2 mec mode 1, mec mode 2 and mec mode 3, 1] i/o parameter list – IAI America ERC3 User Manual

Page 348

Chapter 6

Adjustment of Operation

6.3 I/O Parameter

6.3.2 MEC Mode 1, MEC Mode 2 and MEC Mode 3

338

6.3.2 MEC Mode 1, MEC Mode 2 and MEC Mode 3

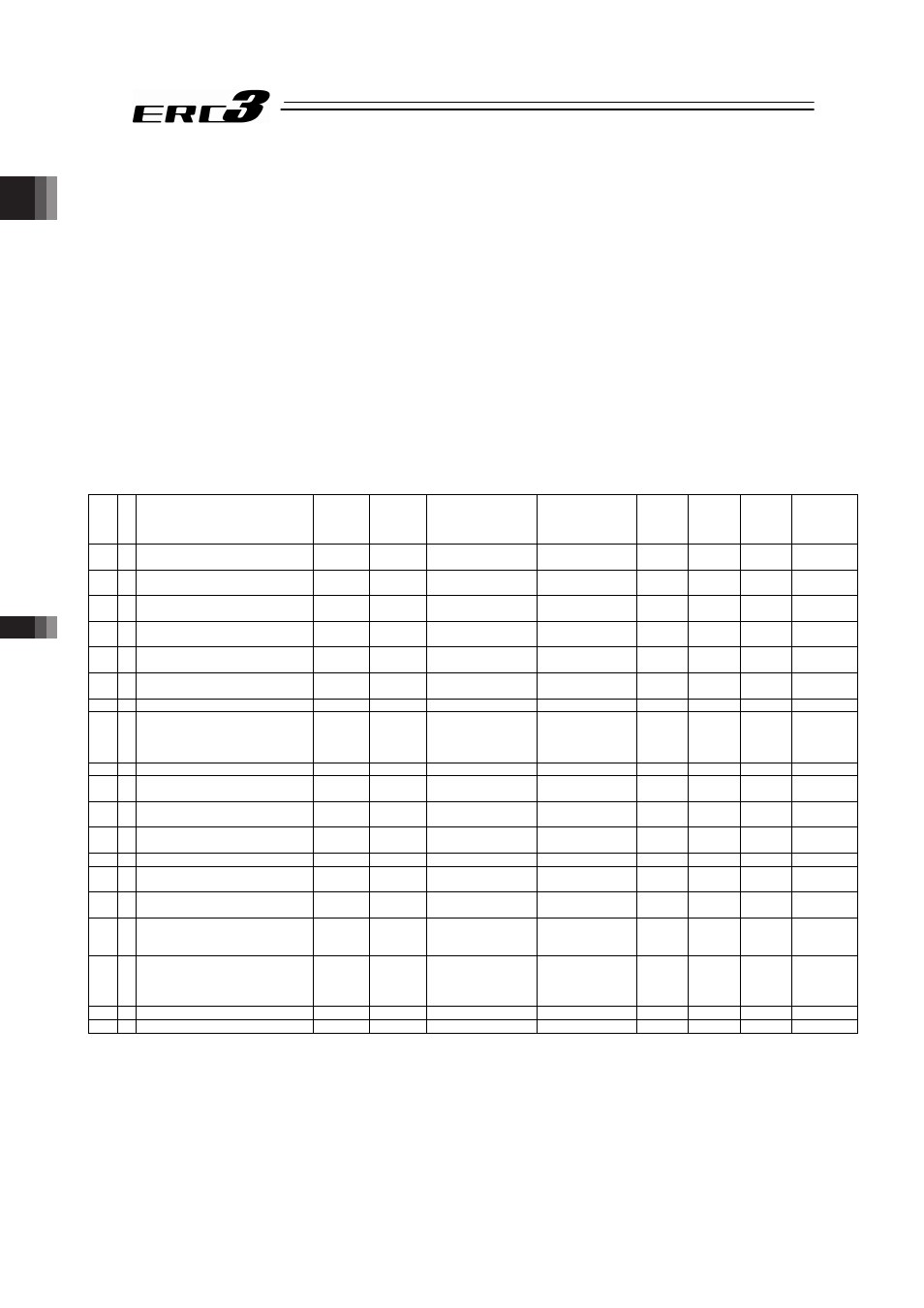

[1] I/O Parameter List

The categories in the table below indicate whether parameters should be set or not. There are

five categories as follows:

A : Check the settings before use.

B : Use parameters of this category depending on their uses.

C : Use parameters of this category with the settings at shipments leaving unchanged as a

rule. Normally they may not be set.

D : Parameters of the category are set at shipment in accordance with the specification of the

actuator. Normally they may not be set.

E : Parameters of the category are exclusively used by us for convenience of production.

Changing their settings may not only cause the actuator to operate improperly but also to

be damaged. So, never change the setting of the parameters.

Category do not appear on the teaching tool.

Also, the unused parameter numbers are not mentioned in the list.

[MEC Mode 1, MEC Mode 2 and MEC Mode 3]

No.

C

at

eg

or

y

Name

Symbol

Unit

Input Range

Default factory

setting

For Mec

Mode 1

For Mec

Mode 2

For Mec

Mode 2

Relevant

sections

This section

1 B Positioning width

INP

mm

0.01 to Actuator

eigenvalue

In accordance with

actuator

(Note1)

{

[2] (1)

3 C Servo gain No.

PLG0

–

0 to 31

In accordance with

actuator

(Note1)

{

{

{

[2] (2)

[3]

4 C Torque filter time constant

TRQF

–

0 to 2500

In accordance with

actuator

(Note1)

{

{

{

[2] (3)

[3]

5 C Velocity loop proportional gain

VLPG

–

1 to 27661

In accordance with

actuator

(Note1)

{

{

{

[2] (4)

[3]

6 C Velocity loop integral gain

VLPT

–

1 to 217270

In accordance with

actuator

(Note1)

{

{

{

[2] (5)

[3]

7 C Press velocity

PSHV

mm/s 1 to actuator's max.

pressing speed

In accordance with

actuator

(Note1)

{

{

[2] (6)

8 C Press & hold stop judgment period

PSWT

msec

0 to 9999

255

{

{

[2] (7)

9 B Current limitation in pressing and

bridging

PSFC

–

0: Current limitation

value while moving

1: Push-motion

current-limiting value

0

{

{

[2] (8)

10 B Auto servo motor OFF delay time

ASO1

sec

1 to 9999

1

{

{

{

[2] (9)

11 B Stop mode selection

SMOD

–

0: Full stop

1: Servo-motor stop

0

{

{

{

[2] (10)

12 B Current-limiting value at standstill

during positioning

SPOW

%

1 to 70

35

{

{

{

[2] (11)

13 C Current-limiting value during home

return

ODPW

%

1 to 100

In accordance with

actuator

(Note1)

{

{

{

[2] (12)

15 C Soft limit

LIMM

mm

0.01 to 9999.99

Actual stroke

(Note1)

{

{

{

[2] (13)

16 C Home return offset level

OFST

mm

0.00 to 9999.99

In accordance with

actuator

(Note1)

{

{

{

[2] (14)

17 D Home return direction

ORG

–

0: Reverse

1: Forward

In accordance with

actuator

(Note1)

{

{

{

[2] (15)

18 B Simple absolute unit

ETYP

–

0: Incremental

1: Simple absolute

type 1

In accordance with

specification at

order accepted

{

[2] (16)

19 A

Absolute battery retention time

[0:20 days/1:15 days /2:10 days/3:5

days]

AIP

days

0: 20 days

1: 5 days

2: 10 days

3: 5 days

2

{

[2] (17)

20 B Position data change password

PASS

–

0000 to 9999

0000

{

{

[2] (18)

25 B PIO inch distance

IOID

mm

0.01 to 1.00

0.1

{

{

{

[2] (19)

Note 1 The setting values vary in accordance with the specification of the actuator. At shipment, the

parameters are set in accordance with the specification.

Note 2 This setting cannot be made for Quick Teach. This shows the effective parameters during an

operation.