3 synchronizing multiple part programs – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 747

Chapter 30

Using a 9/Series Dual--Processing System

30-7

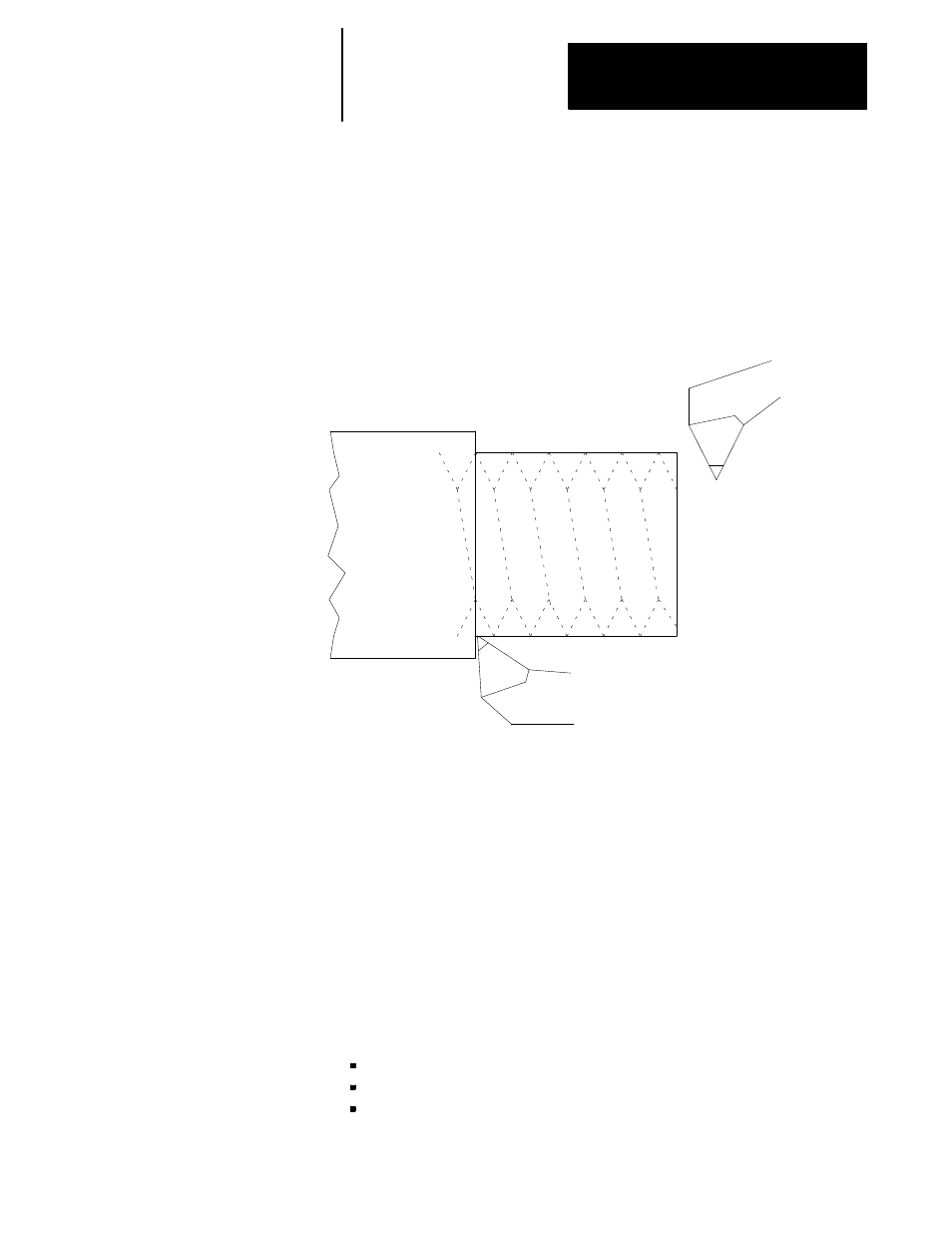

On some machines or systems, it is often necessary to synchronize the

operations of 9/Series dual processes. For example, on a dual-turret lathe,

if one turret must rough a shaft down to size before another turret begins

cutting a thread, it is extremely important that the turret roughing the shaft

completes this task before the threading turret begins cutting the thread.

Figure 30.3

Example of When Process Synchronization is Necessary

First process must rough down stock before second process can

start cutting threads.

Process 1

Roughing

Process 2

Threading

12598-I

Part program synchronization is accomplished between processes through

the use of special M-codes. These M-codes are in group 13, and they are

non-modal. The M-codes reserved for synchronization are M100 - M199.

When you execute a synchronization M-code in one process, that process

halts until a block containing the same synchronization M-code is executed

in the second process. In the case of the threading example on page 30-7,

placing one of these M-codes before the threading block and after the

roughing block causes the threading block to pause (not execute) until the

roughing block has completed.

These synchronization M-codes cannot be programmed in a block with

other commands. The only other types of information you can program in

a synchronization block are:

N-codes (block number)

O-words (program name)

Program comments (text enclosed by parentheses () )

30.3

Synchronizing Multiple Part

Programs