1 programming a t-word and tool offsets – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 459

Tool Control Functions

Chapter 20

20-3

Important: If tool life management is being used on the system, see the

tool management section in this chapter for details on programming a

T-word. This section assumes that the tool life management feature is not

being used.

Your system installer determines the format for a T-word in AMP.

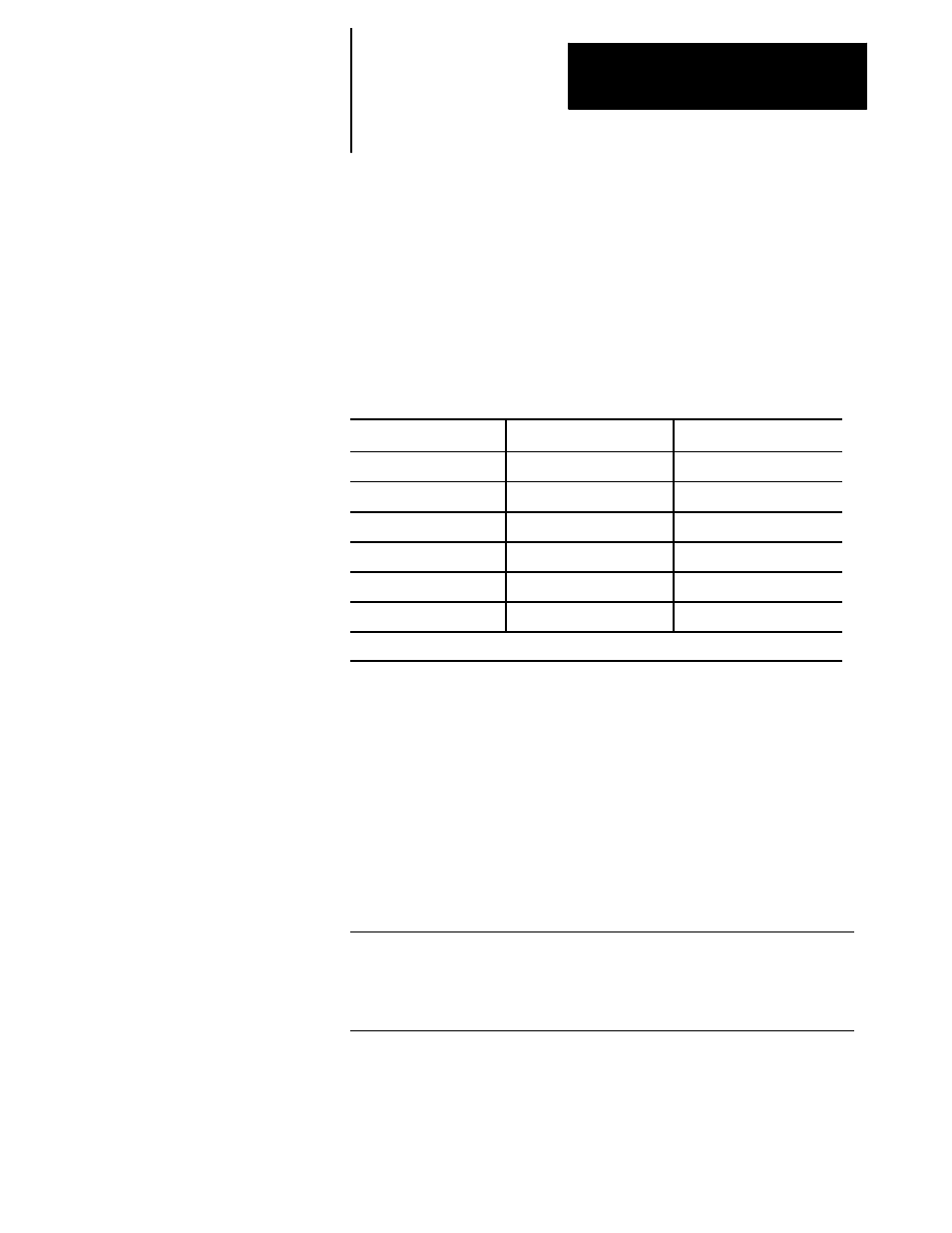

Table 20.A shows the 6 available format selections.

Table 20.A

T-word Formats

* FORMAT TYPE

WEAR OFFSET #

GEOMETRY OFFSET #

(1) 1 DGT GEOM + WEAR

last digit

same as wear

(2) 2 DGT GEOM + WEAR

last two digits

same as wear #

(3) 3 DGT GEOM + WEAR

last three digits

same as wear #

(4) 1 DGT WEAR

last digit

same as tool #

(5) 2 DGT WEAR

last two digits

same as tool #

(6) 3 DGT WEAR

last three digits

same as tool #

*

For details on which format is being used on a specific control refer to documentation prepared by the system installer.

To use Table 20.A find the format being used on your system. Then go

down the wear offset # column and find which digits of the T-word are

used as the wear offset number. Any other digits to the left of the wear

number are used as the tool number. If there are no digits remaining to the

left of the wear number, the control uses tool number 0. The third column,

geometry offset #, tells if the geometry number is the same number as the

number used for wear or tool. Just because geometry may use the same

offset number as wear it is not necessarily calling the same offset value.

Example 20.1

Using T-word Format #5

T213;

This T-word first calls for tool number 2 to be rotated into position, then data is accessed from

the offset tables (chapter 3) for values under tool geometry offset number 2, and tool wear offset

number 13.

20.1.1

Programming a T-word and

Tool Offsets