4 manual machine homing – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 101

Manual/MDI Operation Modes

Chapter 4

4-9

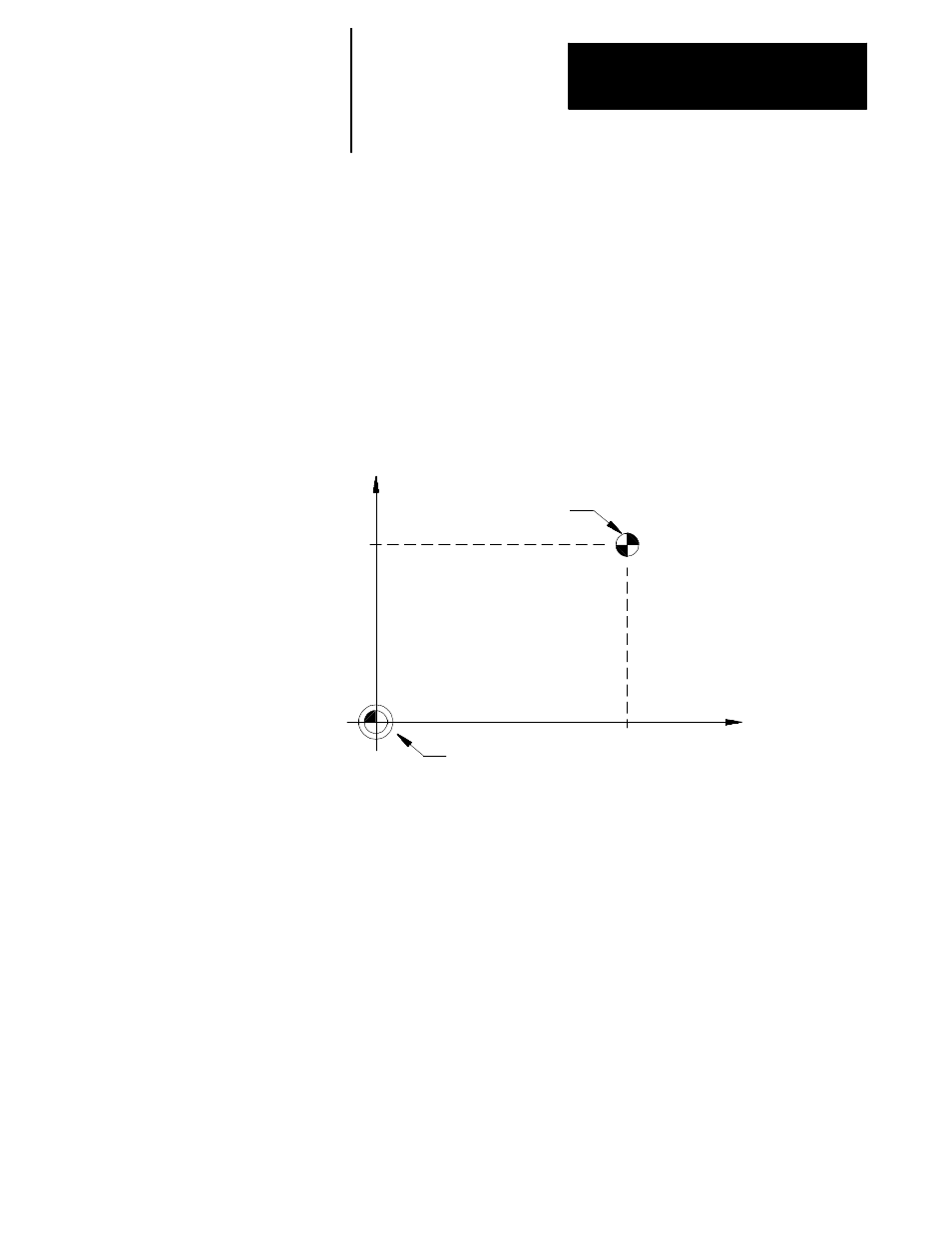

The machine home return operation means the positioning of a specified

linear or rotary axis to a machine-dependent fixed position, which is called

the machine home. This position is established via a home limit switch

mounted on the machine and the encoder marker.

The execution of machine home establishes the machine coordinate

system. Since all of the AMP-assigned work coordinate systems and all of

the programmable zones are referenced from the zero point of the machine

coordinate system, none of these features are available until the machine

homing operation has been conducted. Homing the axis should be the first

operation done on the control after power-up.

Figure 4.3

Machine Home

Machine coordinate

system zero point

+Z

+X

Machine

home

point

A

B

AMP-defined home

coordinates

X = A

Z = B

The following procedure describes how the control is homed manually by

using the pushbuttons on the MTB panel. Manual homing may be

different for some machines depending on the PAL program written by

your system installer.

Important: When a homing request is made the feedback device for the

axis (typically an encoder) must encounter at least one marker before

tripping the homing limit switch. If the axis is close to the home limit

switch you should jog the axis away from this switch before attempting a

homing operation.

Important: Automatic homing is available. Refer to page 14-12.

4.4

Manual Machine Homing