Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 577

Compound Turning Routines

Chapter 24

24-13

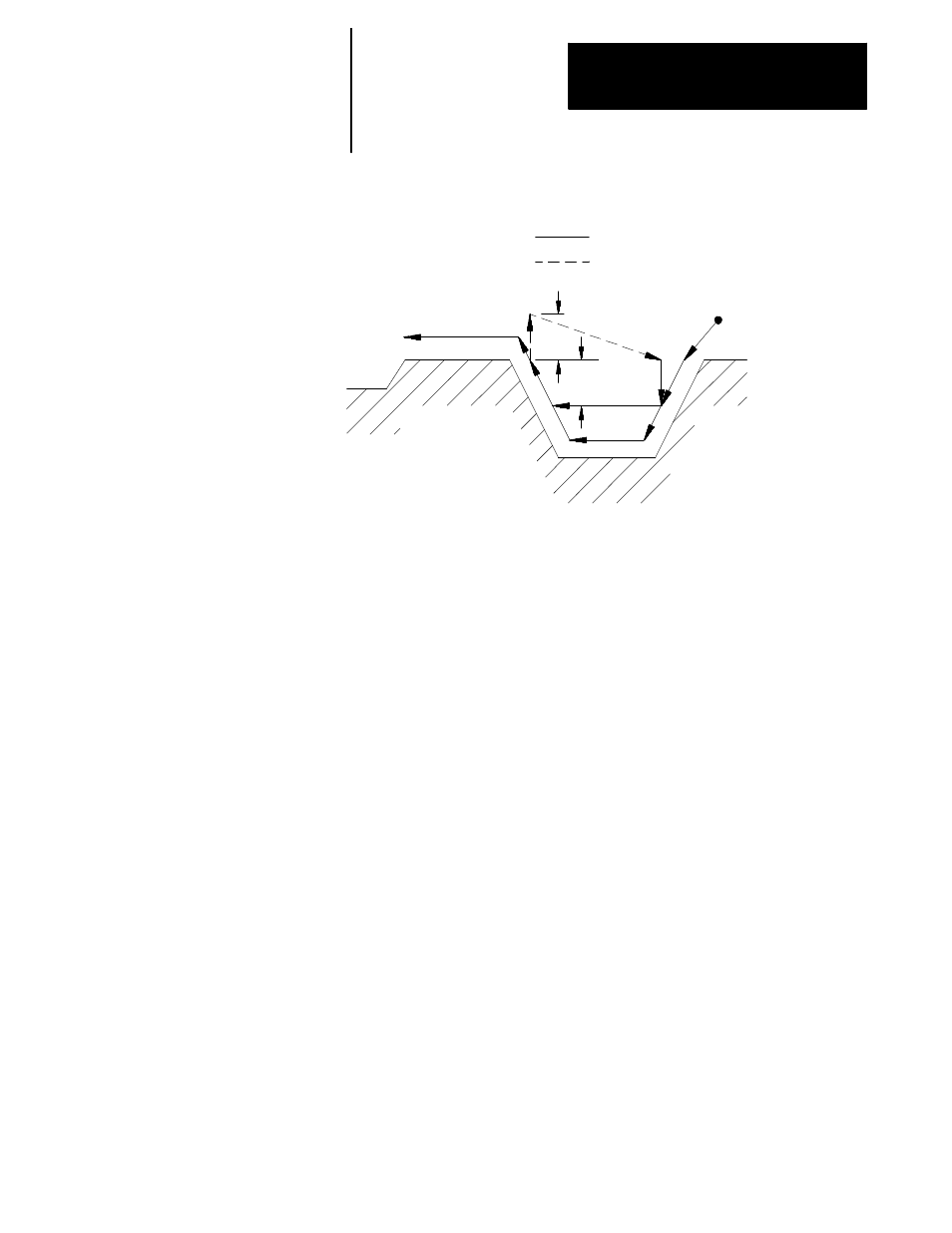

Figure 24.10

Tool Motion in Case 2 G73

Cutting feed

Rapid feed

Start point

1

8

R

D

8

8

8

6

7

4

3

5

2

In Figure 24.10, these tool paths are made:

1.

The tool is moved from the start point to first contour point at

feedrate F. This move must generate motion in both the X and Z

axes.

2.

The control generates a rough cut towards the spindle centerline,

parallel to the workpiece contour, and offset by the finish allowance

amount and the final pass amount (if any). This rough cut continues

until the X axis value has decreased an amount D as programmed in

the G73 block.

3.

A rough cut is made parallel to the Z axis, at a feedrate F, to a point

that intersects with the workpiece contour path minus the finish

allowance and final pass allowance (if any).

4.

A rough cut is made away from the spindle’s centerline, parallel to

the workpiece contour, and offset by the finish allowance amount and

the final pass amount (if any). This rough cut continues, at a feedrate

F, until the X axis value has increased an amount D as programmed

in the G73 block (or until the last contour point is reached).

5.

The tool is retracted from this point, on the X axis only, a distance R

as programmed in the G73 block (or the default distance R set in

AMP) at a feedrate F (see Figure 24.10)

6.

A rapid traverse is made back along the X and Z axes to the Z

coordinate that the last rough cut started from (in step 3) and an X

coordinate that is D distance above the X coordinate of the last

rough cut.