Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 493

Tool Tip Radius Compensation (TTRC)

Function

Chapter 21

21-9

The generated block between the two tool paths can be programmed as

linear or circular with these G-codes:

G39(or G39.1);

Where :

Causes:

G39

linear transition blocks. If neither G39 or G39.1 is programmed, G39

is the default. This command is modal.

G39.1

circular transition blocks. When cutting straight line-to-arc or

arc-to-straight line moves, the generated block will always be linear,

and the G39.1 will be ignored. This command is modal.

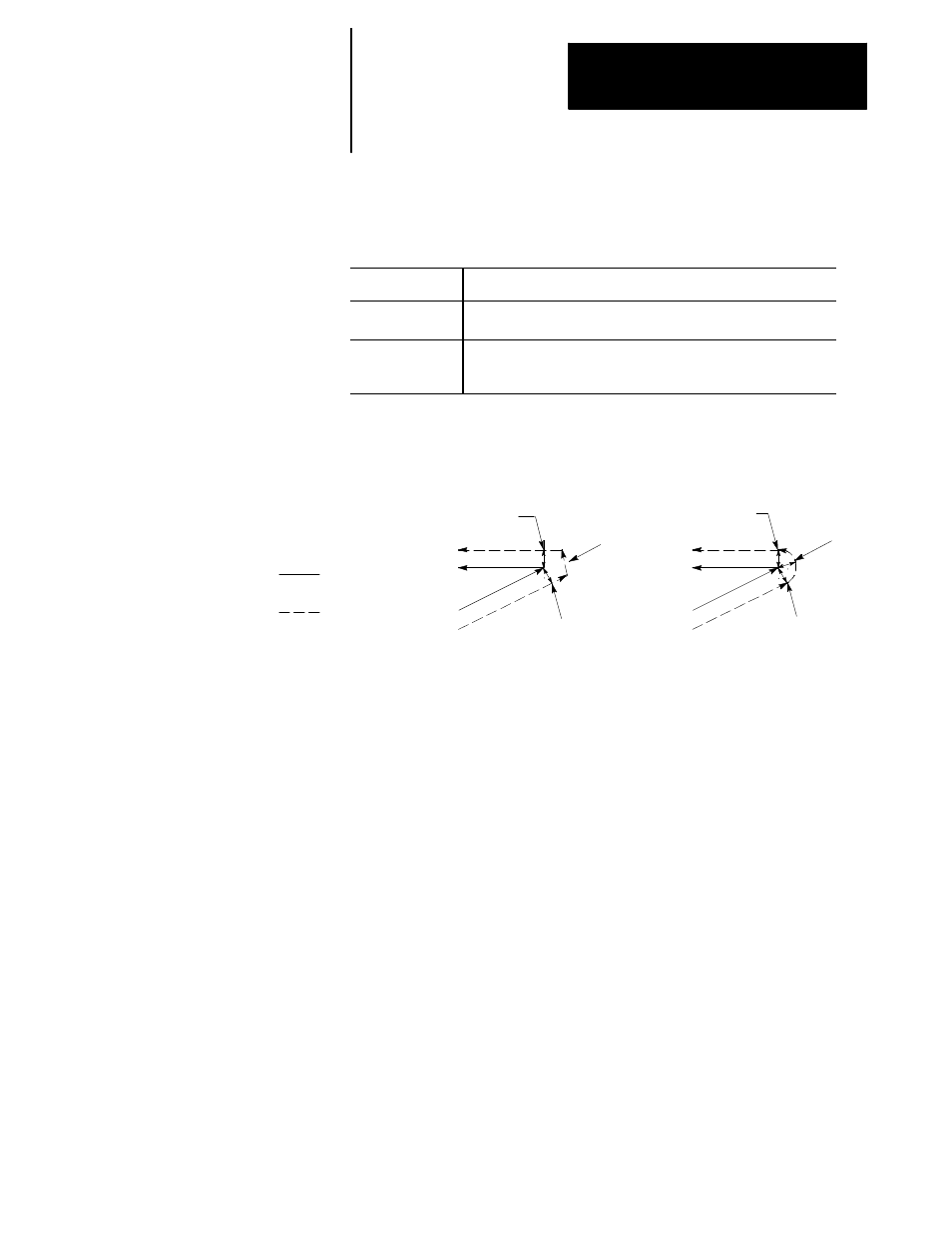

Figure 21.6

TTRC Generated Blocks (G39 vs G39.1)

G39 (Linear generated block)

End of

1st cut

Start of

2nd cut

r

r

r

block

generated

1st cut

Start of

2nd cut

G39.1 (Circular generated block)

r

r r

Linear

block

generated

Circular

r

Programmed

path

G42 Tool path

Tool radius

r =

End of

G39 or G39.1 can be programmed in any block. However, they must be

programmed in or before the block that causes a TTRC generated block.

Important: For linear generated blocks, your system installer can define a

minimum block length in AMP. If the generated move length is less than

the system-defined minimum block length, no generated block is created.

The tool path proceeds to the intersection of the two compensated paths. If

the generated move length is equal to, or greater than, the system-defined

minimum block length, a generated block is created.

Throughout this chapter, we show drawings where a generated block is

created. Both G39 and G39.1 are shown in these drawings where

applicable.