The format for the g29 block is – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 855

Allen-Bradley 7300 Series CNC

Tape Compatibility

Appendix D

D-5

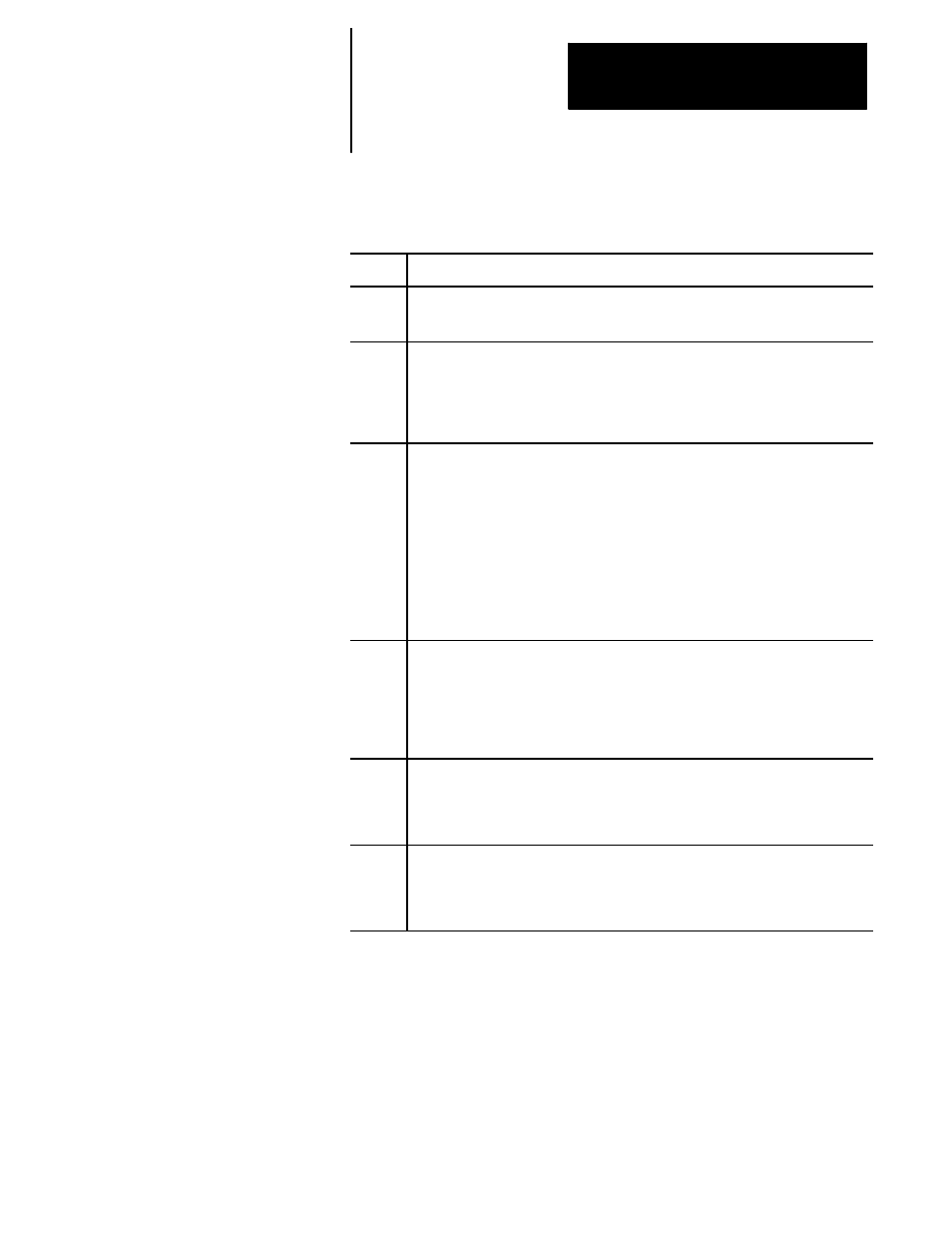

The format for the G29 block is:

G29__D__K__I__Z__L__F

Where: Specifies:

D

return pass clearance, which is the distance between the initial work surface and the

starting point. D value must always be programmed as an incremental distance,

regardless of the current operating mode.

K

thread lead, which is the distance the thread cutting tool is to move along the Z axis per

revolution of the spindle. The thread lead is always programmed in units of inches per

revolution (IPR) in the Inch format mode (G70), or millimeters per revolution (MMPR) in

the Metric format mode (G71).

Does not need to be programmed for roughing cycle.

I

thread lead for a tapered thread, which is the distance and direction the thread cutting

tool is to move along the X axis per revolution of the spindle. The thread lead is always

programmed in units of inches per revolution (IPR) in the Inch format mode (G70), or

millimeters per revolution (MMPR) in the Metric format mode (G71). The I-word

determines the angle of a tapered thread. If the angle is known, I-word can be

calculated with the following formulas:

I-word = K-word * Tan0

Assign a value to I only if cutting tapered threads (I

¹

0).

Length of the roughing pass for Z axis roughing cycle, I is the distance along the X axis.

Does not need to be programmed for single axis roughing.

Z

length of the thread. For Absolute Programming mode, the thread length is programmed

as the Z axis position of the end of the thread. For Incremental Programming mode, the

thread length is programmed as a distance measured parallel to the Z axis from the

infeed endpoint to the end of the thread.

Length of the roughing pass for roughing cycle, which is the distance measured parallel

to the Z axis.

L

pullout distance, which is the distance from the programmed end of the thread to the

point at which the thread cutting tool is to start pulling out from the workpiece. This

distance is measured parallel to the Z axis. If no L-word is programmed, then the tool

does not pull out until it reaches the programmed end of the thread. L-word must always

be programmed as an incremental distance, even in the Absolute Programming mode.

F

feedrate of the return path, which is the rate at which the tool moves away from the part

and returns to the start-point of the cycle for the next infeed. The infeed rate is always

programmed in units/inches per minute (IPM) in the Inch mode, or millimeters/minute

(MMPM) in the Metric mode. If no F-word is programmed in the G29 block, the last

programmed feedrate before the G28 block is used.