Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 768

Chapter 30

Using a 9/Series Dual--Processing System

30-28

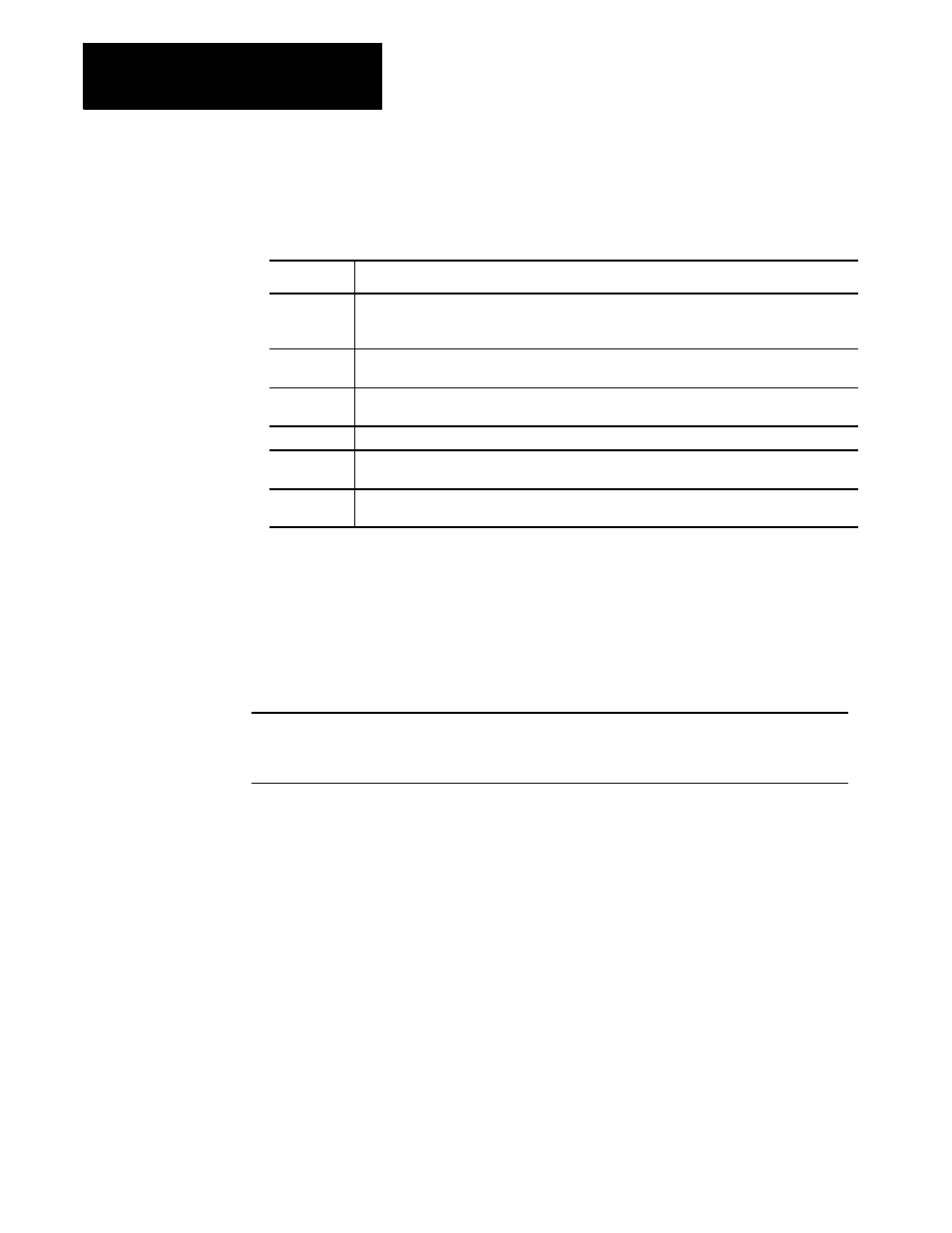

This is a representation of the basic format for modifying the tables.

G10 L

{ }

P__ X___ Z___ I___ K___;

5

6

Where :

Is :

L(5-6)

The definition of which area in the table is being modified.

L5 -

Modifies the Area 1 values

L6 -

Modifies the Area 2 values

P

The boundary number of the interference boundary that is having its values changed is

specified following the P address.

X

The value to add to (in G91 mode) or replace (in G90 mode) the positive X axis value. This

value is always a radius value.

Z

The value to add to (in G91 mode) or replace (in G90 mode) the positive Z axis value.

I

The value to add to (in G91 mode) or replace (in G90 mode) the negative X axis value. This

value is always a radius value. I is the integrand word of the X axis.

K

The value to add to (in G91 mode) or replace (in G90 mode) the negative Z axis value. K is the

integrand word of the Z axis.

Programming this G10 code can change only the table values for the

process that has the G10 part program currently active. You must run

separate G10 programs in each process to set up each area.

Important: G10 blocks cannot be programmed when TTRC is active.

Example 30.8

Using G10 to Change the Interference Boundaries

N1 G90 G70;

N2 G10 L5 P1 Z19.5 K13 X19 I15;

Boundary number 1 area 1 is defined.

N3 G10 L6 P1 Z23 K19.5 X18.5 I11;

Boundary number 1 area 2 is defined.