Programming multipass thread cutting – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 621

Thread Cutting

Chapter 25

25-21

Programming Multipass Thread Cutting

Before programming the G78 threading routine, the cutting tool must be

positioned to the point from which the routine is to be executed. This point

is the end-point of each complete cycle of the threading routine’s

execution.

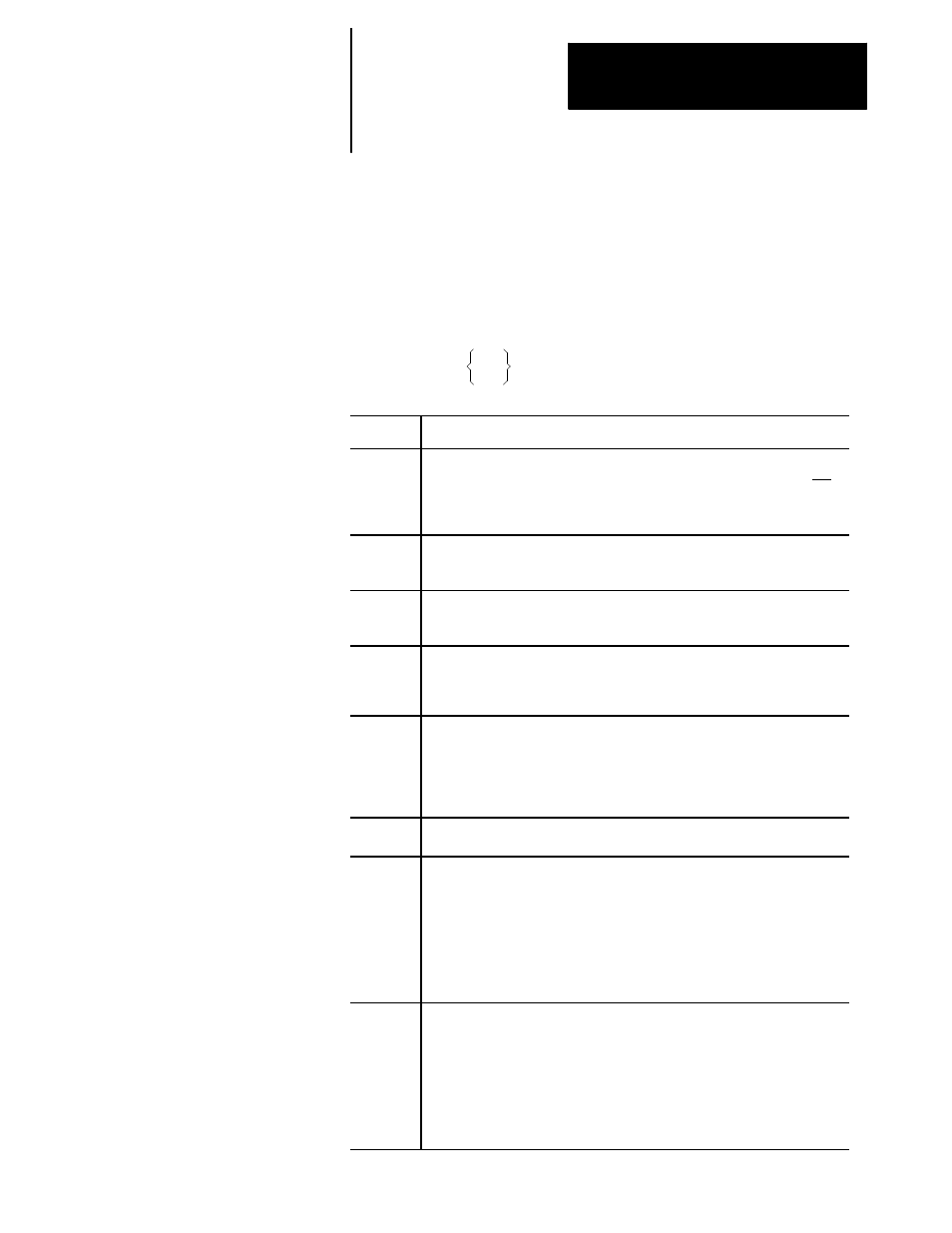

Use this format to program a multipass thread cutting routine:

G78X__Z__K__D__

F__

A__P__I__;

E

Where :

Is :

X:

This parameter is the coordinate value of the root (depth) of the thread. If

programming a tapered thread, it is the coordinate value to be attained at the end

of the last threading pass (assume there is no chamfer cut at the end of the

pass). X values may be entered as a radius or a diameter value. X may also be

programmed as an incremental or absolute value.

Z:

This parameter is the Z coordinate value of the end of the thread cutting pass. Z

parameters are always entered as a radius value regardless of the current mode.

Z may also be programmed as an incremental or absolute value.

K:

This parameter is an unsigned value (always programmed as positive). It

programs the distance from the thread root (as determined by the X parameter to

the top of the thread. K is always programmed as a radius value.

D:

This parameter programs the depth of cut (designated in radius) for the first pass.

It is an unsigned value (always programmed as positive). The depth of following

passes is determined by this value and the type of infeed selected with the P

parameter.

A:

This parameter programs the angle of the tool tip. It must be entered as an

integer value from 0 to 120 (corresponding to 0-120 degrees). Not programming

a value for A is the same as A0. A0 would be the same as a plunge type infeed.

The value entered here determines the angle that the infeed moves makes,

which also determines the final thread angle. See the tool infeed section that

follows for details.

P:

This parameter determines the tool infeed. It must be entered as an integer

value from one to four. See the tool infeed section that follows for details.

E,F:

This parameter may be entered by using either E or F for the thread lead

(as in G33).

If the E-word is programmed, its value (always unsigned) is equal to the number

of threads per inch or inches per thread (determined in AMP) regardless of

whether inch or metric mode is active at the time.

If the F-word is programmed, its value (always unsigned) is the thread lead in

inches per revolution or millimeters per revolution, depending on the mode in

which the control is operating.

I

This is the change in radius of the thread (on the X axis) that the threading pass

makes as it reaches the end-point of the thread cutting pass. The end-point is

the X position programmed with the X-word. I is an incremental, signed distance

(+ or -) added to the X parameter to determine the start-point of the threading

pass on the X axis. If a chamfer is being cut at the end of the thread cutting

pass, it does not affect the value programmed here. This parameter should be

entered as if no chamfer were being cut. I is always an incremental value

regardless of the current mode. This parameter is always entered as a radius

value regardless of the current mode.