Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 512

Tool Tip Radius Compensation (TTRC)

Function

Chapter 21

21-28

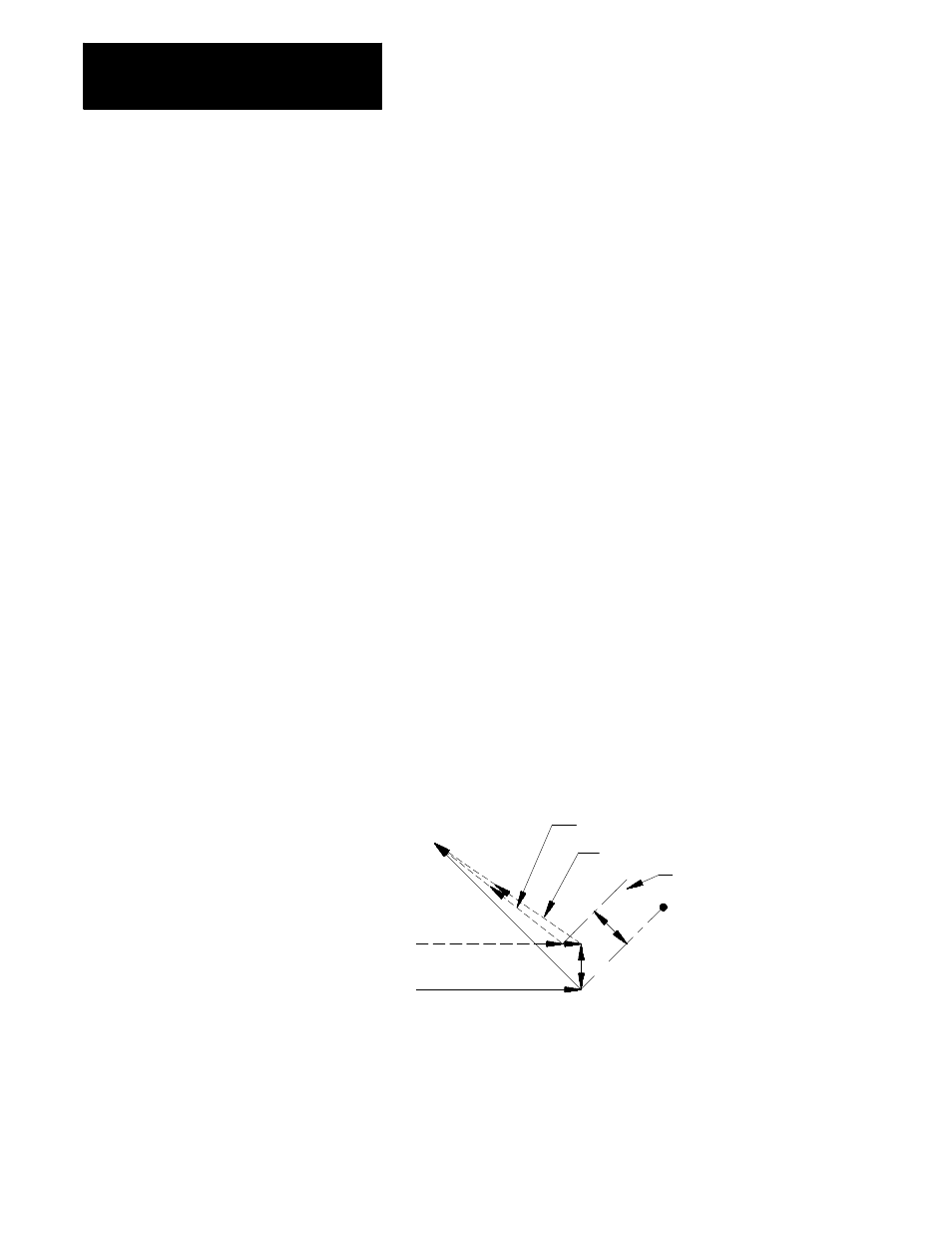

Figure 21.20 and Figure 21.21 assume that the number of blocks that do

not contain axes motion in the currently selected plane, following G40

before the exit move takes place, do not exceed an amount selected in

AMP by your system installer. If the number of non-motion blocks

following G40 exceeds the limit, the control generates its own exit move.

This may often cause overcutting of the part, since this move is a linear

path directly back to the programmed tool path.

You can modify the path that the tool takes for an exit move by including

an I- and/or K-word in the exit move. Only the I- or K-words that

represent values in the current plane are programmed in the block

containing the exit move. I and K correspond to the X and Z axis

respectively.

The I- and K-words in the exit move block define a vector that the control

uses to redefine the end-point of the previously compensated move.

The vector defined by the I- and/or K-words is along a line drawn from the

end-point of the programmed path through a point programmed with the I-

or K-words. The I- and/or K-words must be in the currently defined plane.

The point defined by I and K is always one incremental distance from the

end-point of the last move measured parallel to the X and Z axis.

A new vector is then defined parallel to the vector defined by the I- and/or

K-word and offset from this vector in the direction and amount of the

currently active offset (G41 or G42). The intersection of this new vector

with the current compensated tool path defines a point which is the new

end-point of the last programmed compensation move.

Figure 21.22

Exit Move Defined By An I, K Vector

Compensated path using I, K vector

Compensated path if no I, K in G40 block

Intercept line

I, K

Compensated path

Programmed path

r

r

Figure 21.22 is the exception. The change in length of the compensated

path is more than one radius of the tool. In this case, this offset is limited

to one radius of the tool. The direction of the offset is towards the point of

intersection of the I and/or K vector and the current compensated tool path.