3) pressing operation sample use, Positioning by setting of coordinate value, Stop of pressing – IAI America ERC3 User Manual

Page 199

Chapter 4 Operation

4.2 Operation in Positioner Mode

4.2.2 Operation in Positioner Mode 1

189

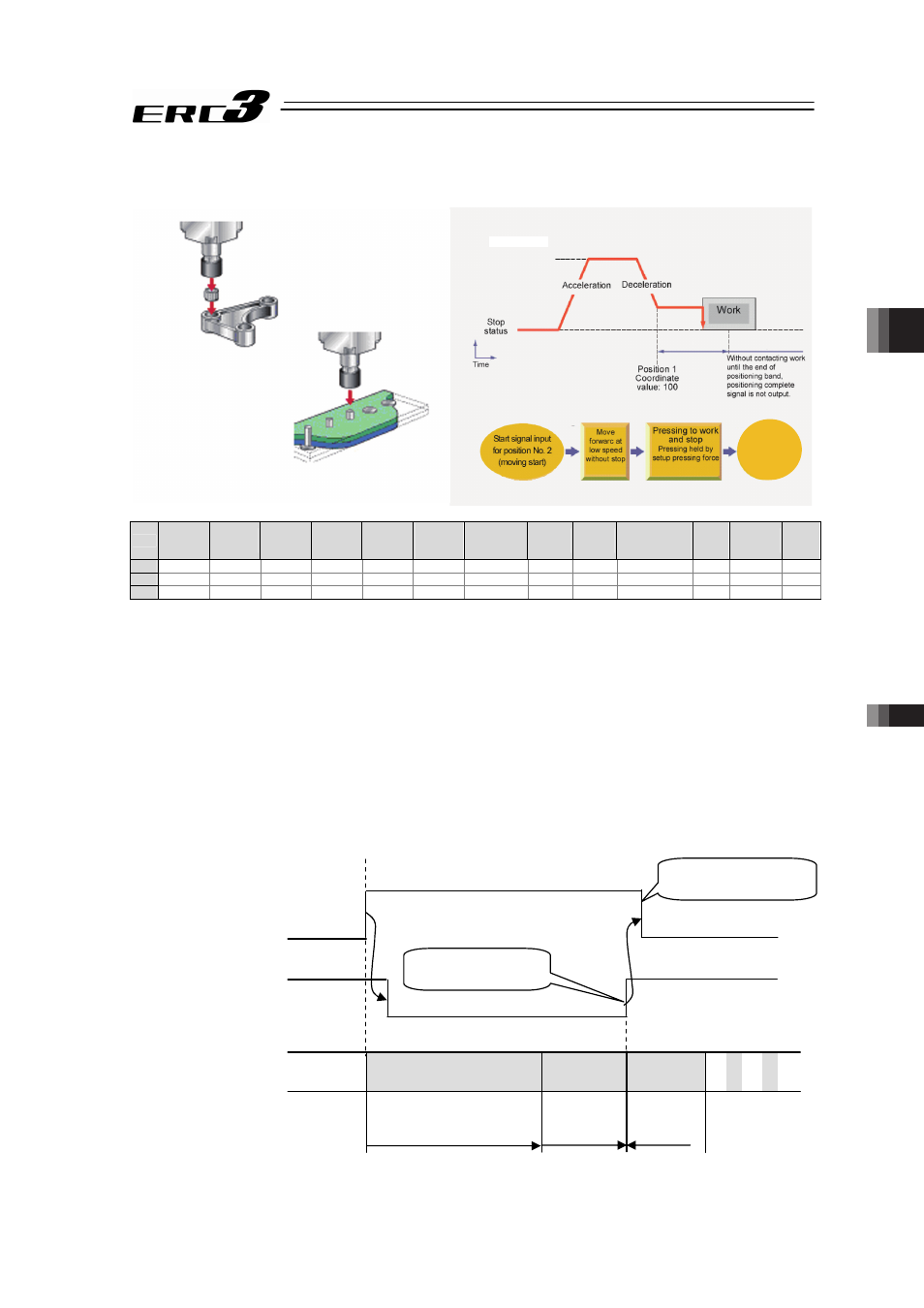

(3) Pressing operation

Sample use

No.

Position

[mm]

Velocity

[mm/s]

Accele-

ration

[G]

Decele-

ration

[G]

Pressing

[%]

Thresh-

old

[%]

Positioning

width

[mm]

Zone+

[mm]

Zone-

[mm]

Acceleration/

Deceleration

mode

Incre-

mental

Transported

load

Stop

mode

0

1

0.00

250.00

0.20

0.20

0

0

0.10

0.00

0.00

0

0

0

0

2

100.00

250.00

0.20

0.20

50

0

50.00

0.00

0.00

0

0

0

0

(Position No.2 sets pressing operation.)

Control method

1) The method of controlling the pressing operation is the same as that described in (1)

Positioning except the setting of the position table. Any setting of “Pressing” in the position

table allows the pressing operation to be done. “Positioning width” is assumed as pressing

operation distance.

2) The actuator moves at the setting speed and rating torque to the position of the coordinate

set in “Position” in the similar way as normal positioning. The operation is executed with the

value set in “Positioning width” for the amount of movement in the pressing operation, and

the torque (current limit) set in % in “Pressing” for the pressing operation as the upper limit.

Ԛ

Current Position No. PE* is output when the axis stops by pressing operation (pressing

complete). Also, even when not pressing a work piece (pressing error), a movement is

made for the setting of “positioning width”, and then turns ON.

Turned OFF by

turning PE* ON.

Turned ON even

in miss-pressing

Start signal

ST*

(PLCĺController)

Current position No.

PE*

(ControllerĺPLC)

Operation of actuator

Approach operation

Pressing

operation

Pressing

completion

Positioning by setting of

coordinate Value

Movement by

positioning

width

Stop of

pressing

Positioning

Completion

1)

2)

3)

4)

1)

3) 4)

2)

Positioning width 50

Velocity

Press-fitting process

Caulking process

250mm/sec