Compound turning routines – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 565

Chapter

24

24-1

Compound Turning Routines

Compound turning routines are routines that make multiple passes across

the workpiece to cut a specific contour into the workpiece. A set of

blocks, called contour blocks, define the final contour shape of the

workpiece. A calling block, containing one of the following G-codes, sets

the parameters for the execution of the routine and defines what blocks are

used as the contour blocks.

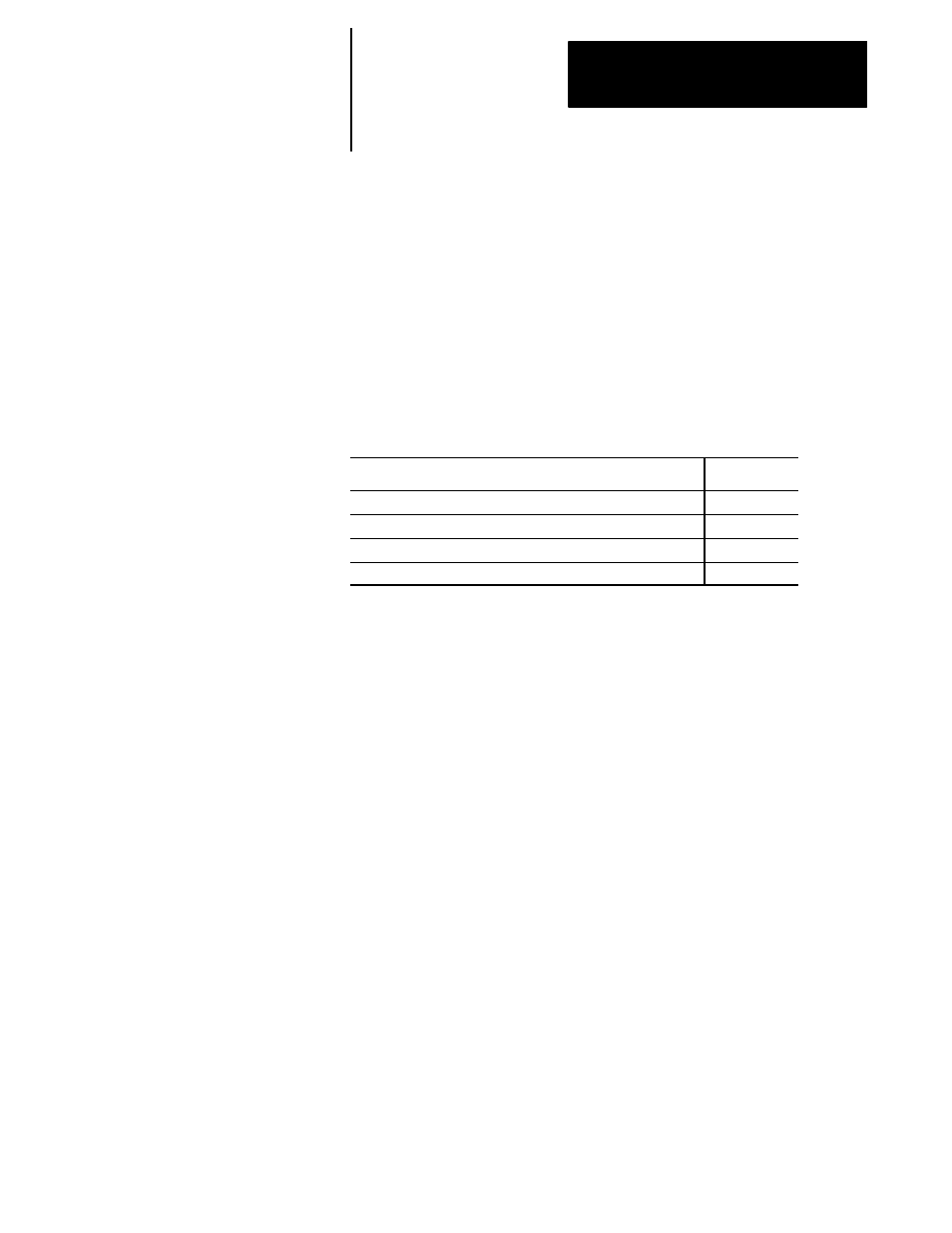

Topic:

On page:

G73 O.D. and I.D. Roughing Routine (along Z-axis)

24-2

G74 Rough Facing Routine (along X-axis)

24-15

G75 Casting/Forging Roughing routine (parallel to work shape)

24-29

G72 O.D. and I.D. Finishing Routine

24-35

Important: Descriptions in this chapter are written assuming the control is

in the G18 plane and that plane has been defined as the ZX plane. If your

system has a different plane active, operation of these features is different.

Parameters are defined here assuming Z is the first axis in the plane, and X

is the second axis in the plane. If, for example, the XZ plane is the

currently active plane, descriptions in this document should be interpreted

accordingly (i.e., Z axis description applies for X axis and X axis

description applies to Z axis. Refer to your system installer’s

documentation for details on the plane definitions on your system.

If you are using a dual--processing system, refer to page 30-14 for details

about spindle control.

Important: Any rapid motions that are generated by the execution of a

compound turning routine are always performed using exponential

ACC/DEC. Refer to chapter 18. Compound turning routines ignore the

AMP parameter that determine the ACC/DEC type normally used for

rapid moves. If AMP parameters have not been configured to properly

allow rapid motions using exponential ACC/DEC, a SERVO AMPLIFIER

FAULT error may be generated during the execution of these routines.

24.0

Chapter Overview