1 altering external offset (g10l2) – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 317

Chapter 11

Coordinate System Offsets

11-11

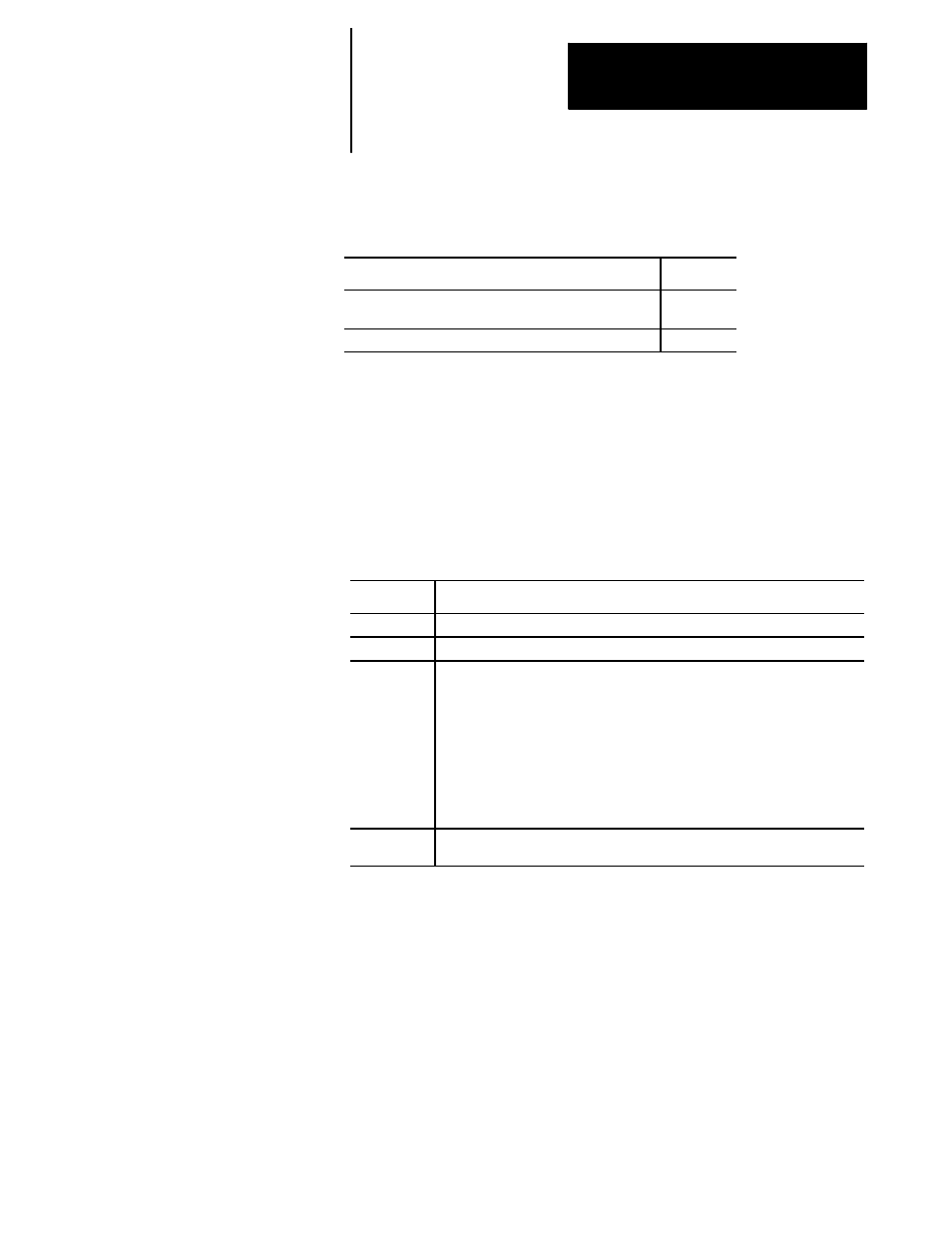

There are 3 methods to change the value of an external offset in the work

coordinate system table. Two methods can be found in the following

sections:

Method:

Chapter:

manually alter the external offset value in the work

coordinate system table

3

alter the paramacro system parameter values 5201- 5206

28

The third method, and the one described in this section, alters the external

system table through G10 programming. Changing these values in the

table using any of these methods does not cause axis motion. It does

immediately shift the active coordinate system by the amount entered.

The values entered into the external offset are added to the work coordinate

system zero point values each time a work coordinate system is called.

The format for altering the external offset using G10 is:

G10 L2 P0 O__ X__ Z__;

Where :

It :

L2

tells the control that you want to alter the coordinate system tables.

P0

designates the external offset as the offset to update.

O__

specifies whether the value entered for the diameter axis is a radius or diameter

value. (O is non-modal.)

O1

=value entered for the diameter axis is a radius value.

O2

=value entered for the diameter axis is a diameter value.

Important:

If you program O1 or O2 in a G10 code, the G10 code is not

affected by a previously programmed G07 or G08 (radius/diameter

programming). However, if no O-code is specified, or if the O-code is out of

range (for example, O3), then the G10 code is affected by a G07/G08.

X_Z_

specifies the location of the zero point of the specified work coordinate system

relative to machine coordinate system.

When you execute this block, the control immediately shifts the currently

active work coordinate system by the new external offset amount.

Example 11.4 and Figure 11.9 illustrate how the work coordinate system is

shifted using G10.

11.3.1

Altering External Offset

(G10L2)