Position no.1 position no.2, 4) tension operation image diagram – IAI America ERC3 User Manual

Page 202

Chapter 4 Operation

4.2 Operation in Positioner Mode

4.2.2 Operation in Positioner Mode 1

192

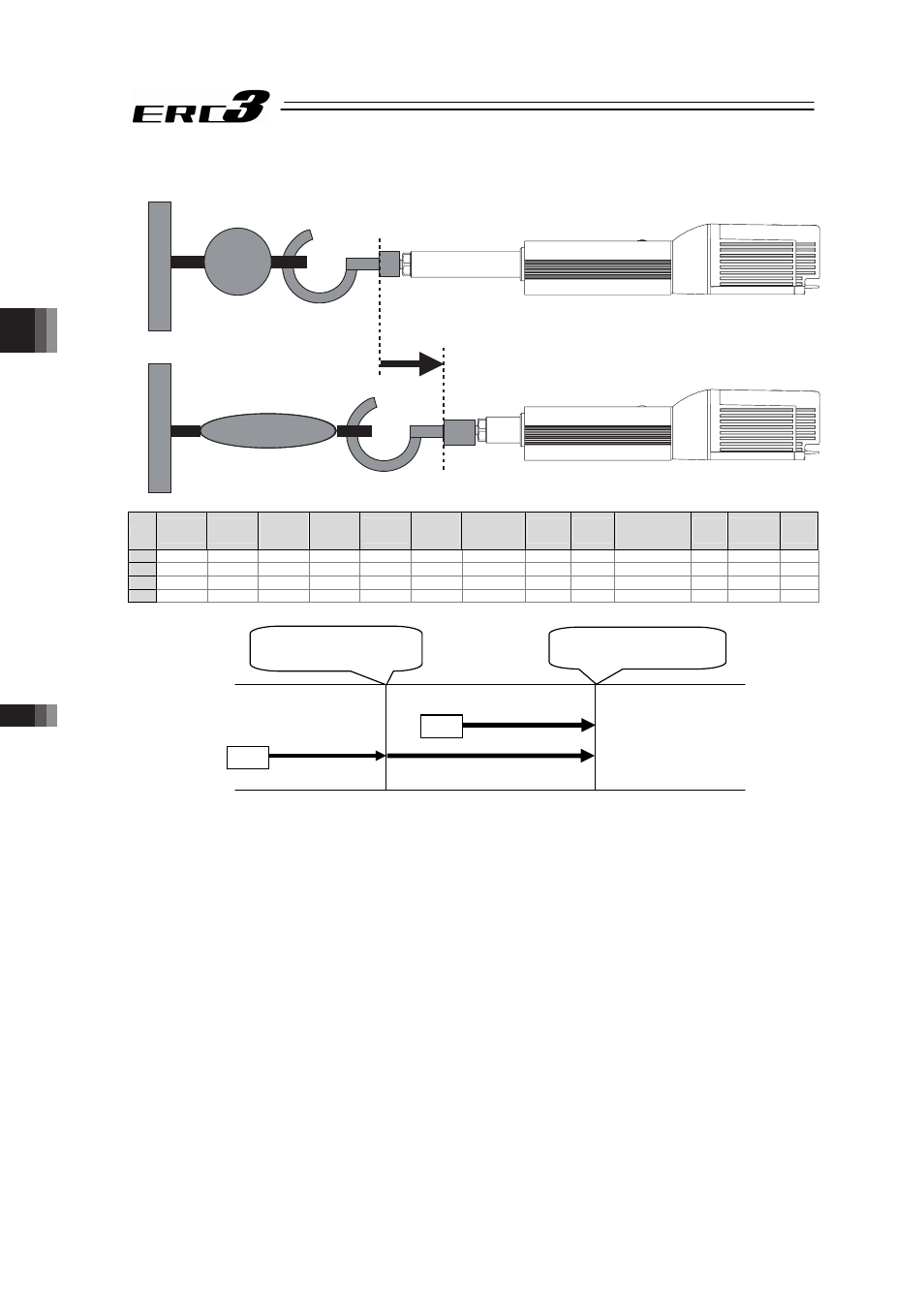

(4) Tension Operation

Image diagram

Position No.1

Position No.2

No.

Position

[mm]

Velocity

[mm/s]

Accele-

ration

[G]

Decele-

ration

[G]

Pressing

[%]

Thresh-

old

[%]

Positioning

width

[mm]

Zone+

[mm]

Zone-

[mm]

Acceleration/

Deceleration

mode

Incre-

mental

Transported

load

Stop

mode

0

1

100.00

250.00

0.20

0.20

0

0

0.10

0.00

0.00

0

0

0

0

2

80.00

250.00

0.20

0.20

50

0

–50.00

0.00

0.00

0

0

0

0

3

Control method

The control logic for the pulling operation is as same as the one for (3) Pressing Operation. The

control method is explained below by using the sample position table shown above.

1) Position No.2 indicates the settings of tension operation. The settings of “Position” and

“Positioning width” show the tension start position and the tension quantity, respectively.

Attach – (negative sign) to the tension quantity. Specify the upper limit of the torque

required for tension in percent (limited current value) in “Pressing”. The speed,

acceleration, and deceleration are the conditions of positioning to the coordinate value

(80mm) set in “Position”.

2) Position No.1 indicates the tension start preparation position. Specify a value larger than

the coordinate value at which the tension provided by position No.2 ends (80 – 50 = 30mm)

in “Position”.

3) First define the positioning in position No.1. Next, the operation in position No.2 moves the

actuator to the position of 80mm at the setting speed and rating torque and change to the

tension operation. The actuator moves by 50mm in the negative direction in the tension

operation. The upper limit of the tensile force is the torque set in percent.

4) Like the pressing operation, Current Position No. PE* is output when the axis stops by

pressing operation (pressing complete). Also, even when not stopping during a move in the

set range (pressing error), a movement is made for the setting of “Positioning width”, and

then turns ON.

ST*

ST*

ST*: Start position

Tension Operation

Approach Operation

Tension Operation

Tension start position

80mm

Temsion end position

80 – 50 = 30mm