1 tool dimensional parameters – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 71

Offset Table and Setup

Chapter 3

3-3

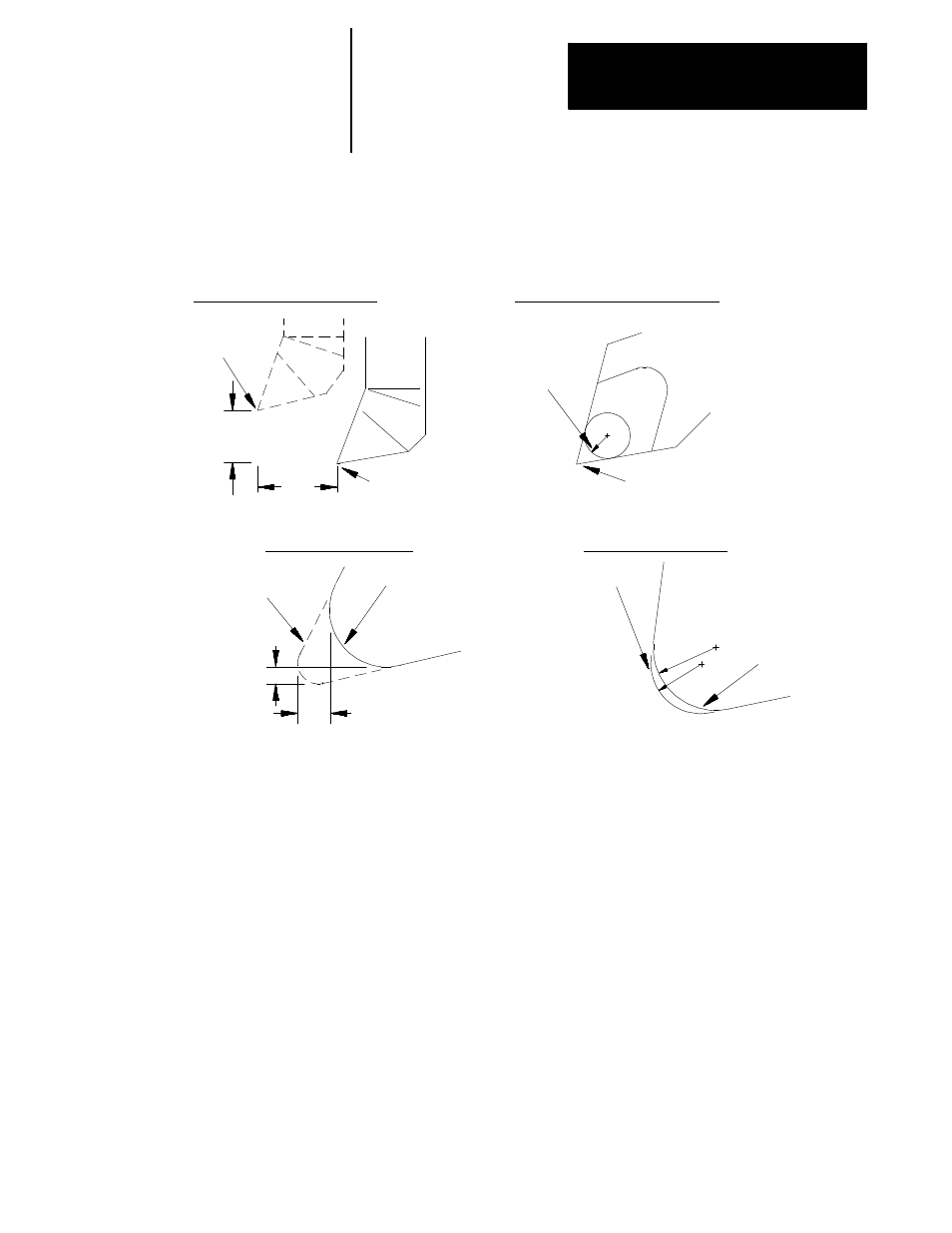

Figure 3.2

Tool Dimensional Offsets

Worn cutting

edge

R’

R

Cutting edge before

tool wear

Worn cutting

edge

Cutting edge before

tool wear

Z

X/2

Z

X

R = R’- R

Actual tool

position

Assumed tool

position

Actual tool

tip point

R

TOOL WEAR, RADIUS

TOOL WEAR, LENGTH

TOOL GEOMETRY, LENGTH

TOOL GEOMETRY, TIP RADIUS

Assumed tool

tip point

Tool Length (Tool Geometry Table)

The dimensions, entered into the tool geometry for length, reflect the

distance from the tool tip to the gauge point on the tool holder. This gauge

point actually moves to the coordinates programmed in a part program, if a

tool offset is not activated.

We use the term “gauge point” to define the precise point on the turret

from which all programmed tool paths originate. Offsets refer to the

distance from this gauge point to the tip or edge of the tool that contacts

the part being cut.

Use the tool length offset function to compensate for the difference

between the tool position as mounted in the turret and the tool position

assumed in writing a program. By using the tool length offset functions

along with tool orientation data, a programmer can write a part program

without further concern for tool position due to mounting. Measure offset

values for each axis to allow for the difference between the assumed and

actual cutting tool locations.

3.1.1

Tool Dimensional

Parameters