Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 739

Program Interrupt

Chapter 29

29-9

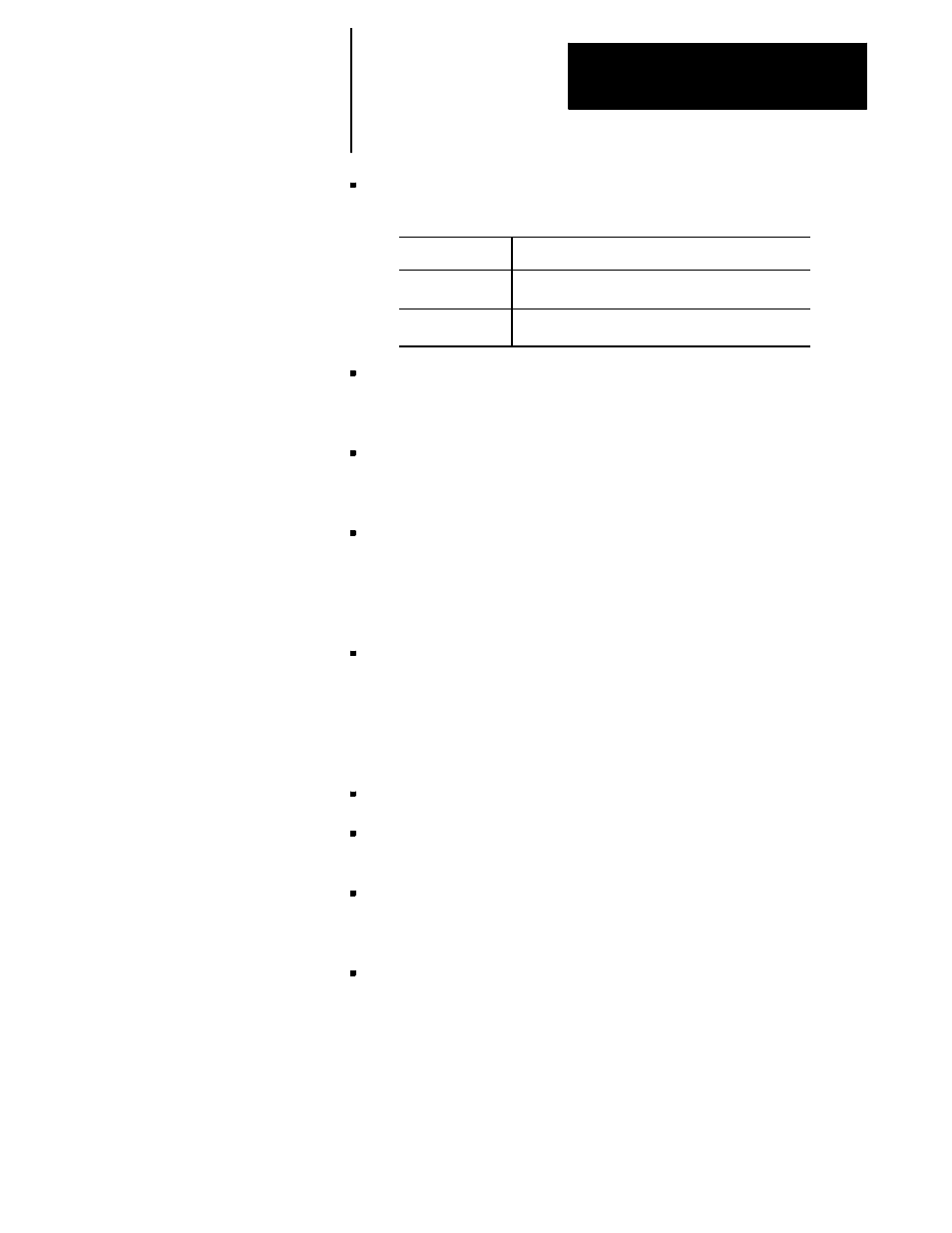

The system installer determines if an interrupt program is to be called as

a paramacro or a subprogram when it executes.

If it is Called:

Then:

A Paramacro

This assigns a new set of local parameters for the

interrupt

A Subprogram

The same set of local parameters that applied to the

interrupted program apply to the subprogram.

If an interrupt is chosen as a macro program, it may not be a macro that

requires the assignment of local variables in the calling block (cannot

require an argument).

Macro type interrupts are always called as the G65 non-modal type.

G66 and G66.1 modal types may not be called. Refer to the chapter on

paramacros for details on the G65 type macros.

The interrupt program must contain an M99 block. Any axis motion

commands that are to the left of the M99 code in the block will result as

an error. Other programming commands to the left of the M99 code in

the block will be executed. Any characters to the right of the M99 code

in the block are ignored.

If using a type 2 interrupt (L1, L2, or L3), remember that the control

remembers as many as the first 4 blocks in the program and uses these

to retrace its moves back to the starting point of the interrupt program.

The control remembers as many as 4 of the first moves or until a

circular block is executed. For details, see section 29.3 on interrupt

types.

The interrupt program may contain a milling cycle in the interrupt.

Coordinate system offsets are illegal in an interrupt program. This

includes G52, G92, G92.1, and G92.2.

Any inherent modality from the main program (such as a milling cycle,

or an active modal paramacro) will be temporarily canceled during the

execution of a interrupt program.

Although all four interrupts can be active at once, only one interrupt can

be executing at any given time.

END OF CHAPTER