Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 83

Offset Table and Setup

Chapter 3

3-15

2.

Activate an offset number as follows:

Press This softkey:

To activate:

the {TOOL GEOMET}

a tool geometry offset number

the {TOOL WEAR}

tool wear offset number

The tool offset table is displayed. Currently active offset values

(if any) are indicated with an * to the right of the offset number.

3.

Move the cursor on the offset table until the desired offset is shown in

reverse video. Only one geometry offset and one wear offset number

may be active at the same time.

4.

Press the

{ACTIVE OFFSET}

softkey when the desired offset is

selected. The tool offsets are made active as described in

chapter 20.

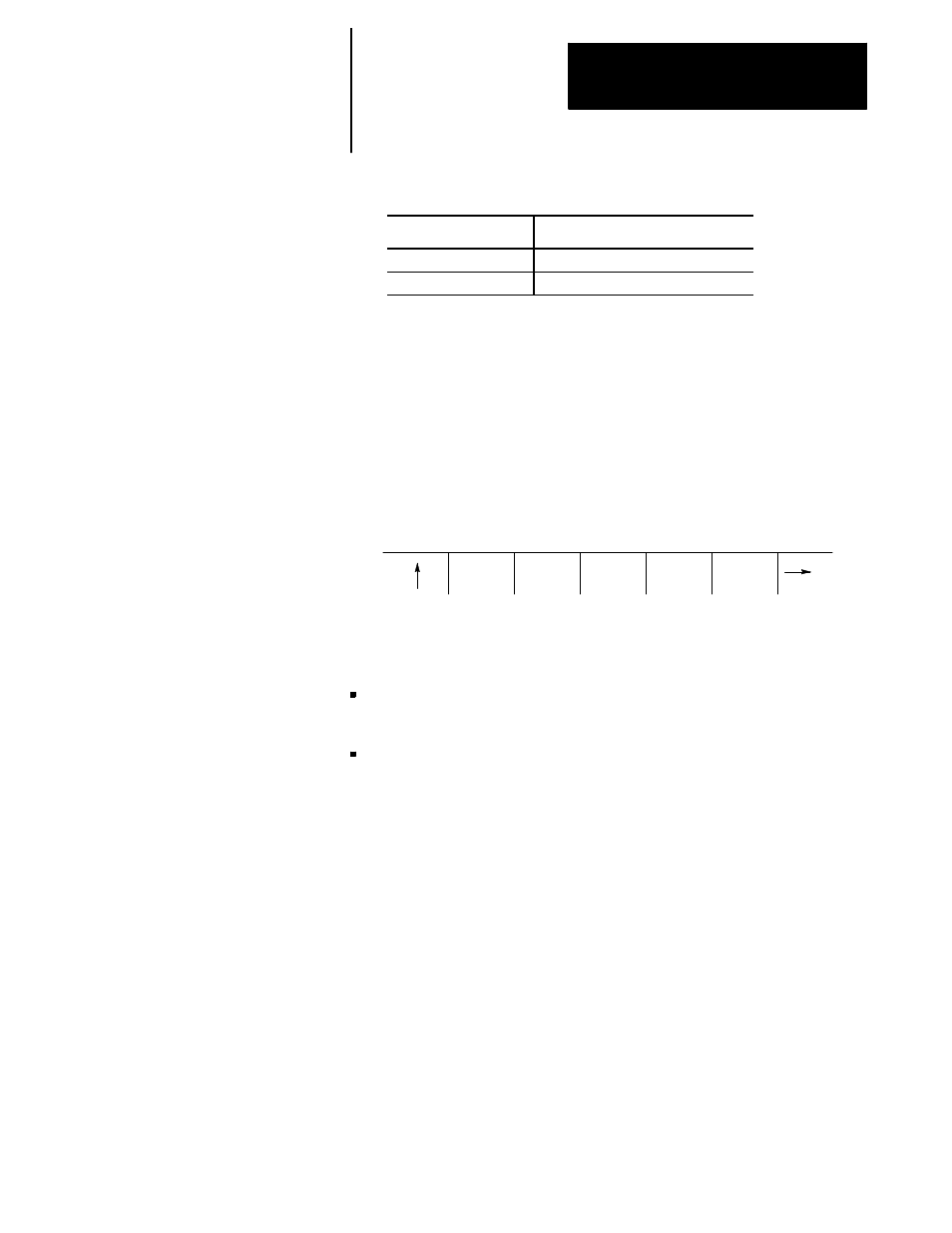

(softkey level 3)

SEARCH

NUMBER

REPLCE

VALUE

ADD TO

VALUE

ACTIVE

OFFSET

MORE

OFFSET

There are two types of data in the work coordinate system table. They are:

the initial work coordinate system zero point locations that are called

when programming G54 - G59.3.

the external offset which is used to offset all of the G54 - G59.3 zero

points to make the same set of work coordinate systems fit a variety of

applications.

Zero Point Parameters

The zero point parameters refer to the zero point locations of all of the

work coordinate systems called out by G54 - G59.3. Enter positions for

these zero points as machine coordinate values. The control uses the

specified machine coordinate position as the work coordinate system zero

point. Refer to chapter 11 for details on work coordinate system.

Enter a machine coordinate system position for each axis of the work

coordinate system below the corresponding G-code (G54-G59.3) as

described on page 3-16.

3.3

Work Coordinate System

Offset Table

{WORK CO- ORD}