Important – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 34

Basic Control Operation

Chapter 2

2-12

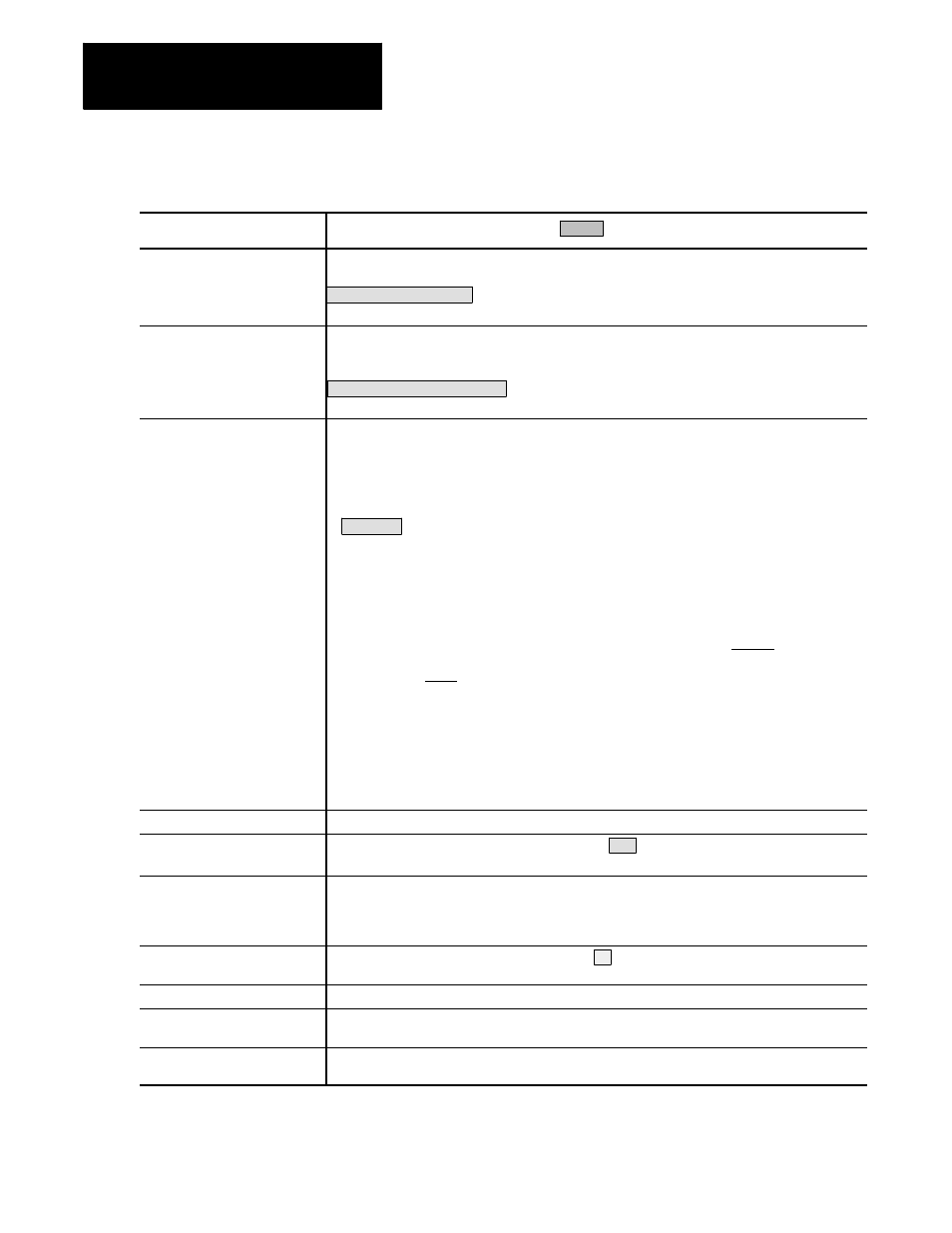

Table 2.D

Functions of the Buttons on the Push-Button MTB Panel

Switch or Button Name

How It Works

= Default for Push-Button MTB Panel

MODE SELECT

Selects the operation mode

AUTO ---- automatic mode

MANUAL ---- manual mode

MDI ---- manual data input mode

JOG SELECT

Selects the jog method to be active in manual mode

HANDWHEEL ---- HPG (hand pulse generator) jog

INCREMENTAL ---- incremental jog

CONTINUOUS ---- continuous jog

HOME ---- machine home

SPEED/MULTIPLY

Selects an axis feedrate or axis feed amount multiplication ratio used in the manual mode. Each

selection modifies the active feedrate by a value set in AMP. Modification also depends on the setting

of

·HANDWHEEL

When in handwheel jog mode, SPEED/MULTIPLY alters the handwheel resolution by a factor

determined in AMP. Your system installer sets the value for:

- LOW X1

- MEDL X10

- MEDL X100

You cannot use the values listed below for handwheel jog:

- MEDH X1000

- HIGH X10000

·INCREMENTAL

When in incremental jog mode, SPEED/MULTIPLY alters the incremental jog distance by a factor set

in AMP by your system installer. Your system installer sets a value for the selections. The

incremental jog speed is fixed to medium but can still be controlled by

.

·CONTINUOUS

When in continuous jog mode, SPEED/MULTIPLY acts as a feedrate selection switch which has

values set in AMP by your system installer. Your system installer sets a value for all 5 selections

independently for each axis.

Important:

The values for the different

your system installer.

SPINDLE SPEED OVERRIDE

Selects the override for programmed spindle speeds in 5% increments within a range of 50% to 120%.

SPINDLE or

SPINDLE DIRECTION

Selects spindle rotation, clockwise (CW), spindle stop (OFF), counterclockwise (CCW). Can be

overridden by any programmed spindle direction command.

FEEDRATE OVERRIDE

Selects a feedrate override percentage for the feedrate programmed with an F word in any of the

feedrates modes (G93/G94/G95) and the reciprocation feedrate programmed with an E word.

has a range of 0% to 150% of the programmed feedrate and alters the

programmed feedrate in 10% increments. When set to 0%, the control is effectively in feedhold.

RAPID FEEDRATE OVERRIDE

Selects the override for rapid feedrates. Select from F1, 25%, 50%, and 100% where F1 is a rapid

feedrate override setting established in AMP by the system installer.

EMERGENCY STOP

This button stops machine operation and disables the spindle and axis drives when pressed.

E-STOP RESET

This button resets an emergency stop condition when pressed. Before pressing this button the

condition that caused the E-Stop should be resolved.

CYCLE START

The control begins or resumes part program execution, MDI program execution, or program check

when this button is pressed.