Using a 9/series dual-processing system – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 741

Chapter

30

30-1

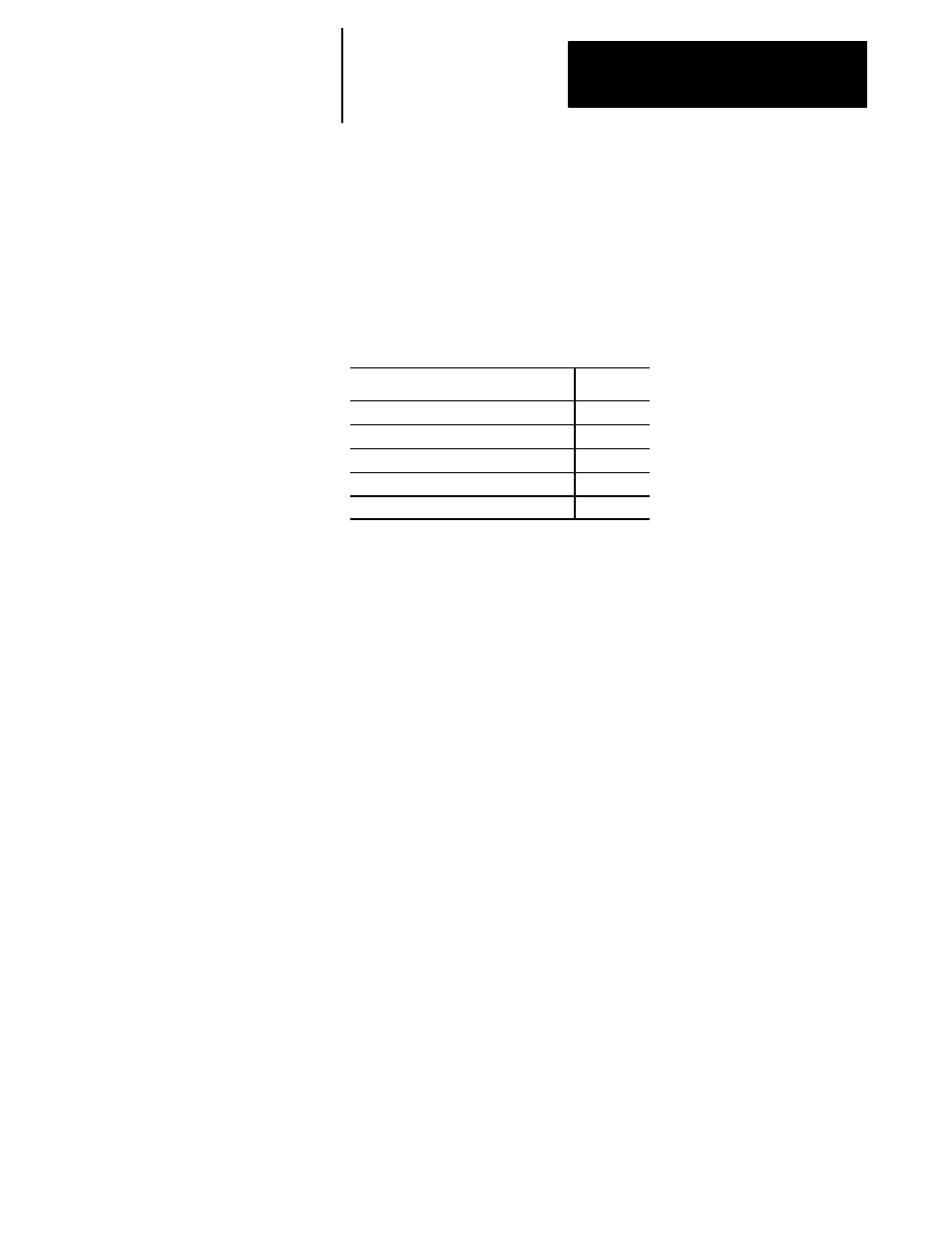

Using a 9/Series Dual-Processing System

Read this chapter to learn general information related to programming and

operating a dual-processing system. Major topics in this chapter cover:

Topic:

On page:

Definition of a dual-processing system

30-1

Operating a dual-processing system

30-2

Synchronizing multiple part programs

30-7

Spindle control for dual-processing

30-12

Using interference checking

30-19

A dual-processing system is basically two machine tools in one. One

9/Series control is capable of executing two separate part programs,

controlling separate machining axes. Offsets, tool management, axis

feedrate are independent for each program. Each of these two

independent systems is called a process. The 9/Series control is capable of

running two processes simultaneously.

You can configure the 9/Series dual-processing lathe to run on a wide

variety of machines. For dual-processing to function correctly, your

system installer must make certain AMP and PAL configuration

considerations. Refer to the 9/Series CNC AMP and PAL Reference

Manuals or your system installer’s documentation for details.

This chapter focuses on a 4-axis lathe, sometimes called a dual-turret lathe.

Many other applications, like a completely separate twin-turning machine

or a dual-spindle lathe are possible and easily configured by your system

installer. Operation of these other applications must be interpreted from

the dual-turret application presented in this manual.

Your system installer selects the lathe G-code system your dual-process

lathe is using. Both processes must use the same G-code system. Refer to

your system installer’s documentation for details.

30.0

Chapter Overview

30.1

Defining of a

Dual-Processing System