IAI America ERC3 User Manual

Page 189

Chapter 4 Operation

4.2 Operation in Positioner Mode

4.2.2 Operation in Positioner Mode 1

179

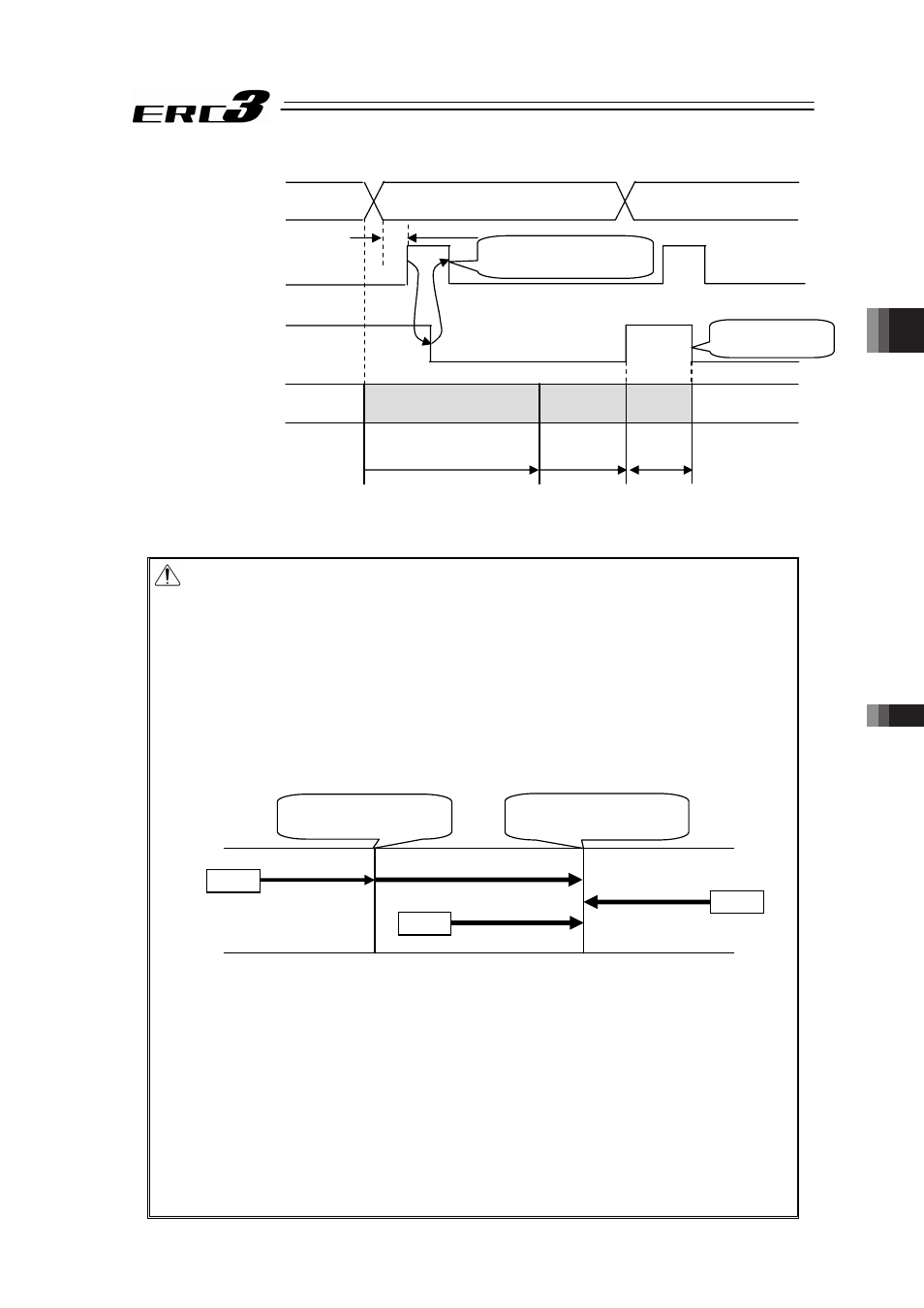

(Note 1) Set the period taken from entering the position number to turning CSTR ON to 6ms or

longer. Because 6ms timer process on the PLC is also entered to the controller,

positioning at another position may occur. Take the PLC scan time into account.

Caution: (1) The speed during pressing operation is set in Parameter No.34. The

pressing operation speed is 20mm/s. Do not set any value larger than the

value in the list.

If the speed setting in the position table is below this set value, pressing is

performed with the set speed.

(2) The approach start position of pressing should be located at or before the

pressing start position (coordinate 100mm or less in the above example) If

not, the moving direction varies depending on the start position to be

dangerous.

For example, pressing at coordinate larger than the pressing end position

(larger than 150mm) is performed in the direction from the current position

to the pressing end position. Note that pressing after positioning to the

position of coordinate 100mm does not take place.

(3) The work is pressed after the pressing is completed. The work may move

backward or forward. If the actuator is moved backward before the

approach position, alarm code 0DC “Pressing operation range over error”

occurs to stop the actuator. In movement of the work in the pressing

direction, PEND is turned OFF if the load current becomes lower than the

current limit (pressing [%]). Miss-pressing occurs when the actuator moves

by the pressing moving distance set in “Positioning width”.

(4) Do not make control of changing to pressing on the way of normal

positioning (before PEND turning ON). Depending on the position at which

start signal CSTR is turned ON, the pressing is performed improperly. Then

the PLC cannot manage the position of the actuator.

(5) If the actuator gets pressed to the work during the approach operation, 0DC

“Pressing operation range over error” would be issued.

T1t6ms

(Note 1)

Turned OFF by

turning PEND OFF

Operation of actuator

Not turned ON for

miss-pressing

Command position No.

PC1 to PC*

(PLCĺController)

Start signal CSTR

(PLCψController)

Positioning Completion

Signal

PEND

(ControllerψPLC)

Approach operation

Pressing

operation

Pressing

completion

Positioning by setting

of coordinate value

Movement by

positioning

width

Stop of

pressing

Pressing start position

100mm

Pressing end position

100 + 50 = 150mm

CSTR

Pressing operation

CSTR

Approach operation

CSTR: Start position

CSTR

Pressing operation

Pressing operation