Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 407

Spindles

Chapter 17

17-9

In the G97 mode, the spindle revolves at the programmed RPM regardless

of the position of the cutting tool.

For example, to revolve the spindle at 500 rpm, program:

G97 S500 M03;

The G97 code is modal and remains active until it is cancelled by the G96

code.

Important: If an S-word is specified in the G97 block when you change

from G96 to G97 mode, the control uses the S-word as the new RPM

value. If no S-word is contained in the G97 block, the control uses the

current RPM of the tool as the programmed spindle RPM. The spindle

speed then remains at this constant RPM.

Use the G12 code to program the active controlling spindle for all

programmed axes motions for features and modes requiring spindle

operation. The G12 code is modal as only one spindle can be the

controlling spindle. All other spindles are auxiliary spindles.

G12.1 — Spindle 1 Controlling

G12.2 — Spindle 2 Controlling

G12.3 — Spindle 3 Controlling

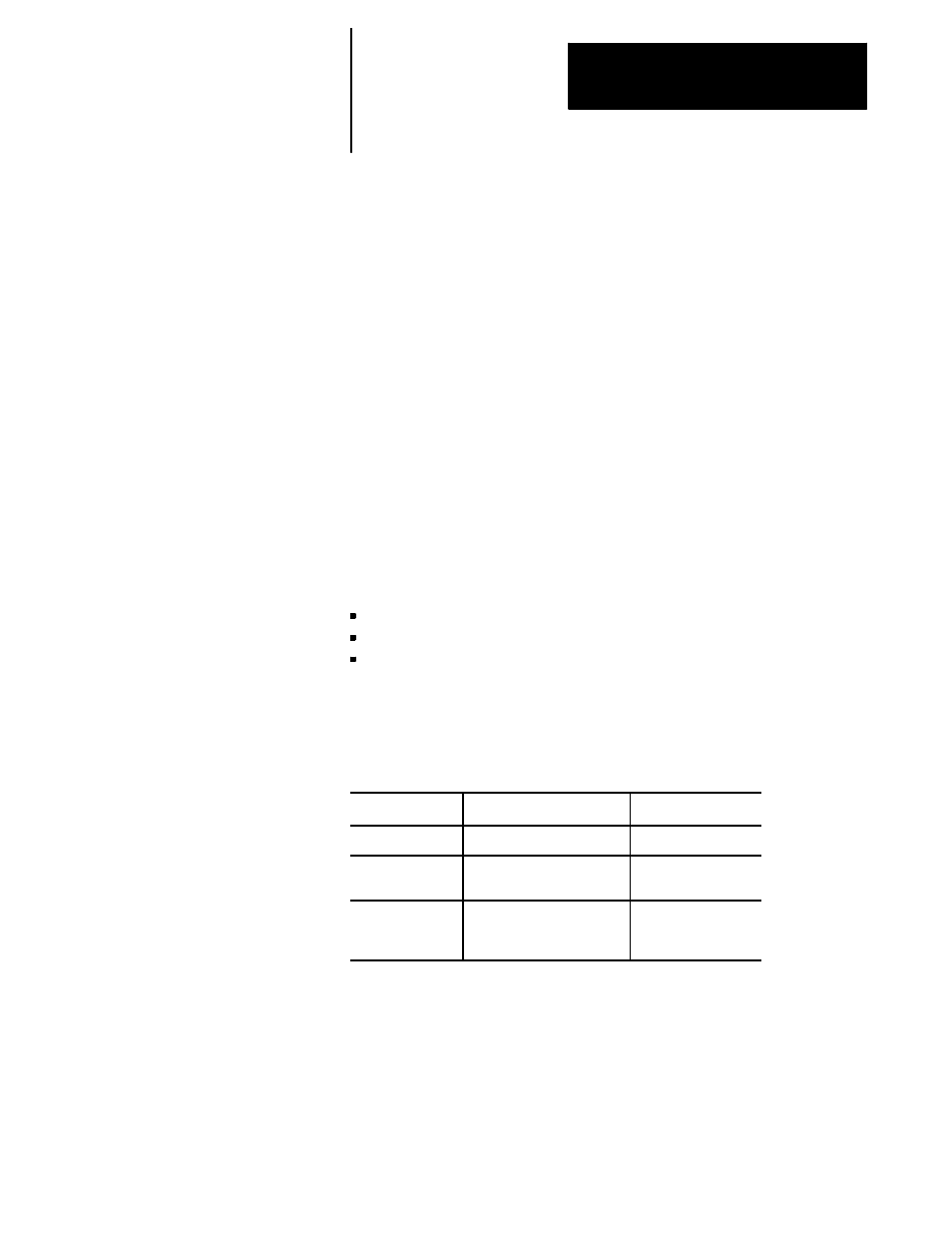

Table 17.B lists the allowed spindle capabilities.

Table 17.B

Spindle Capabilities

Control Type

Number of Spindles

Spindle Type

9/230 or 9/240

1

Primary

9/260

2

Primary

Auxiliary 2

9/290

3

Primary

Auxiliary 2

Auxiliary 3

The spindle 1, as well as spindle 2 and 3, must be configured in AMP, and

the associated spindle parameters must be set properly to provide for the

required spindle functions.

17.1.2

RPM Spindle Speed Mode

(G97)

17.2

Controlling Spindles

(G12.1, G12.2, G12.3)