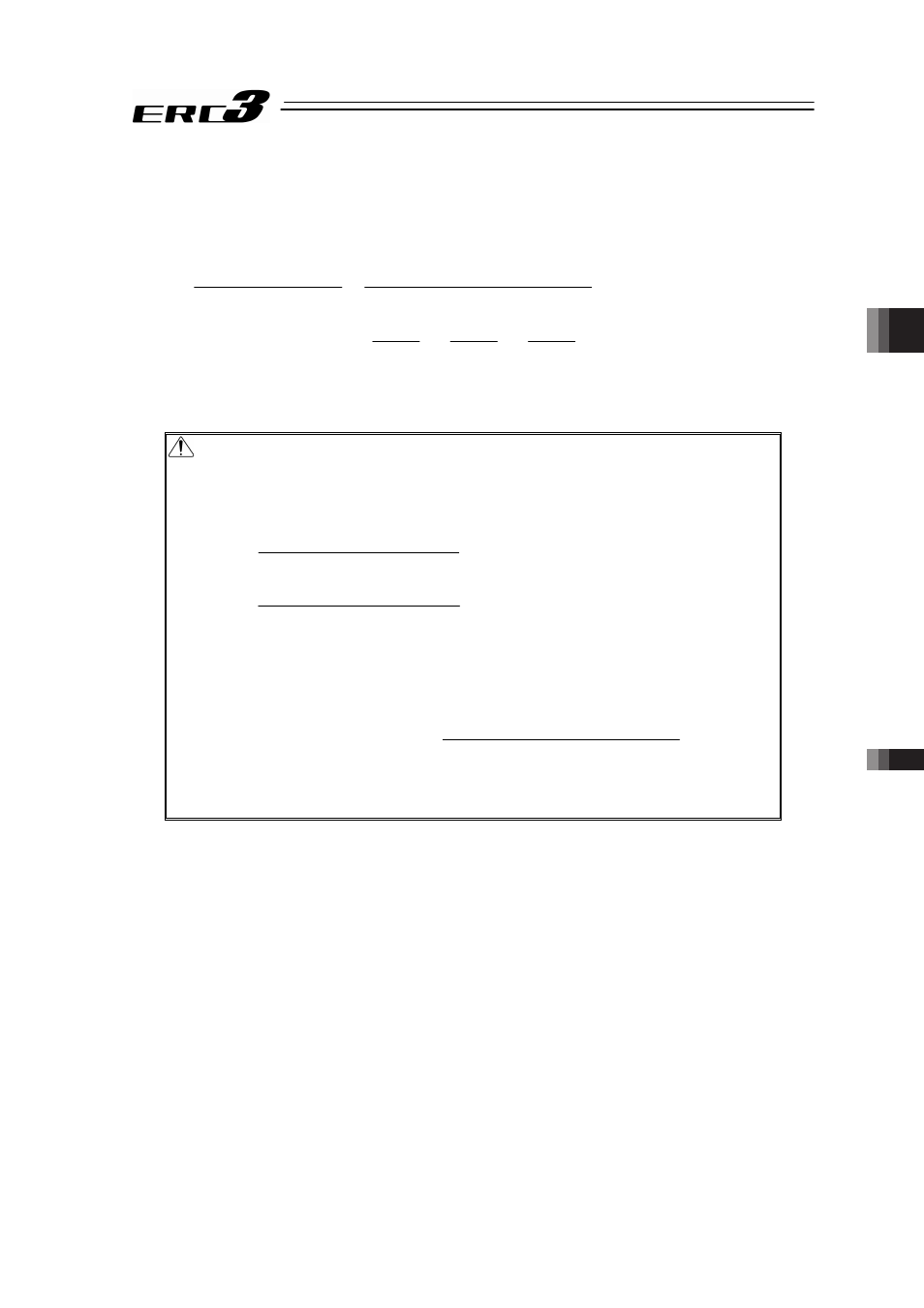

Examples of electronic gear calculations:

When operating ERC3 with 3mm lead length ball screw in 0.01 (1/100) mm of the movement

per unit

(Encoder pulse of ERC3 = 800pulse/rev)

The electronic gear numerator (CNUM) is calculated as 8, while the electronic gear

denominator (CDEN) is calculated as 3. Based on these settings, the travel distance per

command pulse train input pulse becomes 0.01mm.

Caution:

Ɣ The fraction has to be completely reduced so both the electric gear numerator

(CNUM) and electric gear denominator (CDEN) can be 4096 or less and make them

to be integral numbers. (Do not stop reducing the fraction on the way.)

Ɣ CNUM and CDEN on the line axis have to satisfy the following relative formulas.

Ɣ Do not set the minimum movement unit out of the encoder resolution ability. If this

setting is conducted, the actuator would not start moving until enough command

pulse is stored in the encoder resolution error.

Ɣ Pay attention not to exceed the specification limit when setting the velocity,

acceleration and deceleration.

=No. of Encoder Pluses [pulse/rev]

Ball Screw Lead Length [mm/rev]

u

Unit Travel Distance [deg/pulse]

=

800

3

u

1

100

=

8

3

Electronic Gear

Numerator (CNUM)

Electronic Gear

Denominator (CDEN)

2

31

t

Stroke Length [mm]

Ball Screw Lead Length [mm/rev]

u

No. of Encoder Pluses [pulse] u CNUM

2

31

t

Stroke Length [mm]

Ball Screw Lead Length [mm/rev]

u No. of Encoder Pluses [pulse] u CDEM

Encoder resolution [mm/pulse] =

Ball Screw Lead Length [mm/rev]

No. of Encoder Pluses [pulse/rev]