Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 363

Axis Motion

Chapter 14

14-5

You must establish a plane before the control performs the correct arc.

This should have been done by your system installer, typically assigning

the Z and X axes to the G18 plane. This becomes the default plane that the

control assumes when:

power is turned on

E-Stop is reset

the control is reset

Circular interpolation can be performed in the absolute (G90) or

incremental (G91) mode.

Important: S--Curve Acc/Dec mode is not available with circular

interpolation mode.

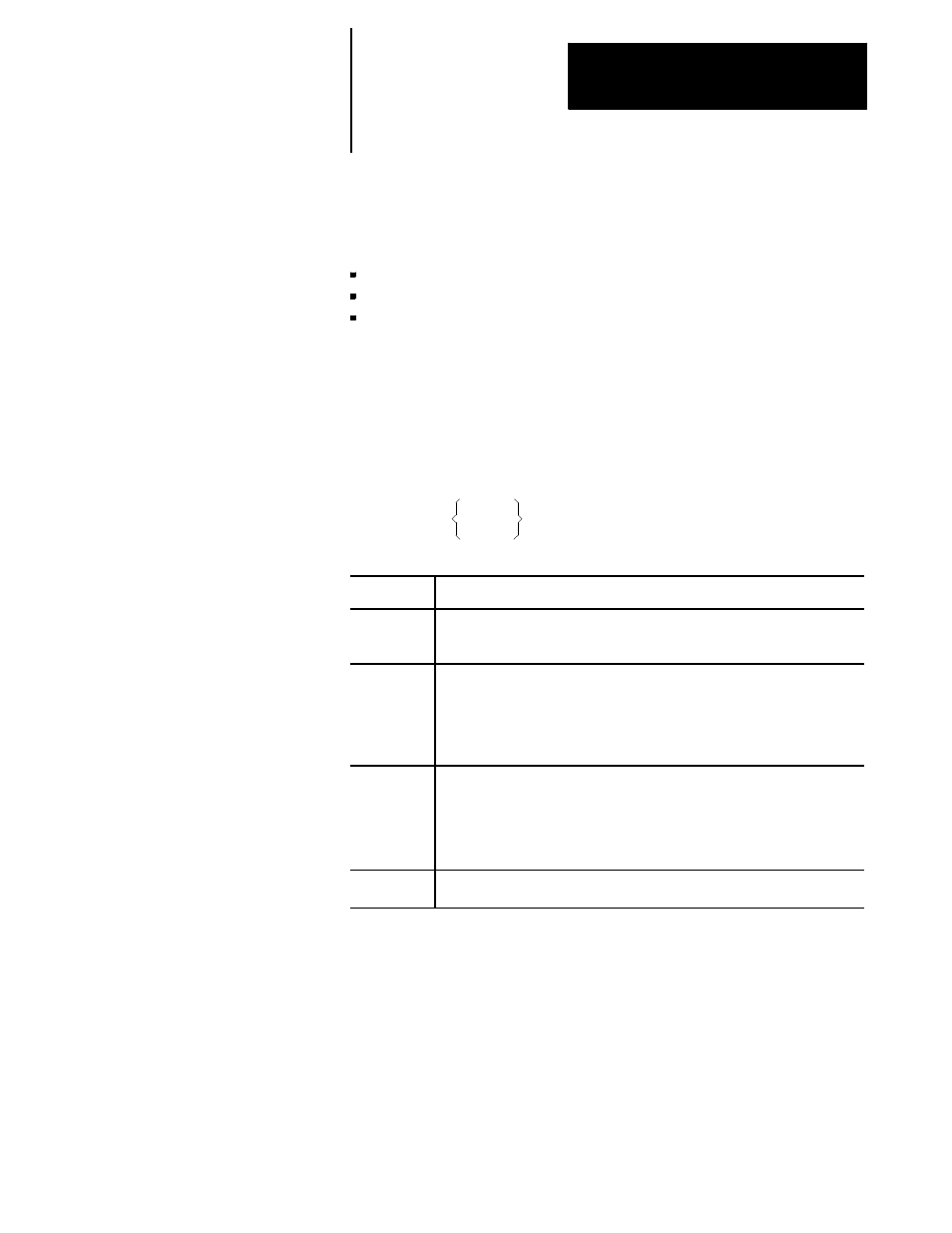

The format for circular interpolation in the ZX plane is:

{G02} X__ Z__

I__ K__

F__ ;

G03

R__

Where :

Is :

X, Z

In absolute (G90) mode, these are the work coordinate values of the end point.

In incremental (G91) mode, these are the positions of the end point in reference

to the start point.

I, K

These determine the position of the arc center. They are the incremental

distance on each axis from the start point of the arc to the center point. These

values are always incremental, regardless of the established positioning mode

(absolute or incremental). I is parallel to X axis, and K is parallel to Z axis;, but

his can be configured in AMP. These are not necessary if programming the R

parameter.

R

Rather than defining a center with I, K, the option exists to define an arc radius

using R. The sign of this entry determines the arc centerpoint location. If R is

programmed as a positive value, the centerpoint is located so that an arc less

than 180

°

is generated. If R is programmed as a negative value, the centerpoint

is located so that an arc greater than 180

°

is generated. Refer to Figure 14.5 for

an example.

F

Another option is to enter a feedrate tangential to the arc. If omitted, the control

uses the feedrate active prior to this block.