Transference of pio signal between controllers, Plc timer setting – IAI America ERC3 User Manual

Page 22

12

19. Transference of PIO Signal between Controllers

Please note the following when conducting transference of PIO signal between controllers.

To certainly transfer the signal between controllers with different scan time, it is necessary to

have longer scan time than the one longer than the other controller. To ensure to end the

process safely, it is recommended to have the timer setting more than twice as long as the

longer scan time at least.

䎃

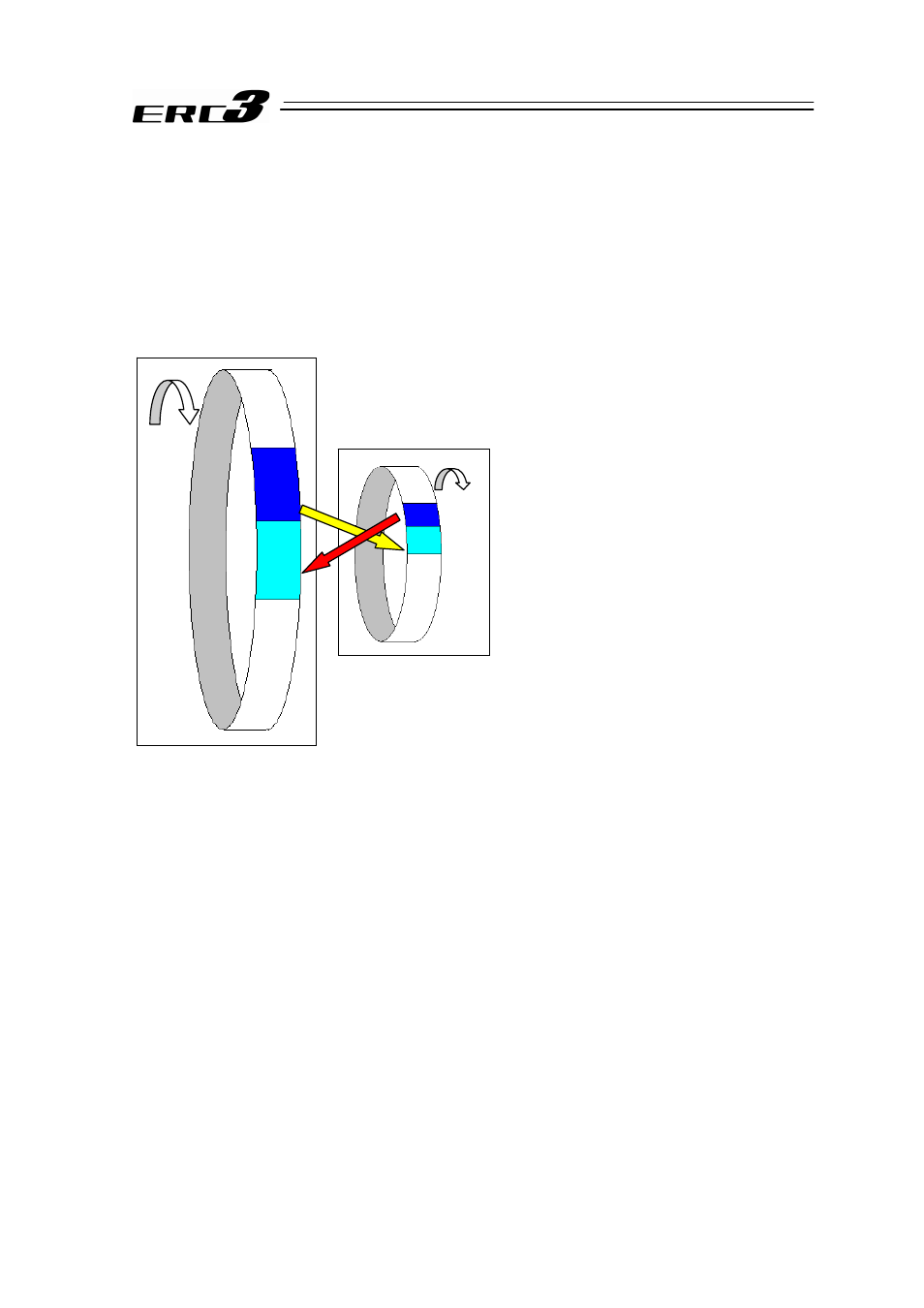

Ɣ Operation Image

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

䎃

Also, if one tries to read the signal that is being re-written by the other, the signal may be read wrongly.

Make sure to read the signal after the rewriting is complete. (It is recommended to have more than 2 scan

periods to wait.) Make sure not to have the output side to change the output until the other side completes

the reading. Also, a setting is made on the input area not to receive the signal less than a certain time to

prevent a wrong reading of noise. This duration also needs to be considered.

20. PLC Timer Setting

Do not have the PLC timer setting to be done with the minimum setting.

Setting to “1” for 100msec timer turns ON at the timing from 0 to 100msec while 10msec timer

from 0 to 10msec for some PLC.

Therefore, the same process as when the timer is not set is held and may cause a failure such

as the actuator cannot get positioned to the indicated position number in Positioner Mode.

Set “2” as the minimum value for the setting of 10msec timer and when setting to 100msec, use

10msec timer and set to “10”.

This controller

(scan time 1msec)

PLC

(e.g. scan time is 20msec)

Output

Process

Input

Process

As shown in the diagram, the input and output

timings of two devices that have different scan

time do not match, of course, when transferring

a signal.

There is no guarantee that PLC would read the

signal as soon as this controller signal turns on.

In such a case, make the setting to read the

signal after a certain time that is longer than the

longer scan time to ensure the reading process

to succeed on the PLC side.

It is the same in the case this controller side

reads the signal.

In such a case, it is recommended to ensure 2

to 4 times of the scan time for the timer setting

margin.

It is risky to have the setting below the scan

time since the timer is also processed in the

scan process.

In the diagram, PLC can only read the input

once in 20msec even though this controller

output once in 1msec.

Because PLC only conducts output process

once in 20msec, this controller identifies the

same output status for that while.