Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 72

Offset Tables and Setup

Chapter 3

3-4

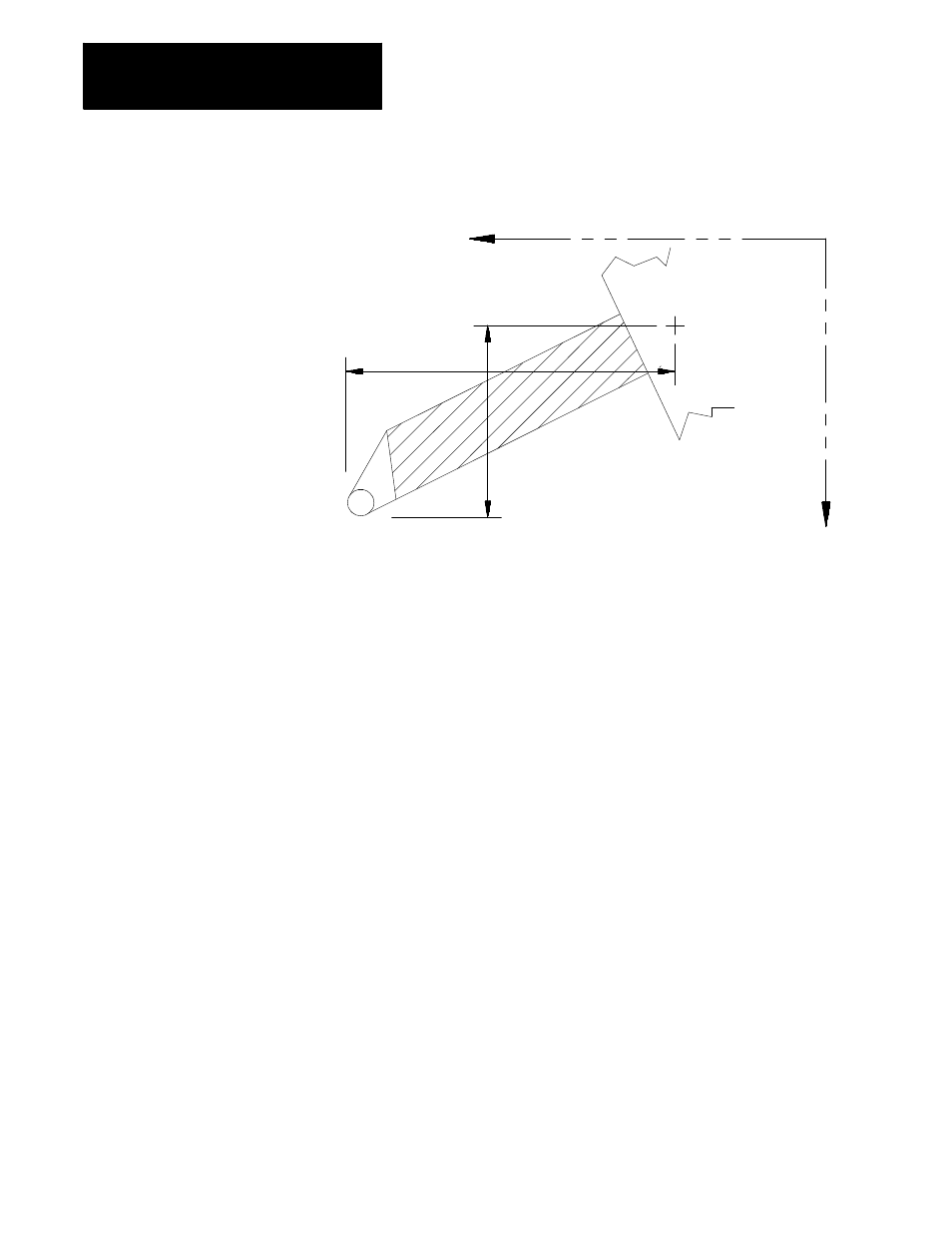

Figure 3.3

Tool Length Offsets

-Z

Z

tool offset

Gauge point

X

tool offset (entered

as a diameter value)

-X

The Z offset table value corresponds to the actual Z distance from the tool

tip to the gauge point. The X offset value is the distance on the axis from

the tool tip to the gauge point. Consequently, when the control activates a

tool offset, the Z axis is displaced per the table value, while the X axis is

displaced half the table value.

Generally machines are configured such that axes move in the negative

direction as they move the tool turret towards the workpiece (this refers to

the main or A turret if a two turret lathe). In that case, if the installed tool

protrudes in the negative direction its offset value is entered as positive.

The tool illustrated in Figure 3.3, for example, extends in both the -X and

-Z directions, so its X and Z offsets would be entered as positive. This

holds true regardless of which turret the tool is on.

Tool Tip Radius - TTR (Tool Geometry Table)

The control can compensate for any cutting error resulting from slight or

even large rounding of the cutting tool tip. To do so, the radius of the

cutting tool tip must be entered as the geometry data for tool tip radius

compensation. For more information, refer to chapter 21.