Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 311

Chapter 11

Coordinate System Offsets

11-5

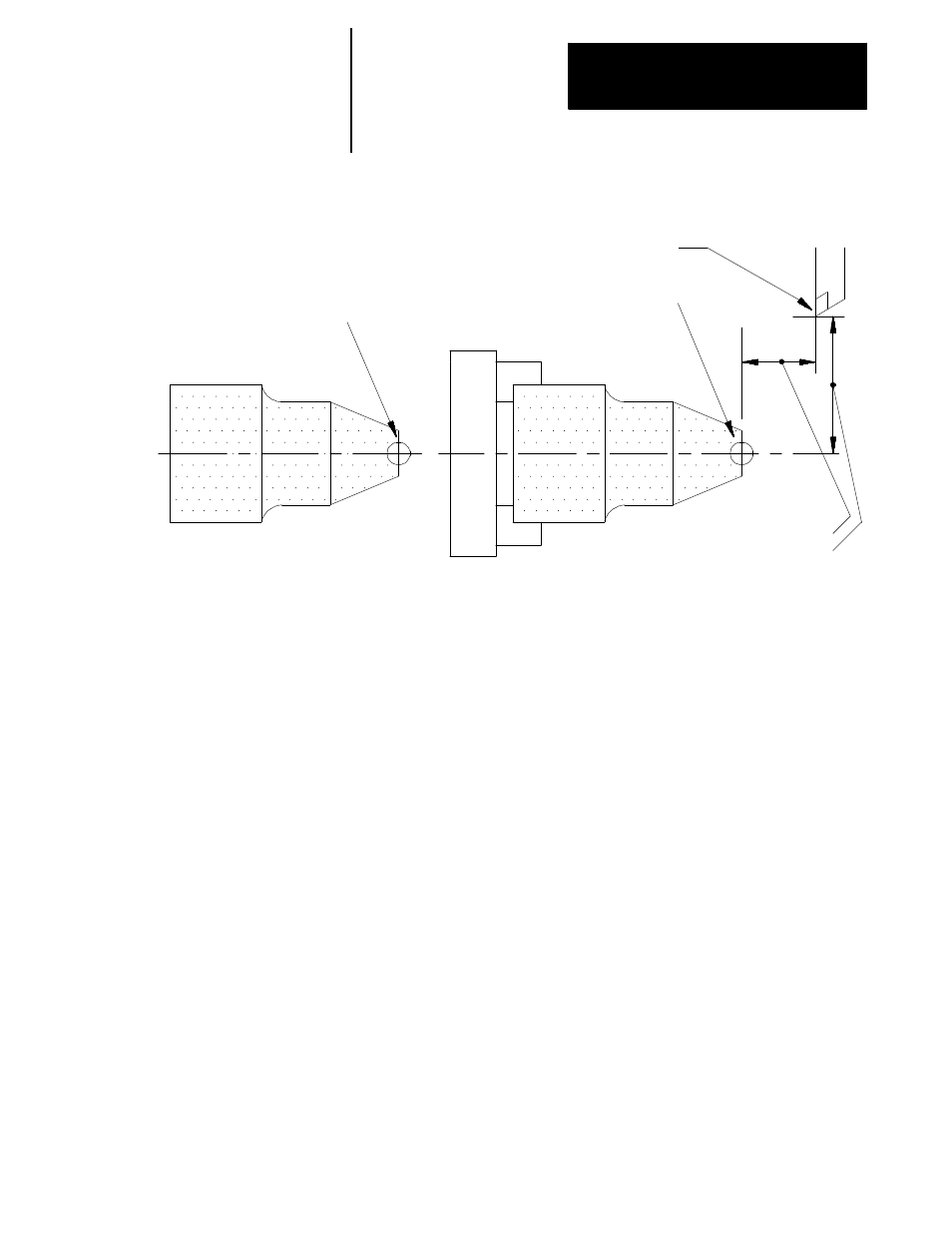

Figure 11.3

Work Coordinate System

Zero point on

the part drawing

Workpiece

Chuck

Workpiece

Zero point on the work

coordinate system

Tool position at

machine coordinate zero point

Z Distance to be designated

X Distance to be designated

There are 7 preset work coordinate systems selected using G54 - G59.3.

The required work coordinate system can be selected by specifying any of

these G-codes in the program.

Work coordinate systems called out by G54 - G59.3 have zero points that

you enter in a work coordinate system table (see page 4.3). These zero

points are in the form of offset values from the machine coordinate system

zero point.

The control establishes the machine coordinate system immediately after

you complete the machine home operation The default work coordinate

system, determined in AMP by your system installer, is activated

simultaneously. The default work coordinate system is established when

you execute a control reset operation, E-STOP, G92.1, or power up. The

default work coordinate system is the sum of the external offset value (if

any), and the offsets of the default coordinate system selected in AMP

(G54-G59.3 or none). If the default coordinate system is selected as none,

the default work coordinate system is simply the external offset (if any).

This manual assumes G54 to be the default coordinate system and no

external offset has been entered.