Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 87

Offset Table and Setup

Chapter 3

3-19

The control can save all of the information that is entered in the tool offset

tables and the work coordinate system tables as a backup. This is

accomplished by the control generating a program consisting of G10

blocks. These G10 blocks contain the offset numbers and their respective

wear and geometry values. Any time your run this program, the set of

values contained in these G10 blocks replace the current values in the

offset tables. The G10 program can be saved in control memory.

This feature is very useful if the same tool or coordinate system offsets are

to be used on different machines. The same offset tables can be easily set

up by running this G10 program on other machines.

The offset table program can be saved in control memory as a program.

This is very useful if the same tools are to be used on different machines.

The offset tables can be easily set up by executing the same offset table

program on all the other machines.

Important: Once the control begins executing a G10 program that has

been previously generated, it clears any data that exists in

the offset table being updated by that G10 command. This

makes it impossible for a G10 block to simply add a few

offset values. A G10 program must load the entire offset

table each time it is run. Tool geometry and tool wear

tables are separate offset tables. Loading data into one does

not clear the other.

To back up the offset tables, follow these directions:

1.

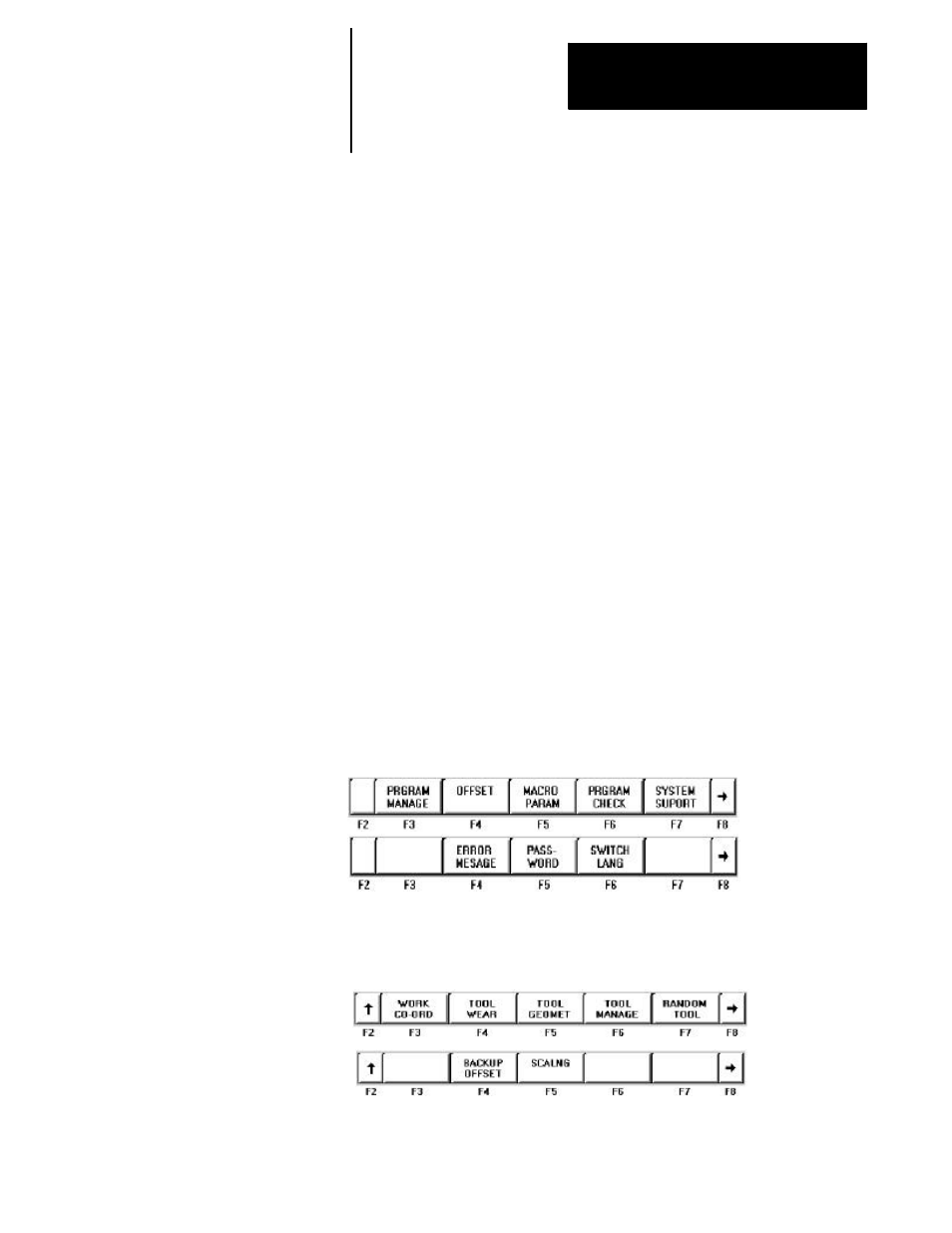

Press the

{OFFSET}

softkey.

(softkey level 1)

2.

Press the

{BACKUP OFFSET}

softkey. The control displays the backup

offset screen shown in Figure 3.10.

(softkey level 2)

3.4

Backing Up Offset Tables