Offset compatibility considerations – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 858

Allen-Bradley 7300 Series CNC

Tape Compatibility

Appendix D

D-8

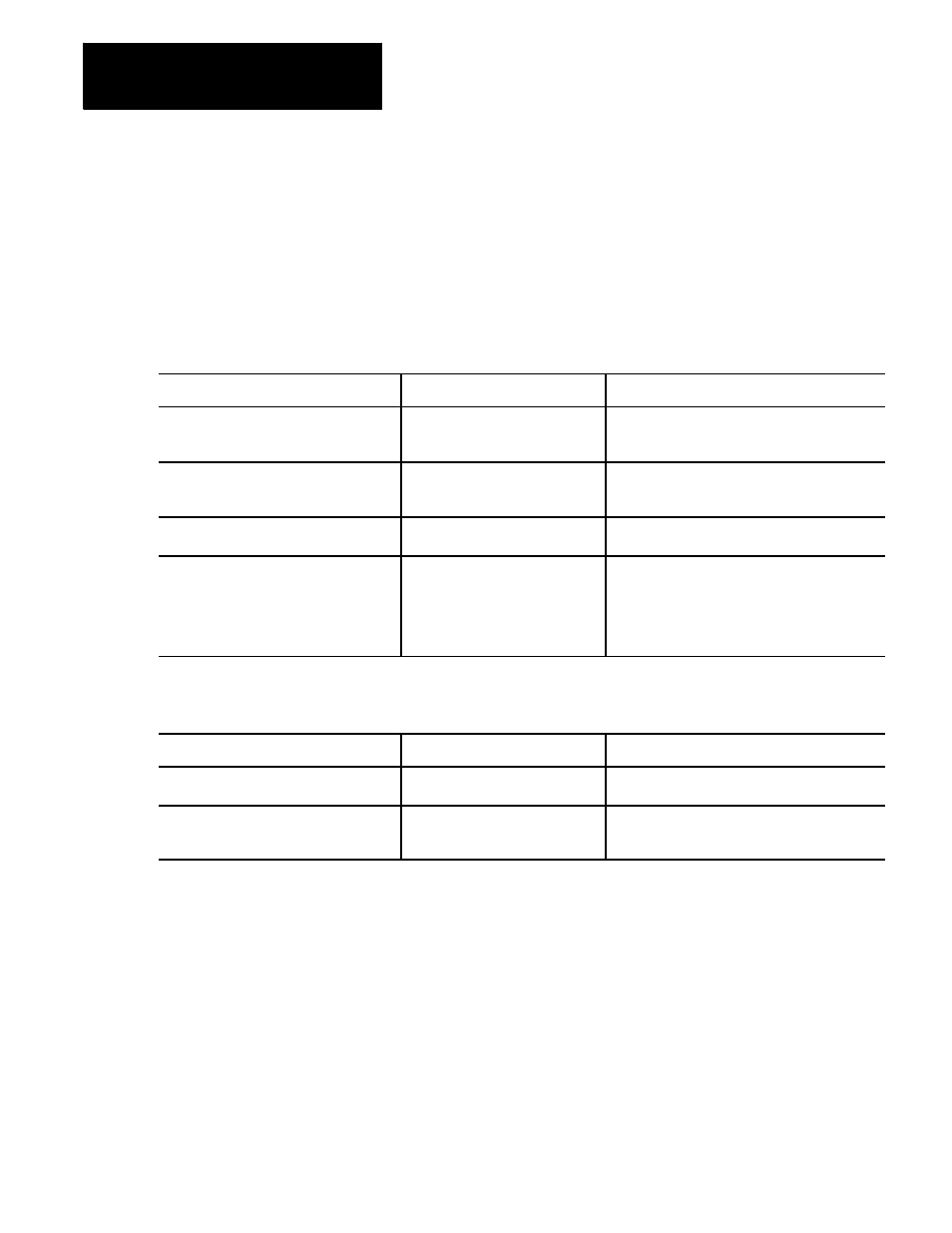

Tool Length Offset

When the control is in 7300 mode, tool length offsets are activated in the

same manner as on the 7300. The control supports 1- through 4-digit

T-words, and through AMP configuration, you have the flexibility of

specifying how the control activates offsets.

We recommend that you use this set-up when running your control in 7300

mode:

Set This Tool Length Offset Parameter:

To:

Explanation:

Tool Geometry Mode (AMP [202]):

immediate shift/immediate move

once the offset is programmed, the geometry offset

is activated immediately and the coordinate system

gets shifted immediately.

Tool Wear Mode (AMP [203]):

immediate shift/immediate move

once the offset is programmed, the wear offset is

activated immediately and the coordinate system

gets shifted immediately.

Tool Offset Cancel (AMP [204]):

cancel geometry & wear

both the geometry and wear offsets are cancelled

when the active offset is cancelled.

T-code Format (AMP [205]):

2-digit geometry & wear

The 2 right-most digits are used for geometry &

wear; and the leftover are used for tool number.

Example: T10 activates geometry offset 10 and

wear offset 10 on tool number 0.

Example: T915 activates geometry offset 15 and

wear offset 15 on tool number 9.

If the Tool Life Management option is present, set the following AMP

parameters for 7300 compatibility:

Set This Tool Length Offset Parameter:

To:

Explanation:

Tool Number/Group Boundary (AMP [131]):

9799

specify the division between ordinary tool numbers

and tool life groups.

T-word Programming Method (AMP [132]):

next Tool in T-word

for this method, the T-word to be activated is

programmed in a block that does not contain an

M06.

For systems with the Tool Life Management option, the T-word is limited

to four digits in the range of 1 to 9799.

Refer to the AMP manual for details on any of the above AMP parameters.

Important: When 7300 mode is active on the control, automatic tool

changing requires the proper PAL interface and may require changing the

AMP parameters described above. The random tool feature of the control

is also available to interface with special tool changers.

Offset Compatibility

Considerations