2 positioning and hole machining axes – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 630

Drilling Cycles

Chapter 26

26-4

This section assumes that the programmer can determine the hole

machining axis using the plane select G-codes (G17, G18, G19). Refer to

the system installer’s documentation to make sure that a specific axis has

not been selected in AMP to be the hole machining axis.

G-codes G17, G18, or G19 determine the plane, the hole machining axis,

and the positioning axes. The two axes that define the selected plane are

used as positioning axes. The axis perpendicular to the plane is the hole

machining axis.

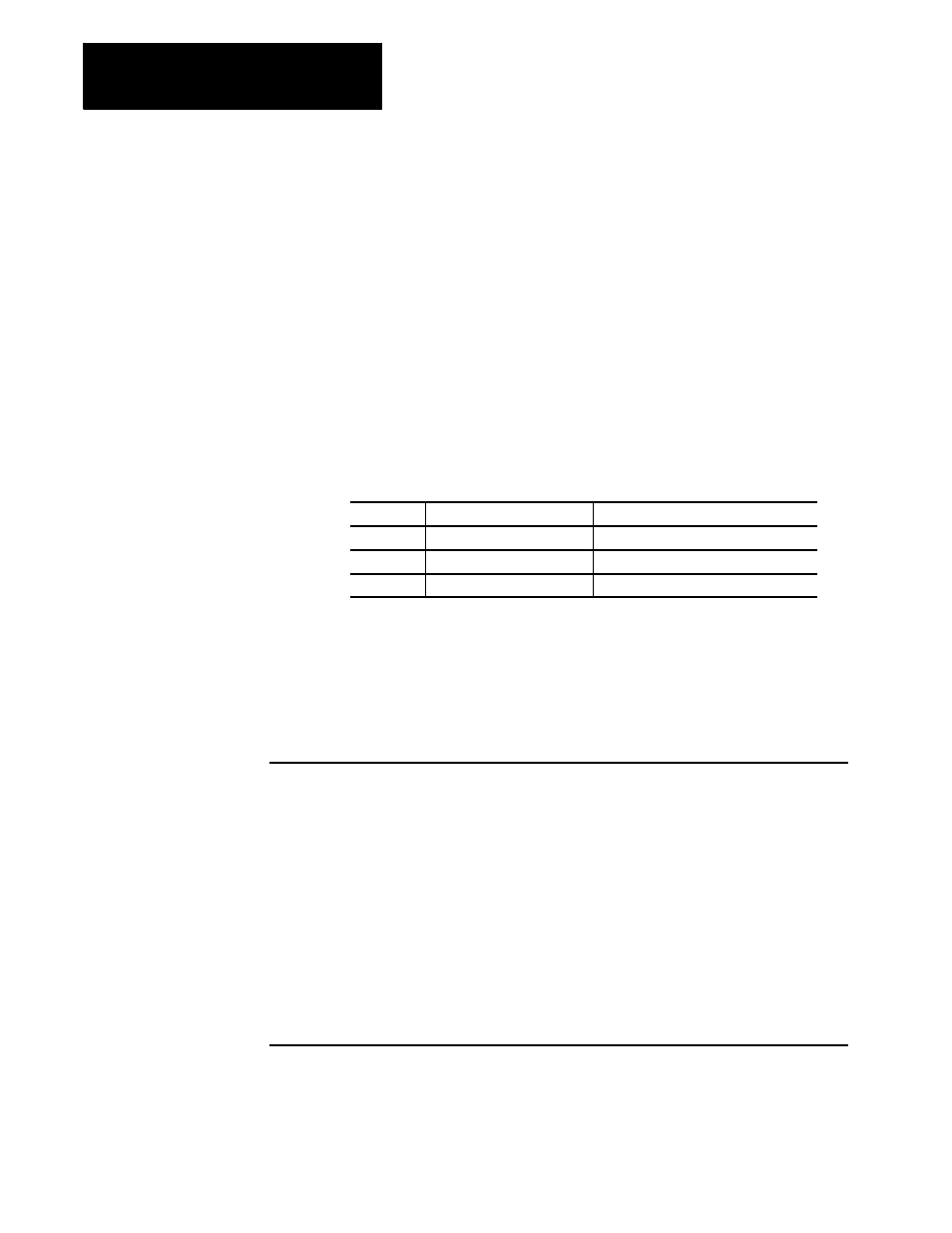

Table 26.B assumes a specific plane definition. Refer to the system

installer’s documentation for the plane definitions on your system.

Table 26.B

Plane Selection vs Machining Axis

Plane

Hole Machining Axis

Positioning Axes

XU (G17)

Z axis or its parallel axis

X and U axes or their parallel axes

ZX (G18)

U axis or its parallel axis

Z and X axes or their parallel axes

UZ (G19)

X axis or its parallel axis

U and Z axes or their parallel axes

Example 27.1 shows you how to change the hole machining axis to a

parallel axis. Prior to changing the hole machining axis, a G80 should be

executed to cancel any active milling mode.

Example 27.1

Altering the Machining Axis to a Parallel Axis

Program Block

Comment

The W axis is parallel to the Z axis.

G17;

XU plane active

G81X ___ U ___ ;

Drilling cycle, Z is the hole

machining axis

.

.

G80;

Cancel drilling fixed cycle

mode

G81X ___ U ___ W ___;

Drilling cycle, W is the hole

machining axis

.

.

The plane selection codes (G17, G18, and G19) can be included in the

drilling fixed cycle block, or can be programmed in a previous block.

26.2

Positioning and Hole

Machining Axes