Pulse train control mode – IAI America ERC3 User Manual

Page 35

25

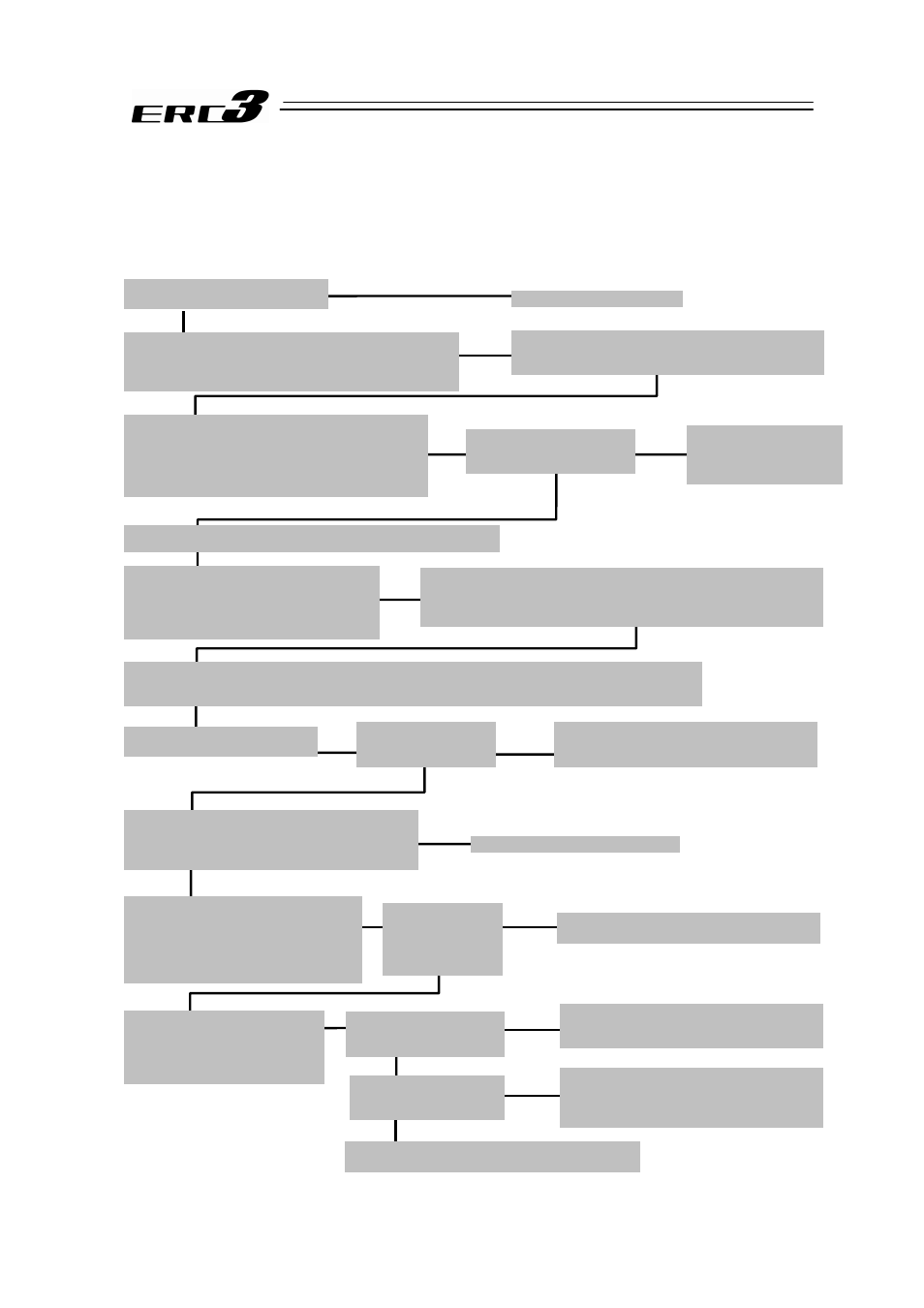

2. Pulse Train Control Mode

This product allows positioning control by the pulse train.

It is necessary to have the positioning control function able to output the pulse train on the host

controller (PLC).

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by

referring to the procedure below. “PC” stated in this section means “RC PC software”.

Set the Electronic Gear [Refer to Section

4.3 [8] (1)]

Set the electronic gear ratio based on the

amount of actuator operation per pulse in

Parameters No.65 and 66.

ψ

Check Item

Is the minimum unit of operation set to the value bigger than the

minimum resolution of the encoder?

Is the fraction of the electronic gear ratio reduced to its lowest terms?

φ

Yes

Pulse Train Input Output Mode Setting [Refer to Section 4.3 [8] (2)]

Set the command pulse train input status for the parameter No.63 and No.64.

Set Teach Mode to Monitor Mode 2 and disconnect the teaching tool after the setting is complete.

Servo ON

Input servo ON signal from PLC.

ψ

Check Item

Does the status LED

[SV] on the panel?

No ψ

Confirm the content of alarm on the teaching

tool such as PC to have an appropriate

treatment.

φ

Yes

Safety Circuit Check

Check that the emergency stop circuit (or motor

drive-power cutoff circuit) operates normally to turn

OFF the servo.

No ψ

Check the emergency stop circuit.

ω

Yes

ψ

No ψ

Contact us or our distributor.

ω

Yes

No ψ

ψ

Check Item

Is the red light [ALM] on the

LED status display OFF?

Connect the teaching tool

such as PC to confirm the

content of alarm and have

an appropriate treatment.

Test Run Adjustment 2

[Operation Mode AUTO]

Output the pulse train from PLC to

the controller and check the

system operation.

ψ

No ψ

No ψ

Check the electronic gear ratio setting.

Confirm the command pulse train input mode

setting.

Confirm that there is no problem in the

actuator installation, the actuator operation

condition demands a voltage more than rated

voltage, and appropriate pulse trains are input.

Power Supply and Alarm Check

Connect a teaching tool such as PC, turn the power

ON for unit.

Select [Teaching Mode 1 Safety Speed Activated /

PIO Operation Invalid] in the teaching tool such as

PC.

ω

Yes

φ

Yes

Check of Packed Items

Are there all the delivered items?

Installation and Wiring [Refer to Chapter 2 and Chapter

3]

Perform the installation of and wiring for the actuator and

controller.

Point Check Item [Refer to Section 2.3.4]

• Is frame ground (FG) connected?

• Has the noise countermeasure been taken?

ψ

Test Run Adjustment 1

[Operation Mode MANU]

Check with a teaching tool such as the

PC with no work being loaded, and check

the operation range with JOG operation

with the work being loaded.

Check if there is any problem in the way of

actuator mount.

Check Item

Is there any risk of

interfering with

peripheral

equipment?

No ψ

ω

Yes

Can the positioning

operation be performed

normally?

ω

Yes

ω

Yes

Is it in condition without

any vibration and

abnormal noise?

Test Run Adjustment 3

Check the system operation conducted by PLC.

PIO Pattern Settings

Set 0 or 1 to Parameter No.25 (Pulse Train Control Mode).