1 o.d. and i.d. roughing routine (g73) – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 566

Compounding Turning Routines

Chapter 24

24-2

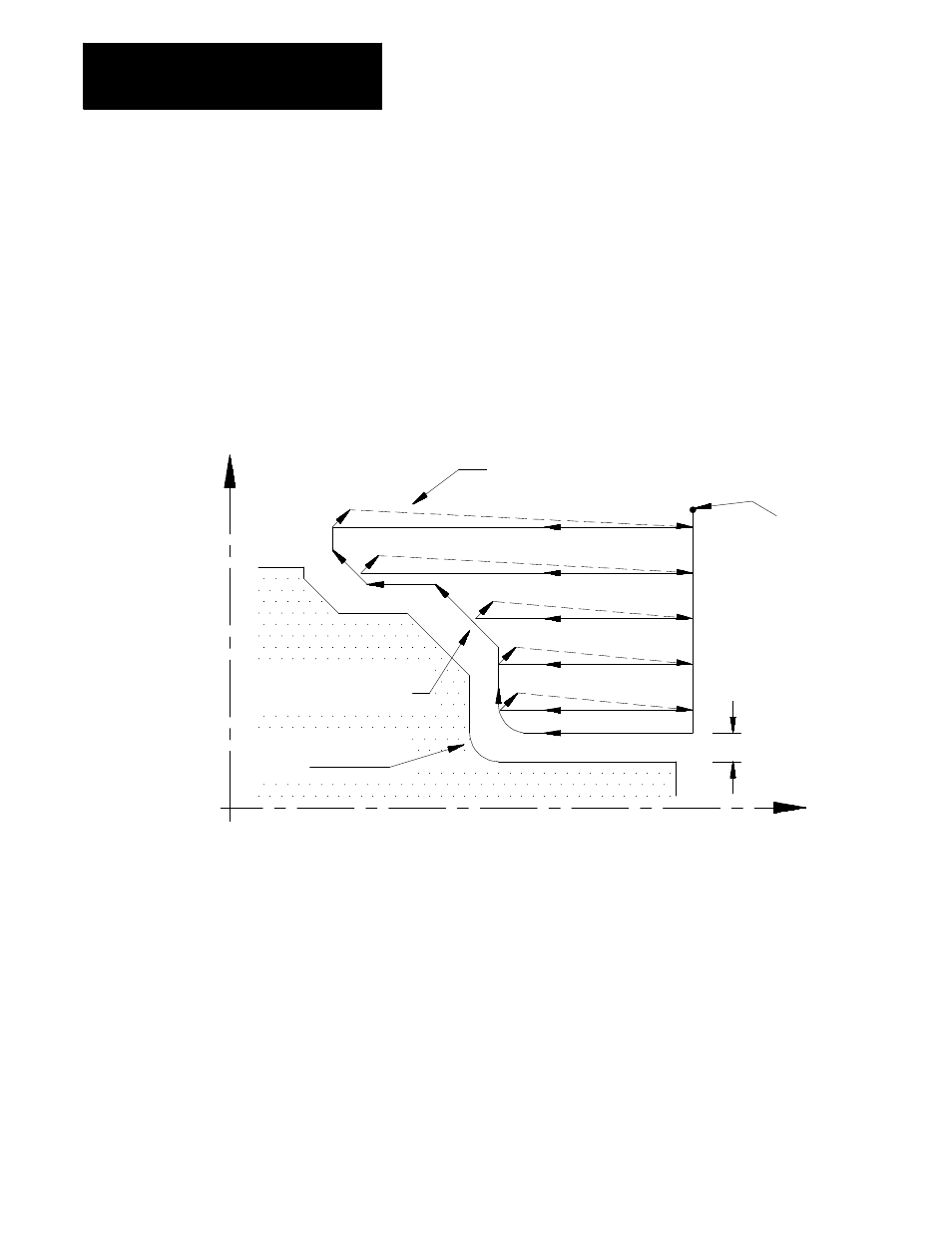

The G73 contour turning routine is used to rough out the contour of a

workpiece by making repetitive cuts parallel to the Z axis. A final pass

may be made with this routine to cut parallel to the final contour of the

workpiece. A finish allowance may be left on the workpiece to be

removed later by a G72 finishing routine.

This routine may be used in conjunction with Tool Tip Radius

Compensation (TTRC). If TTRC is active when the routine is executed,

the tool radius is taken into consideration on each consecutive pass.

Figure 24.1

Stock Removal in G73 Roughing Routine

Workpiece finished

shape

Shape after roughing

and final pass

Finishing allowance

Z

Start Point

Tool paths determined automatically

X

The G73 block has a P and a Q parameter that call out the sequence

numbers (N-words) of the first and last blocks defining the final contour to

be cut into the workpiece. This set of blocks may be located anywhere

after the calling block (even after an end of program command), as long as

the calling block is in the same program as the set of contour blocks. This

means that contour blocks can not be called from a subprogram or a macro

unless the calling block is in that subprogram or macro.

The control can handle two different cases of the G73 routine. It

automatically recognizes them and adapts the tool path accordingly.

24.1

O.D. and I.D. Roughing

Routine (G73)