Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 837

Error and System Messages

Appendix B

B-37

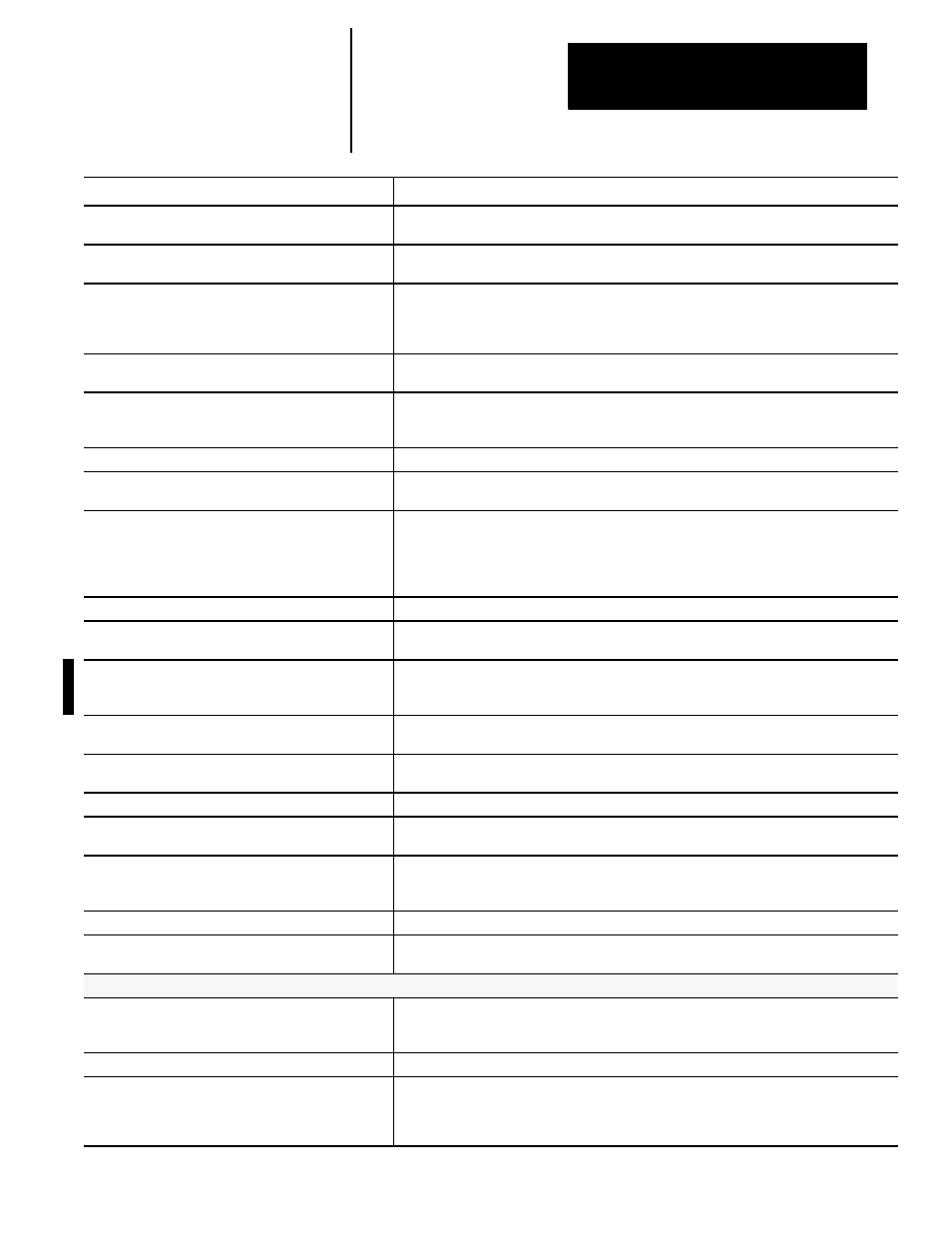

Message

Description

REMOTE I/O USER FAULT OCCURRED

The RIO module detected that the user fault bit was set. The interboard communications fault

LED is flashing.

REMOTE I/O WATCHDOG TIMEOUT

The watchdog mechanism on the RIO module timed out, indicating that the RIO module has not

operated in an expected manner for possibly 17ms. The processor fault LED is turned ON.

REMOTE IO INTERPROCESSOR HANDSHAKE FAULT

The RIO module failed to detect the complement of the user-handshake word, in the

complement user-handshake word in common RAM, within the handshake interval. The user

device has not shook hands with the RIO module. The interboard communications fault LED is

flashing.

REPLACE ABSOLUTE FB BATTERY

The battery that attaches to the servo module and supplies power for the absolute encoders is

under-voltage and must be replaced.

REPLACE MEMORY BACKUP BATTERY

The battery that attaches to the main processor board and supplies power for the control’s RAM

memory is under-voltage and must be replaced. If not replaced, AMP data cannot be copied to

backup memory and part program data may be lost.

REQUESTED DATA TOO LARGE

The data you are trying to send or receive is too large.

REQUIRES AT LEAST TWO AXES

A transfer line quick view prompt was selected for a cycle which requires two or more axes.

Your system is currently configured as a single axis system.

RESETTING E--STOP

Once you push the E--Stop Reset button to clear the E--Stop state, the Resetting E--Stop

message displays to alert you that the control is attempting to come out of E--Stop. After the

system is out of E--Stop and the drives are enabled, the control clears this message. If the error

condition is not cleared, this message clears, but the “E--STOP”message continues to flash as

the control remains in E--Stop state.

RETRACE NOT ALLOWED

A retrace is not allowed from the point in program execution.

RIGHT OPERAND MUST BE POSITIVE

The right operand of a logical operator must be a positive value. Negative values are illegal; for

example, 1AND--2 is illegal because of the --2.

RING I/O RECOVERY DISABLED

This message is activated when the {RECVRY DISABL} softkey is pressed on the I/O RING

MONITOR page. It is a visual indicator that the operator has disabled the I/O Ring retry

functionality.

RIO COMMON RAM ACCESS NOT ACKNOWLEDGED

The control’s request to use the RIO module was denied. The RIO module lost power, or the

control was restarted, but the RIO module was not.

ROLLOVER/OVERTRAVEL INCOMPATIBLE

Overtravel limits were specified in AMP for an axis that is configured as a rollover axis. Rollover

axes do not have overtravel limits.

ROTARY AXIS CANNOT BE SCALED

A rotary axis cannot be scaled.

ROTARY WORD OUT OF RANGE

A rotary axis was programmed to move to an absolute position that is greater than or equal to

360 degrees. In absolute mode, a rotary word must range between 0 and 360 degrees.

ROUGHING CYCLE NESTING ERROR

The contour blocks called by a roughing cycle to define the finished contour of a part contain a

block that likewise calls for a roughing cycle. Contour blocks for a roughing cycle cannot contain

a block that likewise calls for a roughing cycle.

ROUGHING CYCLE PROGRAMMING ERROR

A syntax error has been found in a roughing routine block (G72, G73, G74, or G75).

RUNG NUMBER NOT FOUND

The rung number you are searching for in the search monitor utility does not exist in the current

module, or does not exist in the program in the direction you are searching.

S

S--CURVE ACC/DEC CONFIGURATION ERROR

An axis configuration error was detected by the control when the programmed acc/dec ramp

was out of range. An attempt to program an acceleration ramp value of 0 in a G48.3 or G48.4

block. An attempt was made to program another G--code in a block with a G48.x.

S--CURVE MIN PROG JERK TOO SMALL

An attempt was made to select a jerk value below the allowable AMPed value.

S--CURVE MODE NOT ALLOWED

This message displays when an attempt was made to use a feature that is illegal in S--Curve

Acc/Dec mode. The following can not be used with S--Curve Acc/Dec: 7300 Series Tape

Compatibility, PAL Axis Mover, Circular Interpolation Mode (G02, G03), Feed to Hard Stop

(G24), jogging, threading, and solid tapping.