1 feedrates applied during ttrc – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 428

Programming Feedrates

Chapter 18

18-2

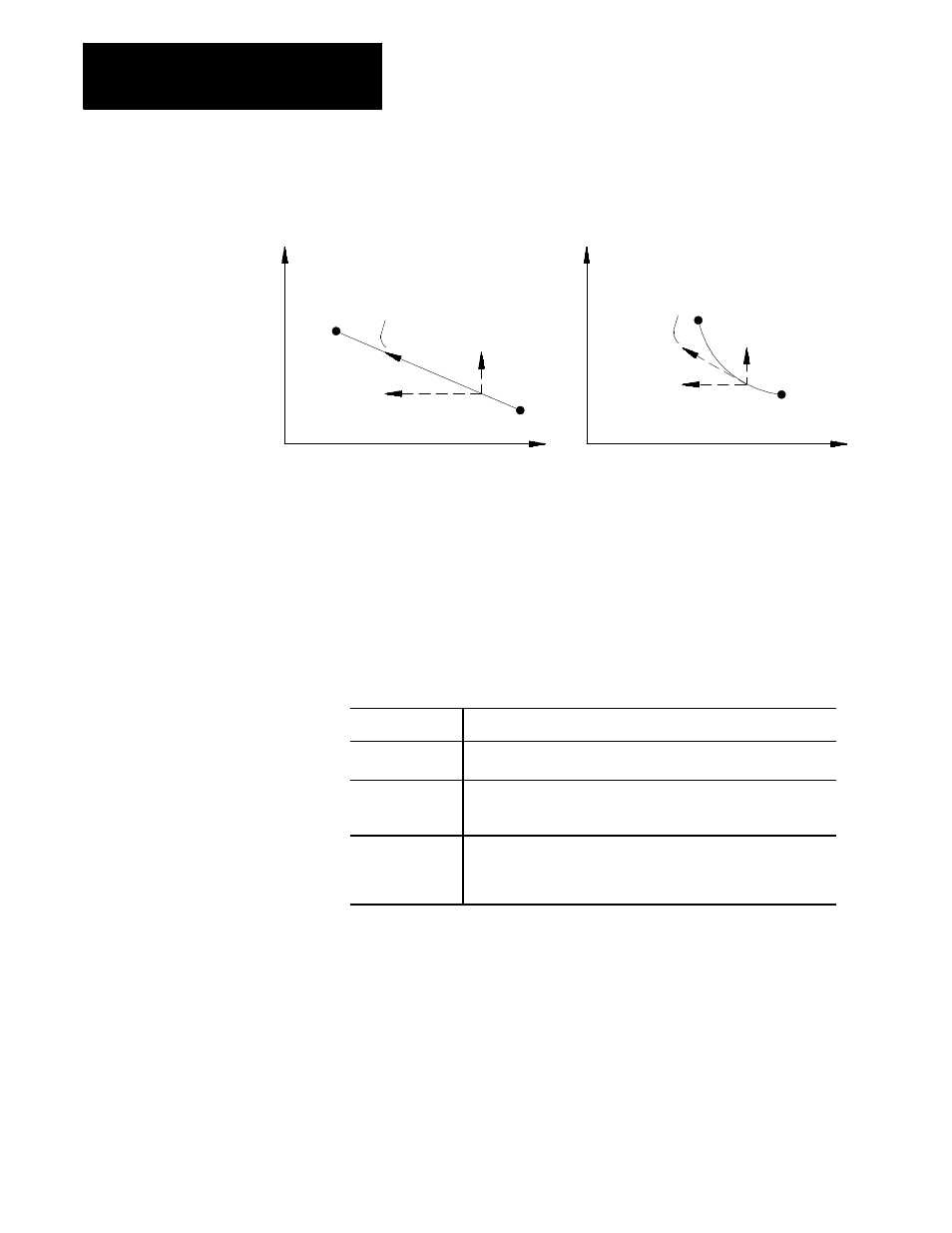

Figure 18.1

Programming a Tangential Feedrate

Z

Z

X

X

Linear interpolation

Circular interpolation

programmed

feedrate

X axis

feedrate

start

point

Z axis

feedrate

end

point

programmed

feedrate

end point

X axis

feedrate

start

point

Z axis

feedrate

For example, if a feedrate is programmed as F100.0 millimeters per

minute, and a linear move is made from X0, Z0 to X10, Z10, the feedrate

along that 45 degree angular path would be 100.0 mmpm. The actual

feedrate of each axis is approximately 70.7 millimeters per minute.

When the cutting tool is offset from a programmed path (as in the case of

TTRC), the programmed feedrate is applied to the center of the tool radius

for all linear and outside arc paths.

For these paths:

The result:

linear

is not significant because the speed of the tool tip relative to the part

surface remains the same as the programmed feedrate.

outside arc

speed of the tool tip relative to the part surface is less than the

programmed feedrate. This generally causes no problem and so the

control does not take corrective action.

inside arc

speed of the tool tip relative to the part surface would be greater than

the programmed feedrate. Since this could cause excessive tool

loading and poor cutting performance, the 9/Series control

automatically takes corrective action.

18.1.1

Feedrates Applied During

TTRC