INFICON IC6 Thin Film Deposition Controller User Manual

Page 116

5 - 8

PN

07

4-

50

5-

P1

F

IC6 Operating Manual

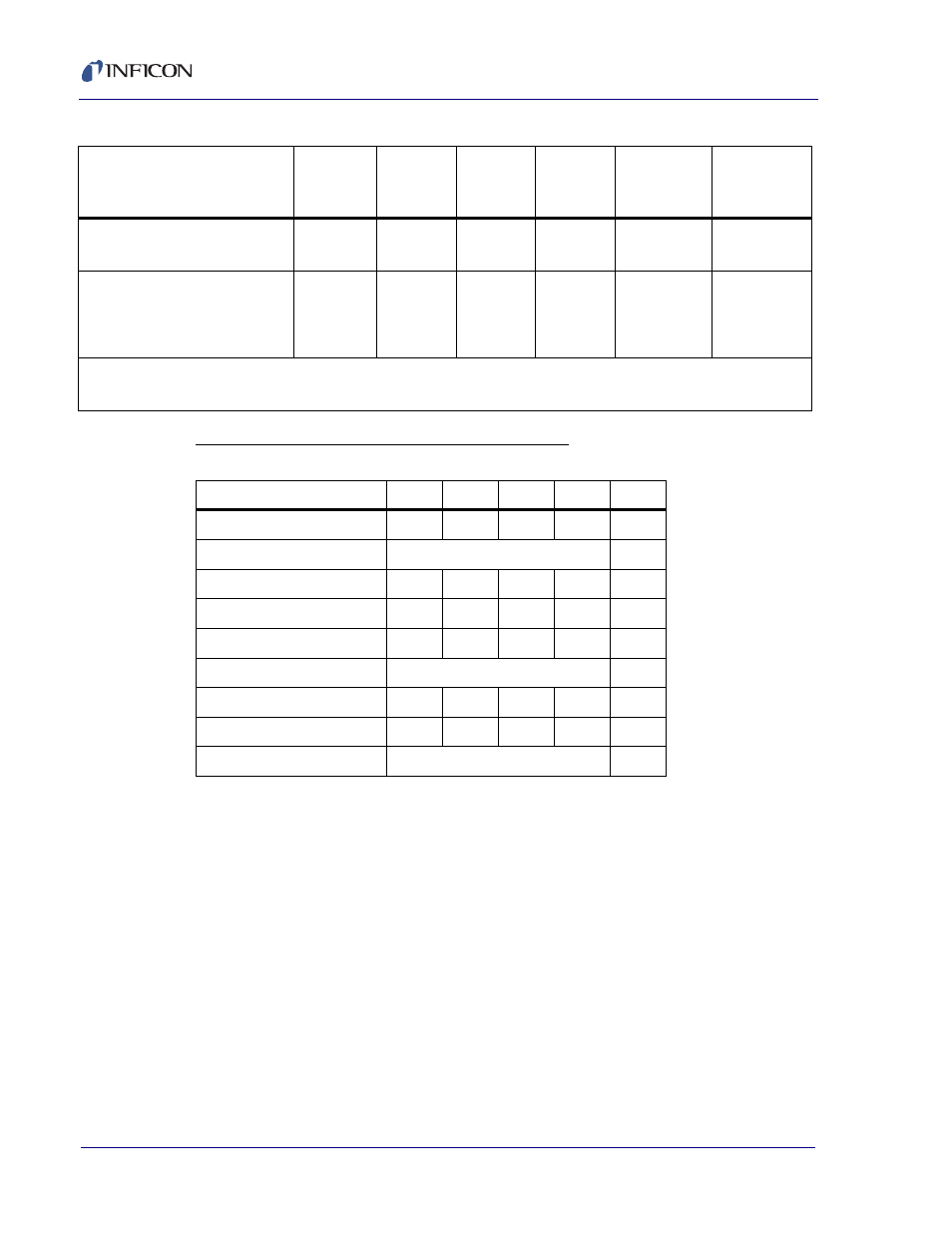

AGGREGATE RATE CALCULATION EXAMPLE

Displayed Rate = Applied Rate * Master Tooling * Sensor Tooling

Relative Weight = Sensor Weight /

Weights

Contribution Rate = Displayed Rate * Relative Weight

Aggregate Rate =

Contribution Rates. This is the rate that will be displayed on the

Operate screen.

The Displayed Rate is the rate for each sensor displayed on the Sensor Information screen.

It reflects the effects of Master Tooling and Sensor Tooling and is not affected by the Weight

parameter.

Regardless of which sensor fails, the aggregate rate will remain the same.

The following parameters expand from using one sensor when Multipoint is

OFF to using up to eight sensors when Multipoint is turned ON.

(SENSOR) FAILURE ACTION. . Unused (0), PostDp (1), Stop (2),

Suspnd (3), TimePw (4)

Applying the multiplier to all

future aggregate rate results:

Xtal Fail

10

10

4

10

1.25

If during the deposition the use

of the aggregate multiplier is

turned off, the aggregate rate

reverts back to:

Xtal Fail

10

10

4

8

not used

If the layer has not finished, the use of AGGREGATE MULTIPLY may be turned back on and the previously calculated

multiplier (in this case 1.25) will continue to be used.

Table 5-1 Aggregate multiplier effect (continued)

Condition of the deposition

Sensor

#1

Rate (Å)

Sensor

#2

Rate (Å)

Sensor

#3

Rate (Å)

Sensor

#4

Rate (Å)

Aggregate

Rate (Å)

Aggregate

Multiplier

Table 5-2 Aggregate rate example data

Sensor

1

2

3

4

Unit

APPLIED RATE

2

4

2.667

1

Å/s

MASTER TOOLING

200

%

SENSOR TOOLING

100

50

75

200

%

DISPLAYED RATE

4

4

4

4

Å/s

SENSOR WEIGHT

50

100

75

25

%

WEIGHTS

250

%

RELATIVE WEIGHT

0.2

0.4

0.3

0.1

N/A

CONTRIBUTION RATE

0.8

1.6

1.2

0.4

Å/s

AGGREGATE RATE

4

Å/s