The format for the g28 block is, Figure d.1 illustrates these parameters – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 854

Allen-Bradley 7300 Series CNC

Tape Compatibility

Appendix D

D-4

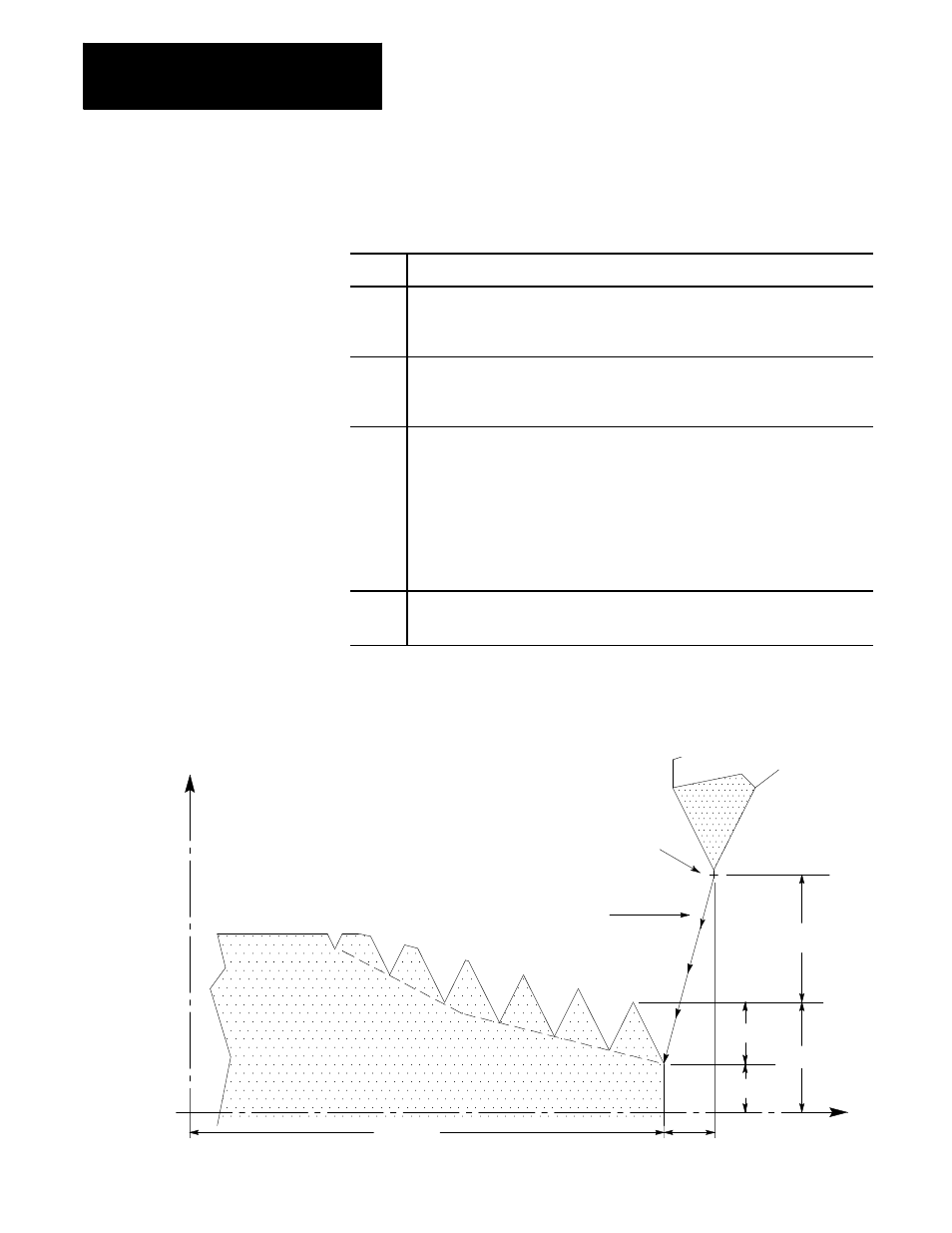

The format for the G28 block is:

G28__D__X__Z__F

Where: Specifies:

D

final threading depth or roughing depth. For Absolute Programming mode (G90), this

parameter is programmed as an X axis position. For Incremental Programming mode

(G91), this parameter is programmed as a distance measured parallel to the X axis from

the initial work surface.

X

depth of first thread cutting pass or first roughing pass. For Absolute Programming

mode, the initial depth is programmed as an X axis position. For Incremental

Programming mode, this initial depth is programmed as a distance measured parallel to

the X axis from the initial work surface.

Z

the distance between the starting point and the infeed endpoint on the Z axis. Not

programming a Z or programming a Z that does not create any axis motion results in a

plunge infeed. A plunge infeed moves the tool directly into the part with no Z component

in the move.

Programming a Z that is different than the starting point Z location generates a tapered

infeed. For threads that are cut with tapered infeed, the tool is fed into the part at an

angle comprised of both X and Z motions. The angle is determined by the linear

intersection of the start point and the endpoint. The endpoint is determined by this

parameter on Z axis and final depth is determined by D.

F

feedrate of the plunge or compound infeed. The infeed rate is programmed in the

units/inches per minute (IPM) in the inch mode, or millimeters/minute (MMPM) in the

Metric mode.

Figure D.1 illustrates these parameters.

Figure D.1

G28 Multi-pass Thread Cutting Parameters

(Absolute/Incremental Programming Mode)

X

Z

X abs.

D abs.

X inc.

Z abs.

Z inc.

D inc.

Starting point

1st pass

2nd pass

3rd pass

Tapered infeed