IAI America ERC3 User Manual

Page 346

Chapter 6

Adjustment of Operation

6.3 I/O Parameter

6.3.1 Positioner Mode 1, Positioner Mode 2 and Pulse

Train Control Mode

336

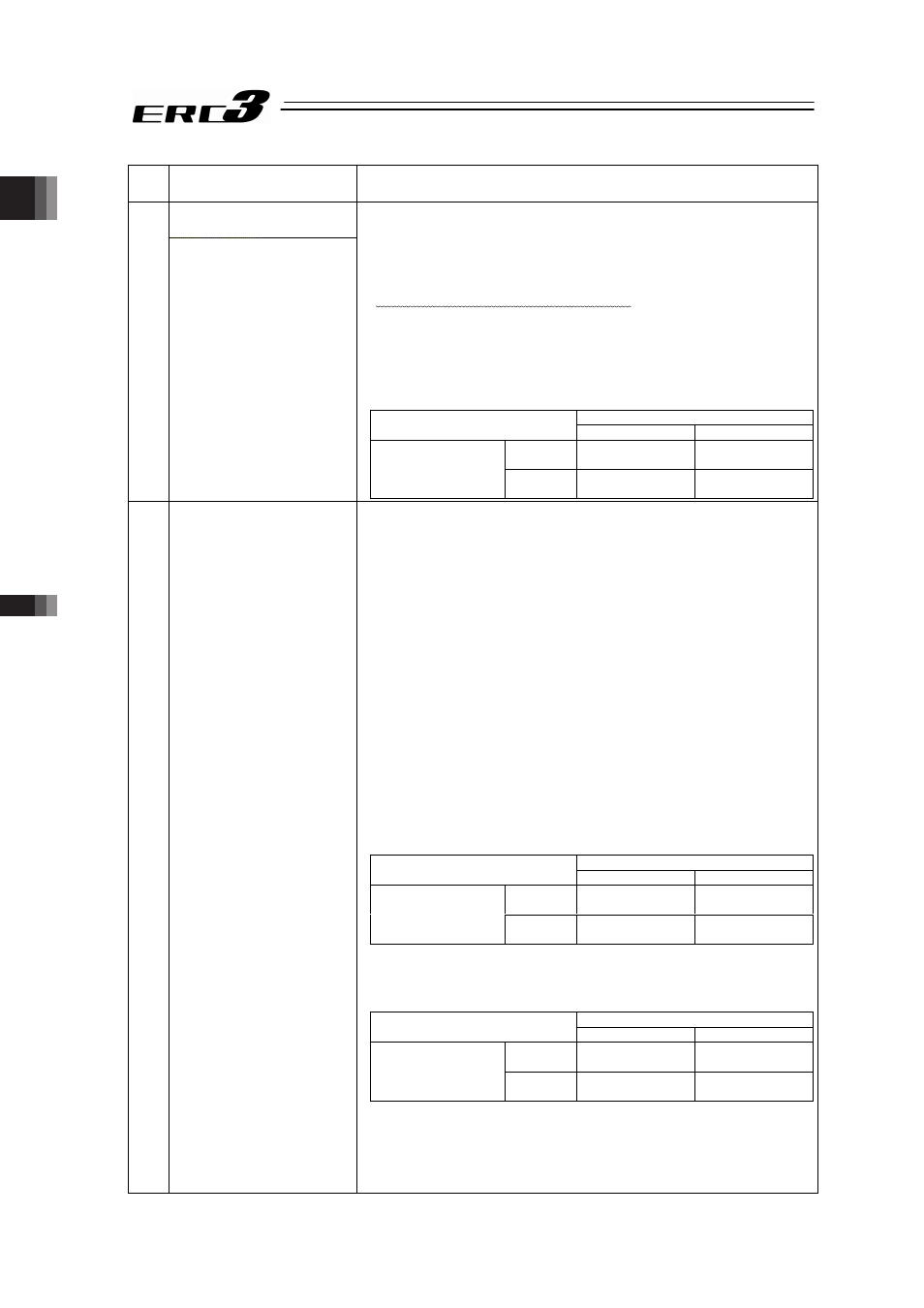

No.

Situation that requires

adjustment

How to Adjust

Speed is uneven during

the movement

3

Speed accuracy is not

appropriate

Ɣ Increase the value of “Velocity loop proportional gain”. By

setting a larger value, the follow-up ability to the speed

command becomes better.

Setting too large value makes the mechanical components easy

to vibrate. As a reference for the setting, increase the value little

by little by 20% from the initial setting.

For the velocity loop proportional gain parameter, the parameter

number differs depending on the setting of enable/disable of

Gain Scheduling and the high output setting.

Shown below is the table of velocity loop proportional gain

parameter numbers that are enable.

High Output Setting (Parameter No.152)

1 (Enable)

0 (Disable)

101 to

(Enable)

Parameter No.145 Parameter No.145

Gain Scheduling

(Parameter No.144)

to 101

(Disable)

Parameter No.153

Parameter No.31

4 Abnormal noise is

generated.

Especially, when stopped

state and operation in low

speed (less than

50mm/sec),

comparatively high noise

is generated.

Ɣ Input the Parameter No.33 “Torque Filter Time Constant”. Try to

increase by 50 as a reference for the setting. If the setting is too

large, it may cause a loss of control system stability and lead the

generation of vibration.

[Important] Prior to Adjustment:

This phenomenon is likely to occur when the stiffness of the

mechanical components is not sufficient. The actuator itself may

also resonate if its stroke is over 600mm or it is belt-driven type.

Before having an adjustment, check if:

1) Isn’t the setting in Parameter No.7 “Servo Gain Number”,

“Velocity Loop Proportional Gain” or “Velocity Loop Integrated

Gain” described below to extreme?

For the velocity loop proportional gain parameter and the

velocity loop integrated gain parameter, the parameter number

differs depending on the setting of enable/disable of Gain

Scheduling and the high output setting.

2) The stiffness of the load is sufficient as much as possible, or

the attachments are not loosened.

3) The actuator unit is mounted securely with a proper torque.

4) There is no waviness on the actuator mounting surface.

Shown below is the table of velocity loop proportional gain

parameter numbers that are enable.

High Output Setting (Parameter No.152)

1 (Enable)

0 (Disable)

101 to

(Enable)

Parameter No.145 Parameter No.145

Gain Scheduling

(Parameter No.144)

to 101

(Disable)

Parameter No.153

Parameter No.31

Shown below is the table of velocity loop integrated gain

parameter numbers that are enable.

High Output Setting (Parameter No.152)

1 (Enable)

0 (Disable)

101 to

(Enable)

Parameter No.146 Parameter No.146

Gain Scheduling

(Parameter No.144)

to 101

(Disable)

Parameter No.154

Parameter No.32