Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 759

Chapter 30

Using a 9/Series Dual--Processing System

30-19

The Interference Checking feature is designed to help prevent collisions by

the axes of a dual-processing machine.

Interference checking provides an area (usually around the cutting tool or

tool turret for each process) that defines a boundary that moves with the

tool. The other process cannot enter into this boundary. This helps prevent

collisions.

For interference checking to function properly, you must define and

activate this boundary for both processes. When one process’s boundary

attempts to enter another process’s boundary, one process enters cycle

suspend, preventing it from entering the protected area. In the case of an

unavoidable direct collision, both processes stop. An error message is

displayed for both processes. The two boundaries cannot intersect.

CAUTION: These interference boundaries only help prevent

collision with another interference boundary configured for

another process. They do not protect against collisions with

other machine fixtures that may or may not be protected by a

programmable zone or software overtravel. They do not

account for any tool offsets that are active at the time. They are

absolute positions.

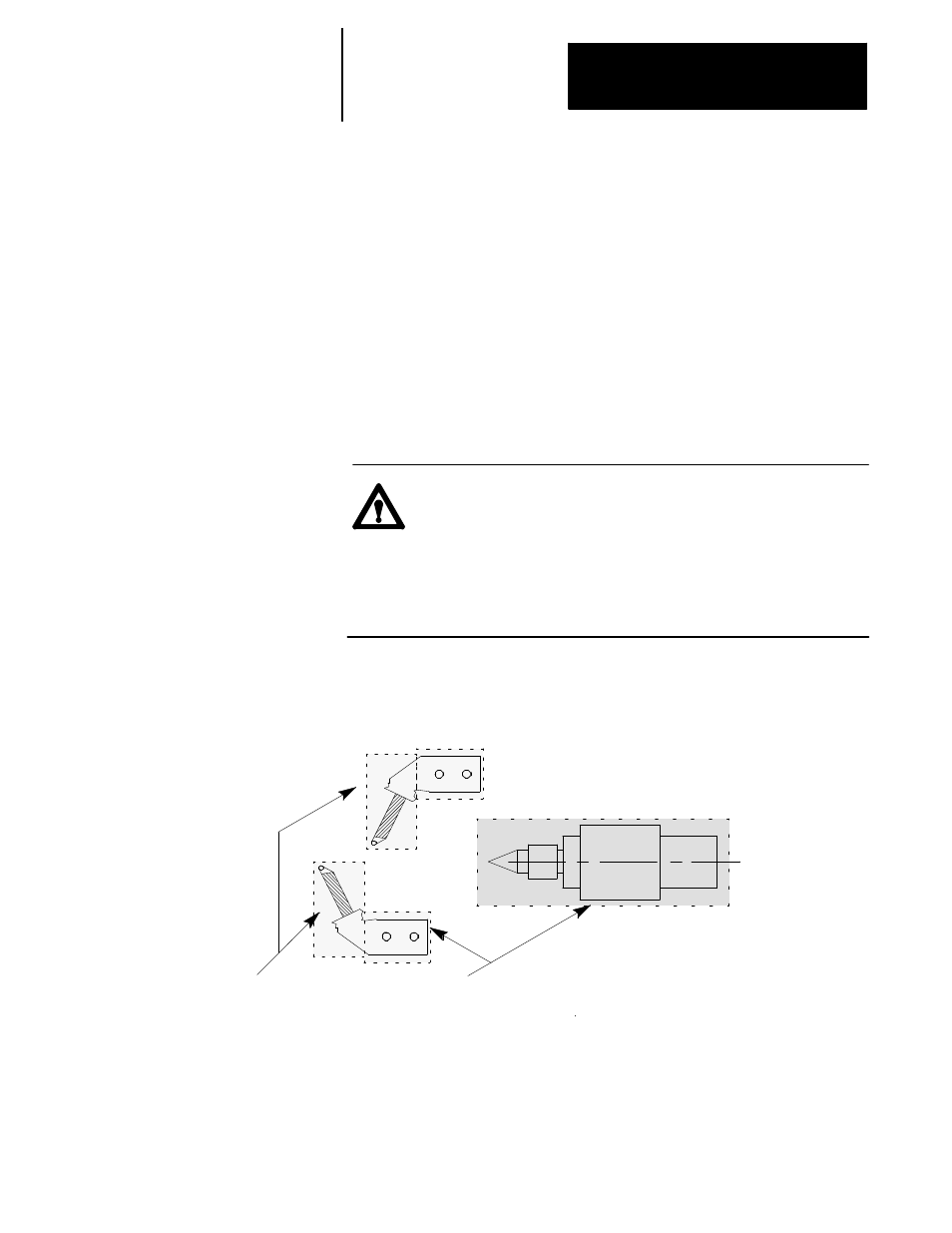

Figure 30.8

Interference Check Helps Prevent Tool Fixtures from Colliding

Programmable

Zone 1

Area protected against

collision by interference

checking. No collision

between these areas.

Interference checking does not protect programmable zones.

Only tool tip location is monitored for a programmable zone. Possible

collision between these areas.

Tailstock

12603-I

30.5

Using Interference Checking

with a Dual-Process Lathe