IAI America ERC3 User Manual

Page 244

Chapter 4 Operation

4.2 Operation in Positioner Mode

4.2.3 Operation in Positioner Mode 2 (Operation Using PIO Converter)

234

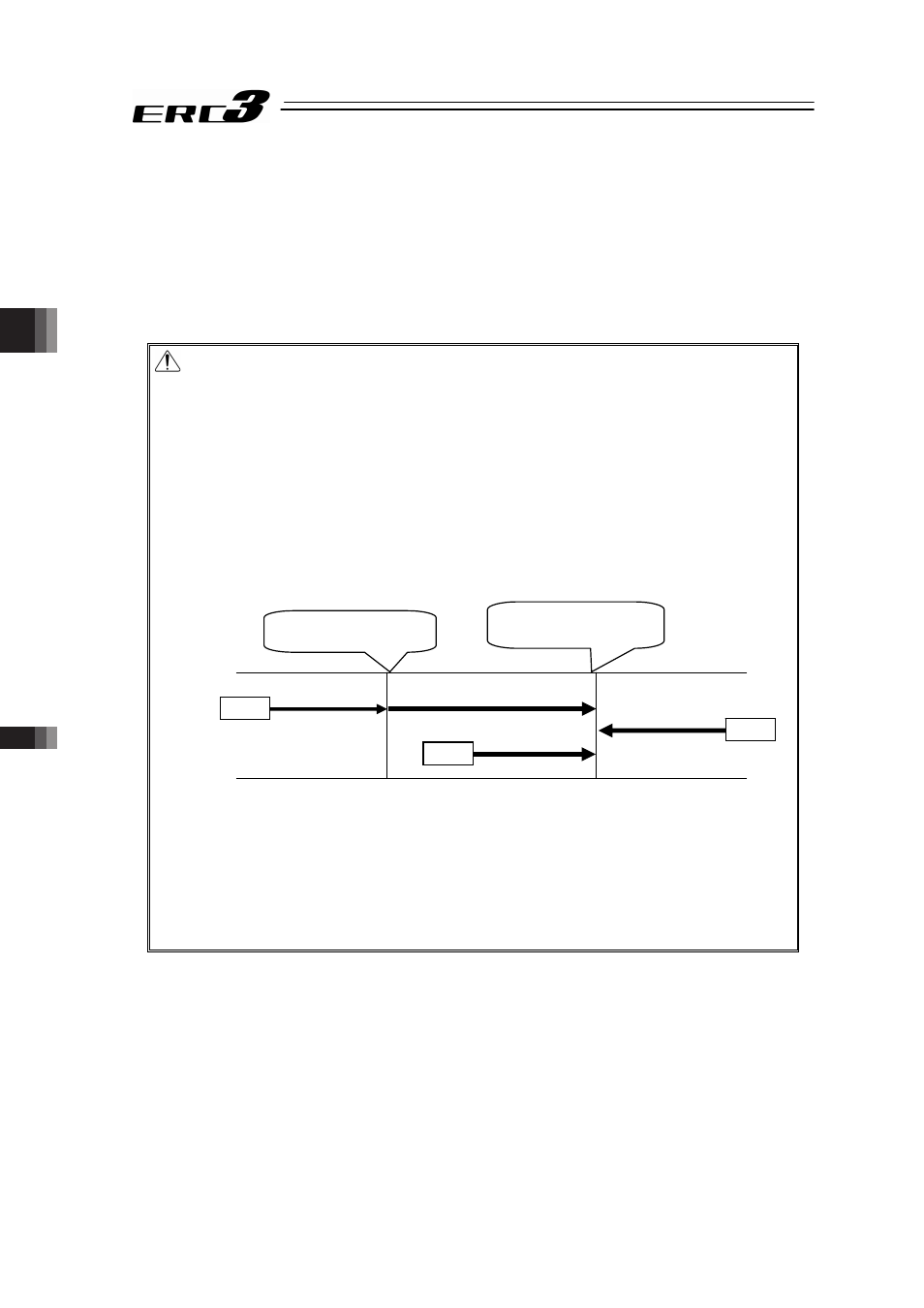

3) First define the positioning in position No.1. Next, the operation in position No.2 moves the

actuator to the position of 80mm at the setting speed and rating torque and change to the

tension operation. The actuator moves by 50mm in the negative direction in the tension

operation. The upper limit of the tensile force is the torque set in percent.

4) In the similar way as pressing, the positioning complete signal is output when the shaft is

stopped by tension (pressing complete). If the actuator cannot be stopped during

movement within the setting positioning width (miss-pressing), it moves by the setting

distance to stop but PEND is not turned ON. The current position No. PE* is turned ON at

the completion of pressing and even in miss-pressing.

Caution: (1) The speed during tension operation is set in Parameter No.34. The

pressing operation speed is 20mm/s.

Do not set any value larger than the value in the list. If the speed setting in

the position table is below this set value, pressing is performed with the set

speed.

(2) The tension ready position should be the tension start position or forward. If

not, the moving direction varies depending on the start position to be

dangerous.

The tension operation from a coordinate (less than 30mm = 80 – 50 in the

above example) located before the end position (30mm) changes to the

pressing operation from the current position to the tension end position.

Note that the tension operation after positioning to the position of 80mm

does not take place.

(3) The work is pulled also after completion of the tension. The work is drawn

back or pulled further if the work is moved. When the work is drawn back

before the approach position, alarm code 0DC “pressing operation range

over error” occurs to stop the work. When the work is moved in the tension

direction and the load current becomes less than the current limit value

(pressing in percent), PEND is turned OFF. The work reaches the tension

moving distance set in “Positioning width” to cause miss-pressing.

Pressing Operation

ST*: Start position

ST*

ST*

ST*

Tension Operation

Approach Operation

Tension Operation

Tension start position

80mm

Temsion end position

80 – 50 = 30mm