Chapter 4 operation, 1 basic operation, 1 basic operation methods – IAI America ERC3 User Manual

Page 163: 1] positioner mode 1 (pio operation of erc3), Completion signal, Teaching tool erc3

Chapter 4 Operation

4.1 Basic Operation

153

Chapter 4 Operation

4.1 Basic Operation

ERC3 has 6 types of operation method when combined with peripheral devices. In addition,

each operation method has several operation patterns to meet various ways of use.

Please note, though, that these patterns are to be determined by selecting the model code

when in order, thus have an operation with a control logic that corresponds to the model code.

[Refer to Guideline for Control Method]

4.1.1 Basic Operation Methods

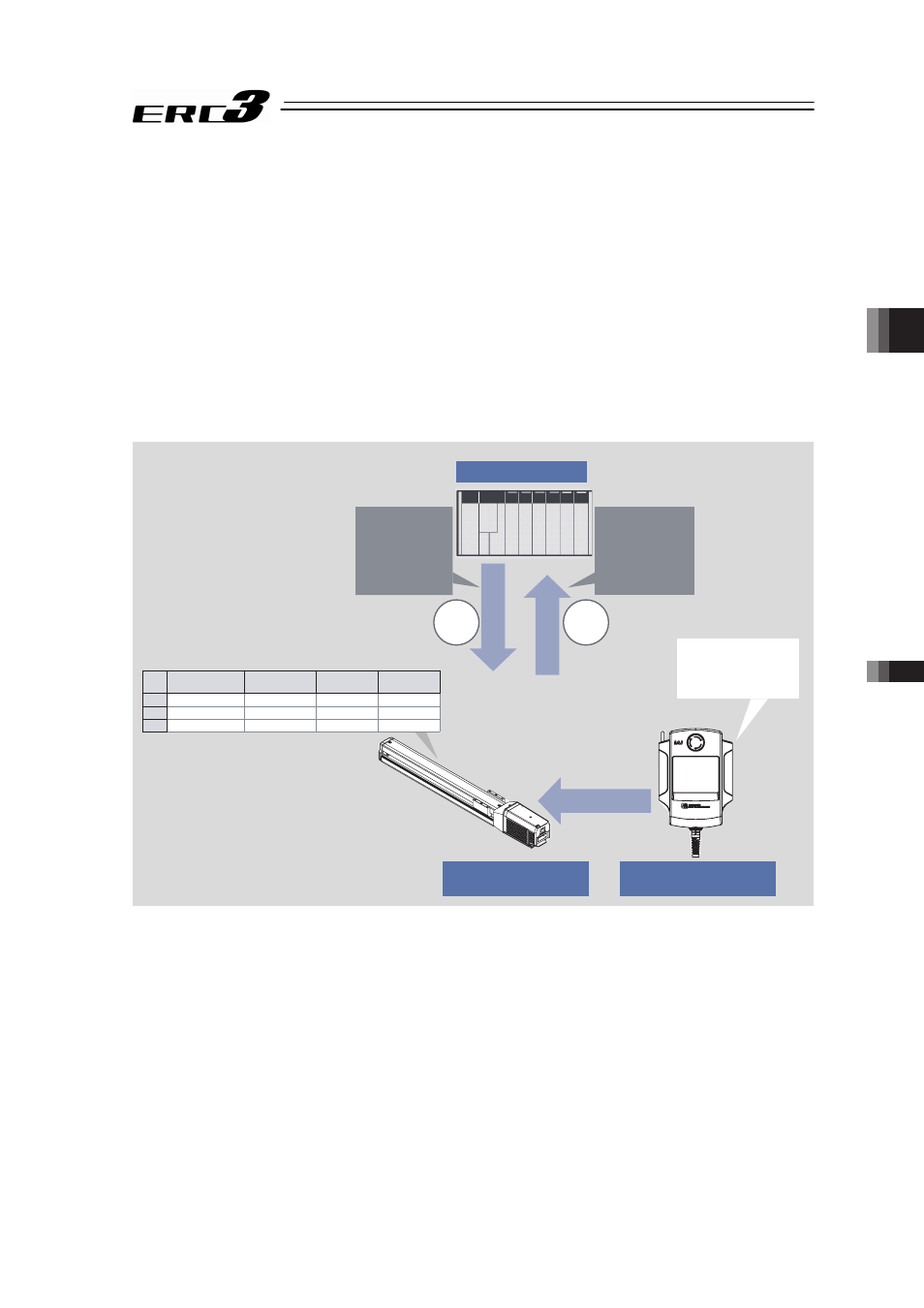

[1] Positioner Mode 1 (PIO Operation of ERC3)

Three types of operation patterns and 16 points of positioning at the maximum are available.

Completion

Signal

Signal

Signal

Edit Position

Table of

controller

Position Number

+

Start Signal

PLC

Enter a data including

position, velocity,

acceleration or

deceleration, etc.

Teaching Tool

ERC3

No.

[G]

0

1

100.00

0.30

0.30

2

200.00

0.30

0.30

100.00

200.00

Acceleration Deceleration

Velocity

[mm]

[mm/s]

[G]

Position

1) Set target positions (coordinate values), velocities, accelerations, and decelerations by the

required number of positioning points in the position table by using a teaching tool such as

PC software.

2) Enter the binary data of position numbers subject to positioning on the PLC and turn ON

the start signal.

3) The actuator is placed at the proper coordinate value according to the positioning

information in the specified position number.

4) After the positioning is completed, the completion signal is output.

The above procedure describes the basic operation method in the positioner mode 1.