Chapter 8 actuator maintenance check, 1 inspection items and schedule, 2 external visual inspection – IAI America ERC3 User Manual

Page 385: 3 cleaning

Chapter 8

Actuator Maintenance Check

8.1 Inspection Items and Schedule

8.2 External V

isual Inspection, 8.3 Cleaning

375

Chapter 8 Actuator Maintenance Check

8.1 Inspection Items and Schedule

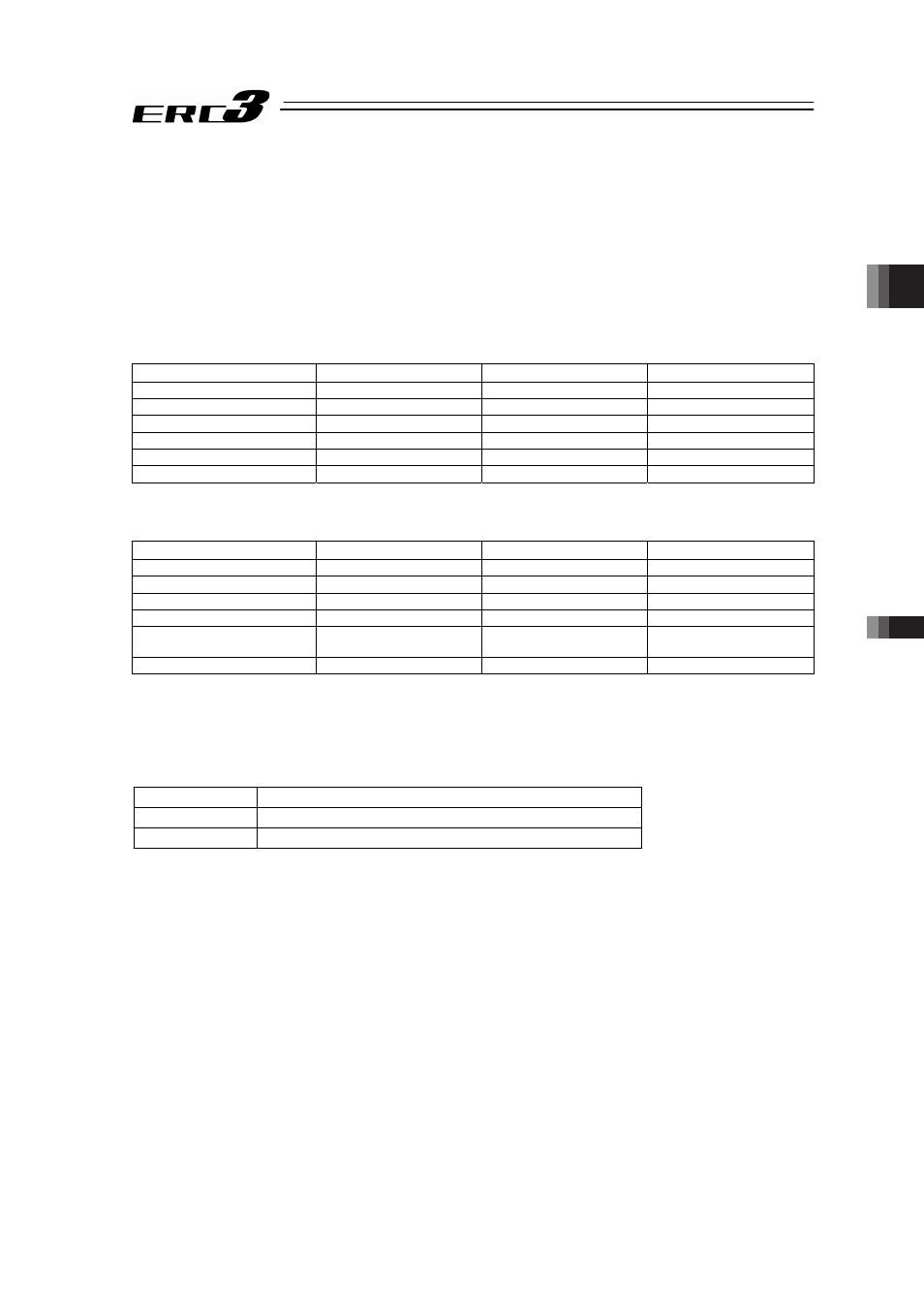

Follow the maintenance inspection schedule below.

It is assumed that the equipment is operating 8 hours per day.

If the equipment is running continuously night and day or otherwise running at a high operating rate,

inspect more often as needed.

[Slider Type]

External visual inspection

Internal inspection

Greasing

Start of work inspection

{

1-month inspection

{

6-month inspection

{

{

12-month inspection

{

{

{

Every 6 months thereafter

{

Every 12 months thereafter

{

{

{

[Rod Type]

External visual inspection

Internal inspection

Greasing

Start of work inspection

{

1-month inspection

{

3-month inspection

{

{

(Rod sliding surface)

Every 3 months since

{

{

(Rod sliding surface)

6-month inspection or every

5000km of operated distance

{

{

{

(Ball Screw/Guide )

Every 1 year thereafter

{

{

{

(Ball Screw/Guide)

8.2 External Visual Inspection

An external visual inspection should check the following things.

Main unit

Loose actuator mounting bolts, other loose items

Cables

Scratches, proper connections

Overall

Irregular noise, vibration

If the actuator is installed in the vertical orientation, the grease applied on the guide may drop in

some environmental conditions. Clean and supply the grease when it is necessary.

8.3 Cleaning

• Clean exterior surfaces as necessary.

• Use a soft cloth to wipe away dirt and buildup.

• Do not blow too hard with compressed air as it may cause dust to get in through the gaps.

• Do not use oil-based solvents as they can harm lacquered and painted surfaces.

• To remove severe buildup, wipe gently with a soft cloth soaked in a neutral detergent or alcohol.