2] detail explanation of parameters, 2) servo gain number (parameter no.3), 3) torque filter time constant (parameter no.4) – IAI America ERC3 User Manual

Page 350

Chapter 6

Adjustment of Operation

6.3 I/O Parameter

6.3.2 MEC Mode 1, MEC Mode 2 and MEC Mode 3

340

[2] Detail Explanation of Parameters

(1) Default positioning width (in-position) (Parameter No.1)

No.

Name

Symbol

Unit

Input Range

Default factory setting

1

Default positioning width

INP

mm

0.01

(Note 1)

to 999.99

0.10

The positioning complete signal PEND/INP is output once the remaining movement amount

comes into this width.

Note 1 It is down to the minimum positioning width (L = Lead length/800).

(2) Servo gain number (Parameter No.3)

No.

Name

Symbol

Unit

Input Range

Default factory setting

3

Servo gain number

PLGO

–

0 to 31

In accordance with

actuator

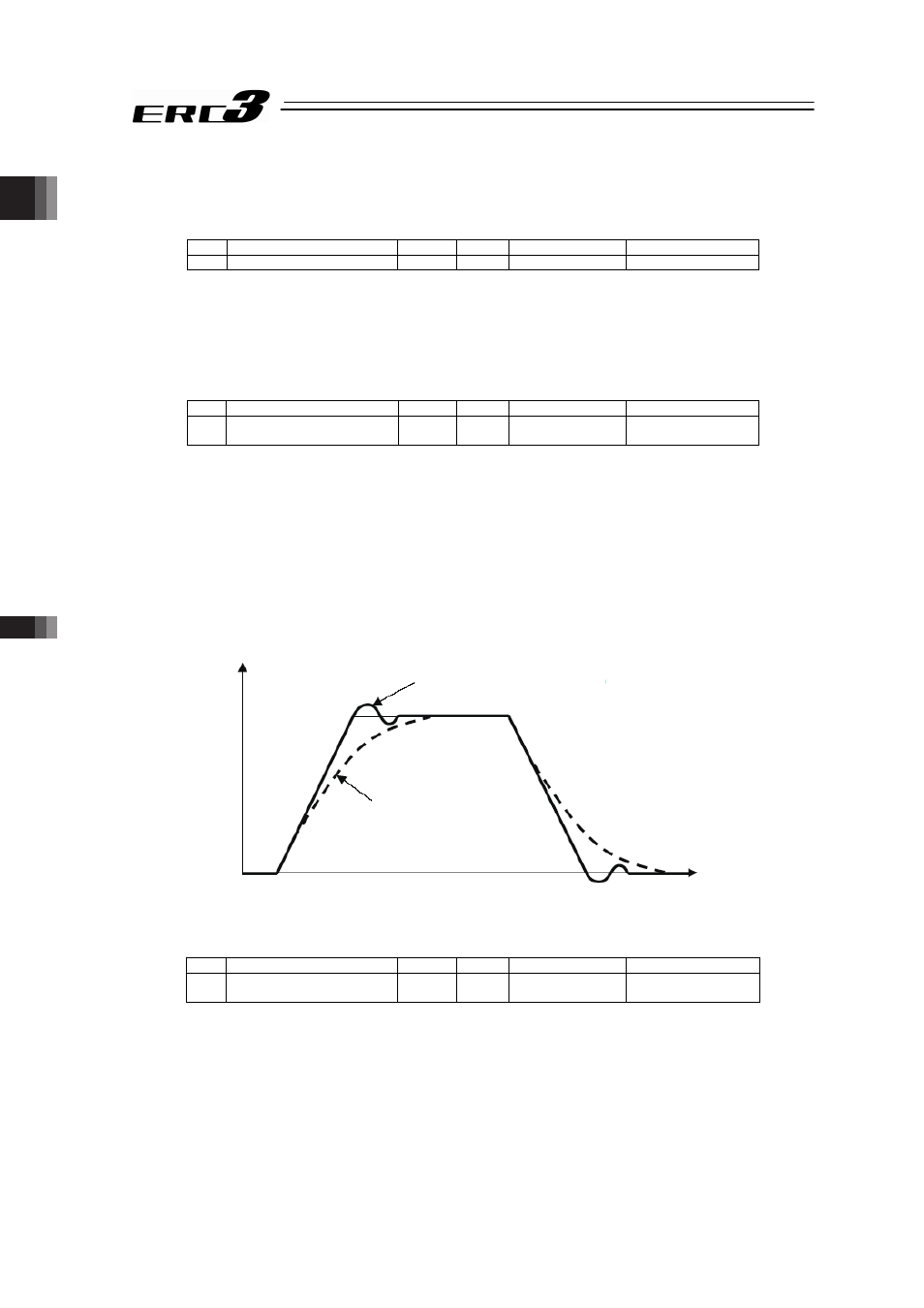

The servo gain is also called position loop gain or position control system proportion gain. The

parameter defines the response when a position control loop is used. Increasing the set value

improves the tracking performance with respect to the position command. However, increasing

the parameter value excessively increases the chances of overshooting.

When the set value is too low, the follow-up ability to the position command is degraded and it

takes longer time to complete the positioning.

For a system of low mechanical rigidity or low natural frequency (every object has its own

natural frequency), setting a large servo gain number may generate mechanical resonance,

which then cause not only vibrations and/or noises but also overload error to occur.

When the set value is high (over-shoot)

When the set value is low

Velocity

Time

(3) Torque filter time constant (Parameter No.4)

No.

Name

Symbol

Unit

Input Range

Default factory setting

4

Torque filter time constant

TRQF

–

0 to 2500

In accordance with

actuator

This parameter decides the filter time constant for the torque command. When vibrations and/or

noises occur due to mechanical resonance during operation, this parameter may be able to

suppress the mechanical resonance. This function is effective for torsion resonance of ball

screws (several hundreds Hz).