2 corner radius – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 394

Chamfering and Corner Radius

Chapter 16

16-4

Use the ,R command to program a radius between two intersecting tool

paths. The R command must be programmed after a comma (,). Program

the ,R followed by the radius size in the block where the first path is

programmed. The control looks ahead to the block commanding the

second path and automatically inserts the circular rounding bock to meet

that path. This inserted circular block is always tangent to both

programmed tool paths. If the control cannot generate an arc that is

tangent to both paths with the programmed ,R, then the control generates

an error.

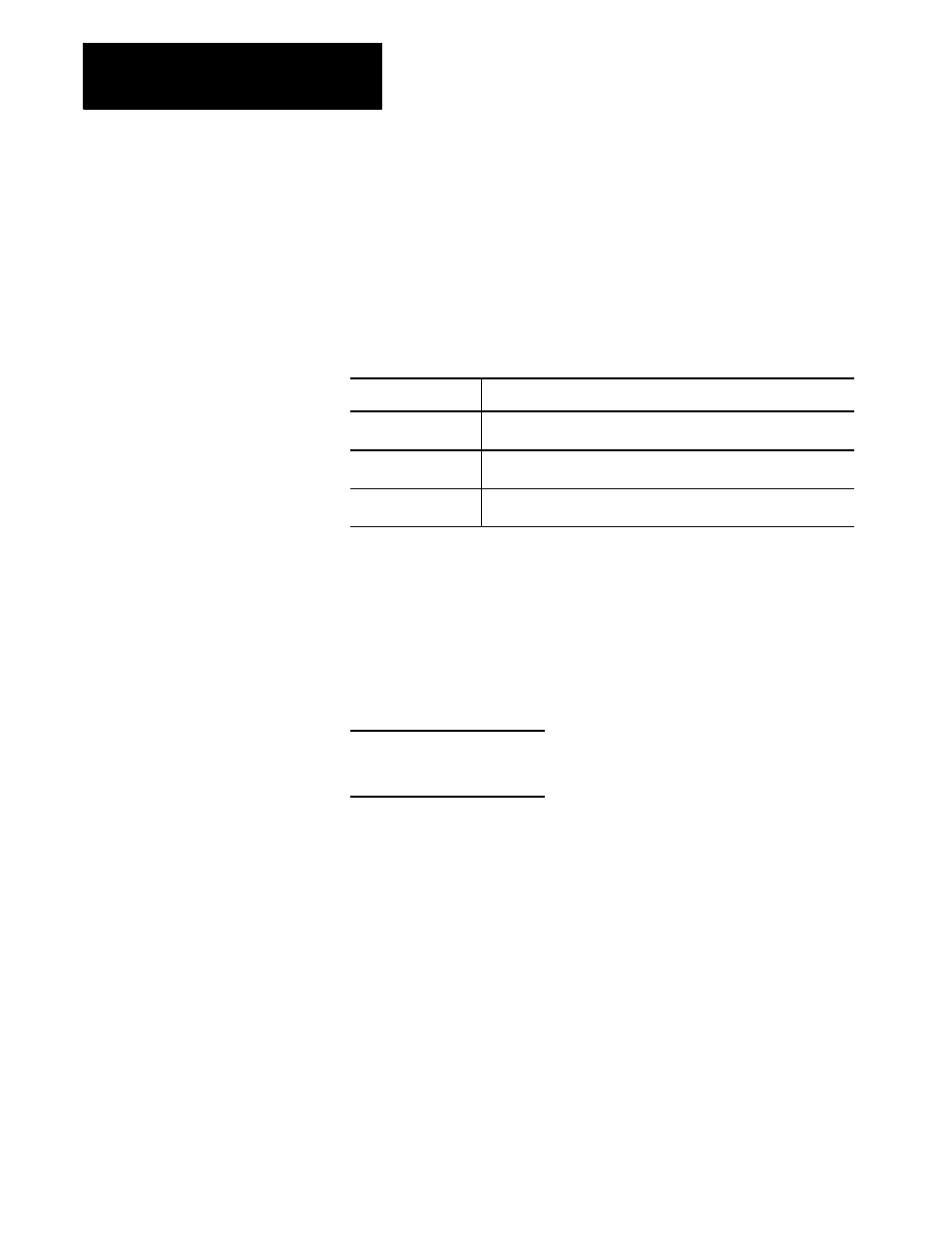

Block:

Description:

The first corner radius

always terminates at the point on the block where the rounding block

is tangent to the first block

The rounding

terminates at the point where the generated rounding block is tangent

to the second rounding block.

The second rounding

starts from the end point of the generated circular block and continues

on to the programmed end point of the second block.

The R-word can be programmed any where in a block as long as no space

is programmed between the ,R and the radius length.

Important: If the two motion blocks are tangent to each other, then any

corner rounding commands are ignored.

Example 16.3

Programming a Radius for a Circular Path into a Linear path.

N10Z10X30.F.1;

N20G02X10.Z10.R10,R3;

N30Z30.X10.;

16.2

Corner Radius