Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 429

Programming Feedrates

Chapter 18

18-3

For outside arc paths, the speed of the tool tip relative to the part surface

can be determined using the following formula:

R

p

Tool tip speed

=

F

x

----

R

c

Where :

Is :

F

programmed feedrate

R

c

radius of the arc measured to the center of the tool radius

R

p

programmed radius of the arc

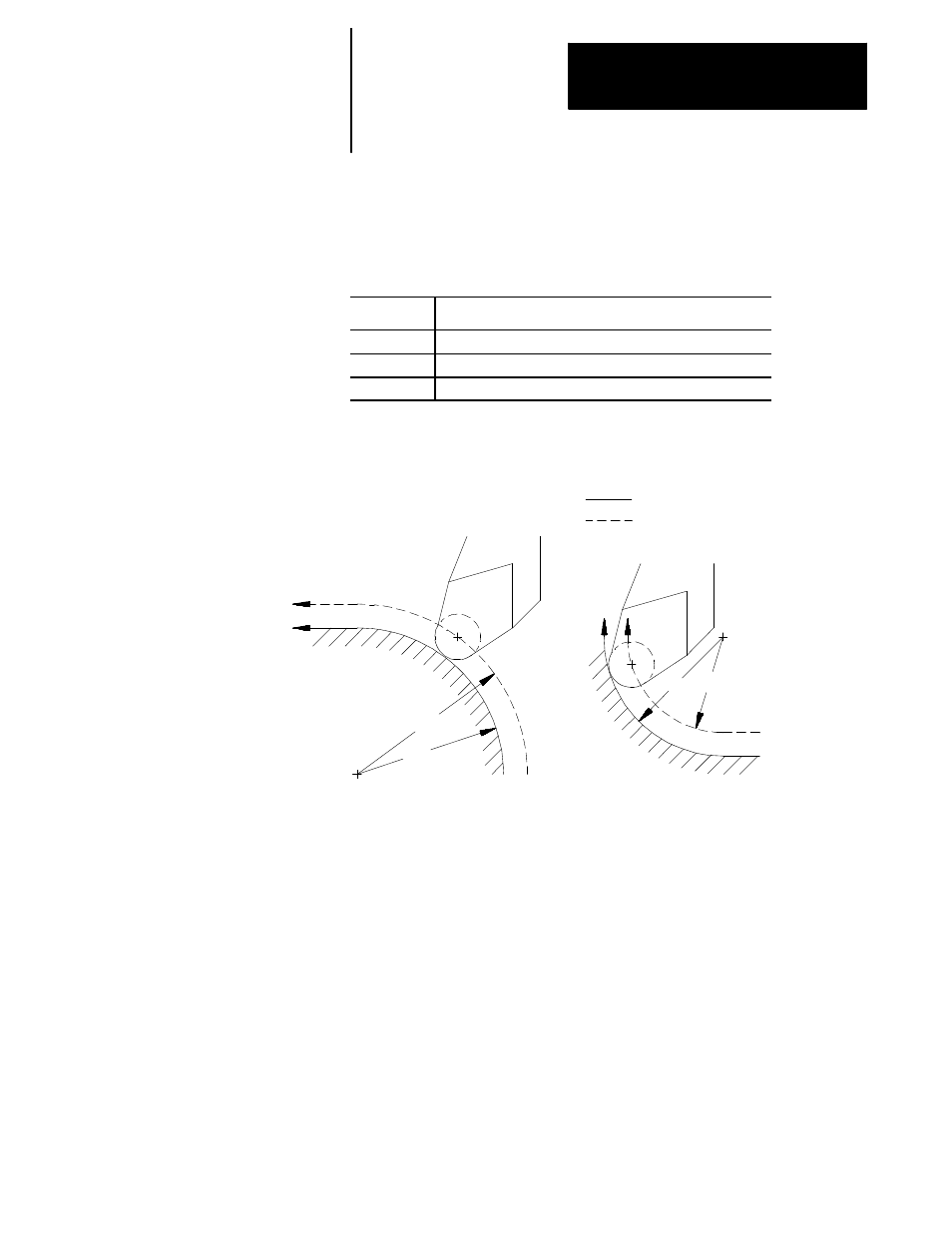

Figure 18.2

Inside and Outside Arc Feedrates with TTRC

programmed tool path

tool radius center path

Cutting

outside arc

R

c

R

p

R

p

R

c

Cutting

inside arc

R

c

> R

p

F as programmed

R

c

< R

p

F is reduced

For inside arc paths, the control automatically maintains the programmed

feedrate at the tool tip. The actual tool radius center feedrate reduces as

needed through the arc path, and then it returns to the programmed feedrate

after the arc is completed.

During inside arc paths, the control decreases the tool radius center

feedrate by the ratio of R

c

/R

p

. If the R

c

value is very small compared to

R

p

, as in the case of a small arc being cut with a large diameter tool, the

value of R

c

/R

p

is nearly zero, and the tool radius center feedrate becomes

excessively small.

To avoid this problem, your system installer must set a minimum feed

reduction percentage (MFR) in AMP. This sets a minimum feedrate to be

used whenever the value of R

c

/R

p

is very small. If R

c

/R

p

< MFR, the

control reduces the tool radius center feedrate no more than the MFR

percentage.