Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 486

Tool Tip Radius Compensation (TTRC)

Function

Chapter 21

21-2

Figure 21.1

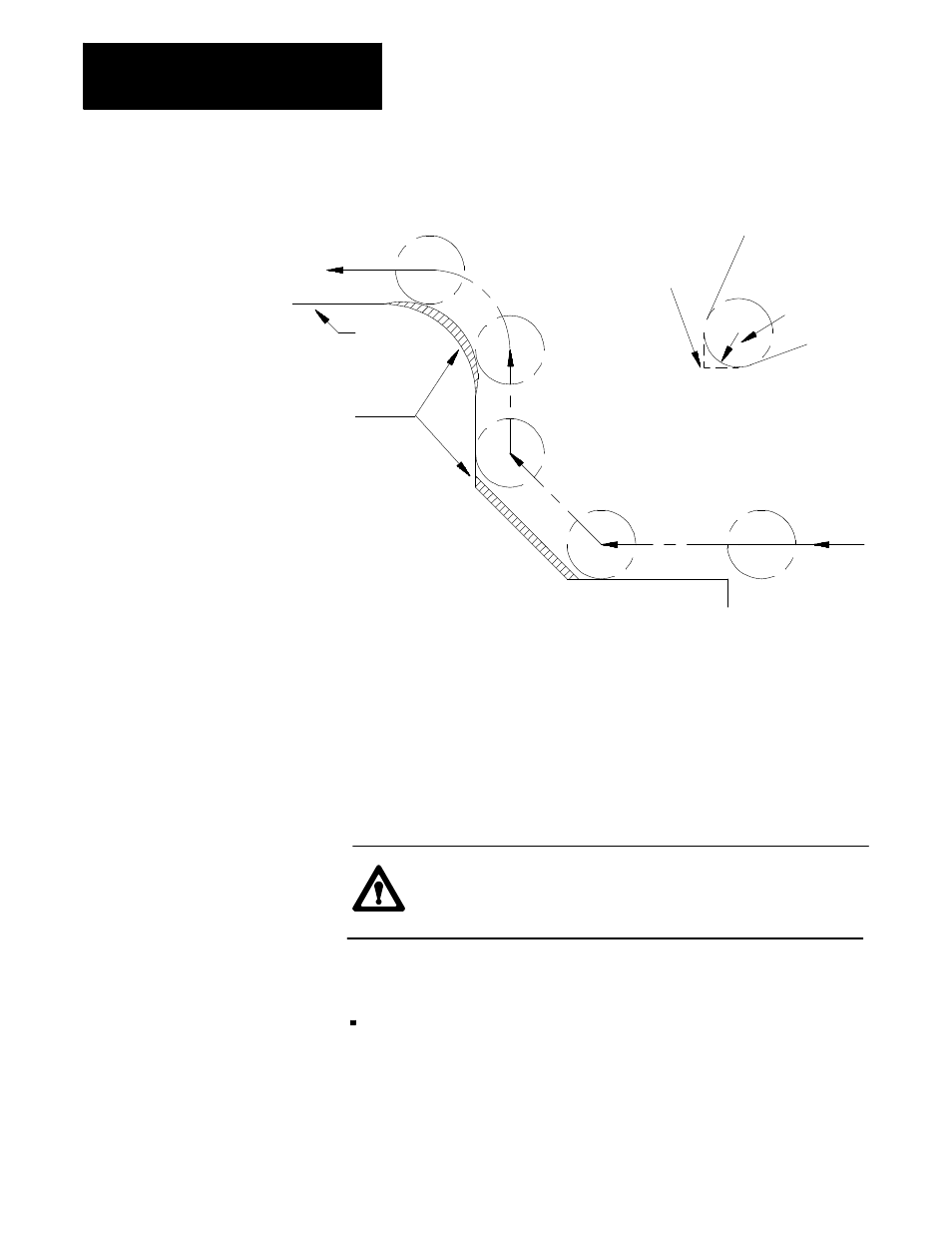

Taper and Arc Cutting Without TTRC

Without TTRC active,

control assumes tool

has a perfect point

Actual tool

tip radius

Cutting

tool

Part

profile

Material left uncut

due to radius of

tool tip

Put the radius of the tool and tool orientation data into the offset tables in

advance. This function lets the control use the same program to produce

the same workpiece, regardless of the radius of the tool that does the

cutting.

This feature also uses tool orientation data taken from the tool geometry

table. You need this tool orientation to compensate for inaccuracies that

can occur from difficulties in measuring tool tip diameter because of a tool

mounting position. If this is not a factor, make sure all tool orientations

use an orientation of either 0 or 9.

CAUTION: If you use a 2-turret lathe, be aware that the X tool

offset and the tool orientation values will be opposite of the A

turret values for the second mirrored (B).

We use these terms in this section:

inside ---- Refer to an angle between two intersecting programmed tool

paths as inside if, in the direction of travel, the angle measured

clockwise from the second tool path into the first is less than or equal

to 180°. See Figure 21.2. If one or both of the moves are circular, the

angle is measured from a line tangent to the tool path at their point of

intersection.