3 programmable zone 2 – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 333

Chapter 12

Overtravels and Programmable Zones

12-5

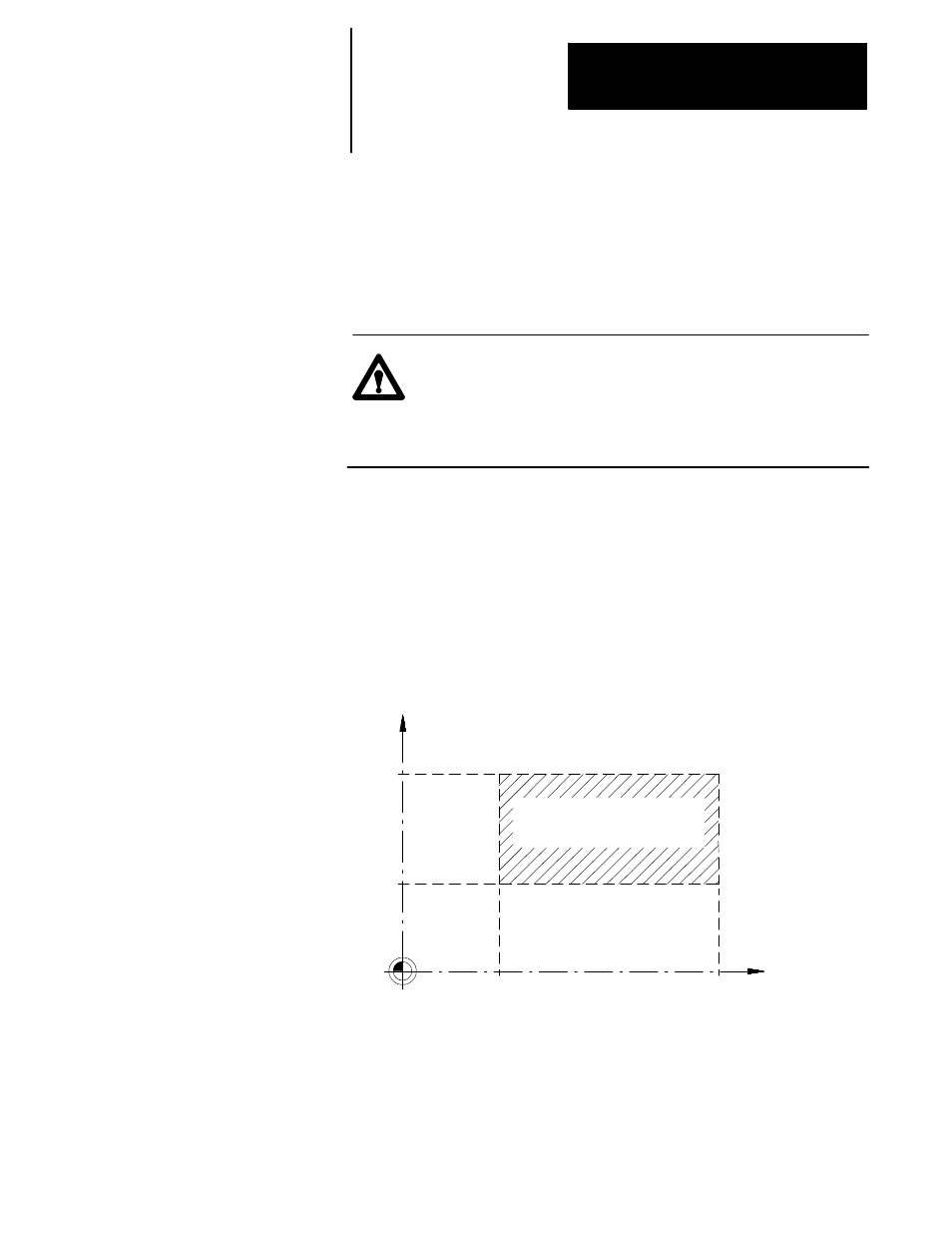

Programmable zone 2 defines an area which the tool cannot enter.

Generally, zones are used to protect some vital area of the machine or part

located within the software overtravels.

Important: Programmable zones are defined using coordinates in the

machine coordinate system. They are not affected by any changes in the

work coordinate system, including external offsets.

WARNING: Programmable zones only protect the tool tip

from entering the zone (as determined with the currently active

tool length offset). They do not protect other moving members

from collision with objects in the programmable zone’s

boundary.

Values for programmable zone 2 are entered in the programmable zone

tables as described on page NO TAG. These values represent a maximum

and a minimum value in the form of machine coordinate values for each

axis. The area defined by these points establishes the boundaries for

programmable zone 2.

Figure 12.4

Area Defining Programmable Zone 2

Programmable Zone 2

as defined by minimum

and maximum axis values

Machine

coordinate

zero

Min Z

value

Max Z

value

Z

X

Min X

value

Max X

value

Important: When changing a tool offset or activating a programmable

zone 2, the current tool tip location must be outside of the area defined by

programmable zone 2.

12.3

Programmable Zone 2