3 parameters – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 633

Drilling Cycles

Chapter 26

26-7

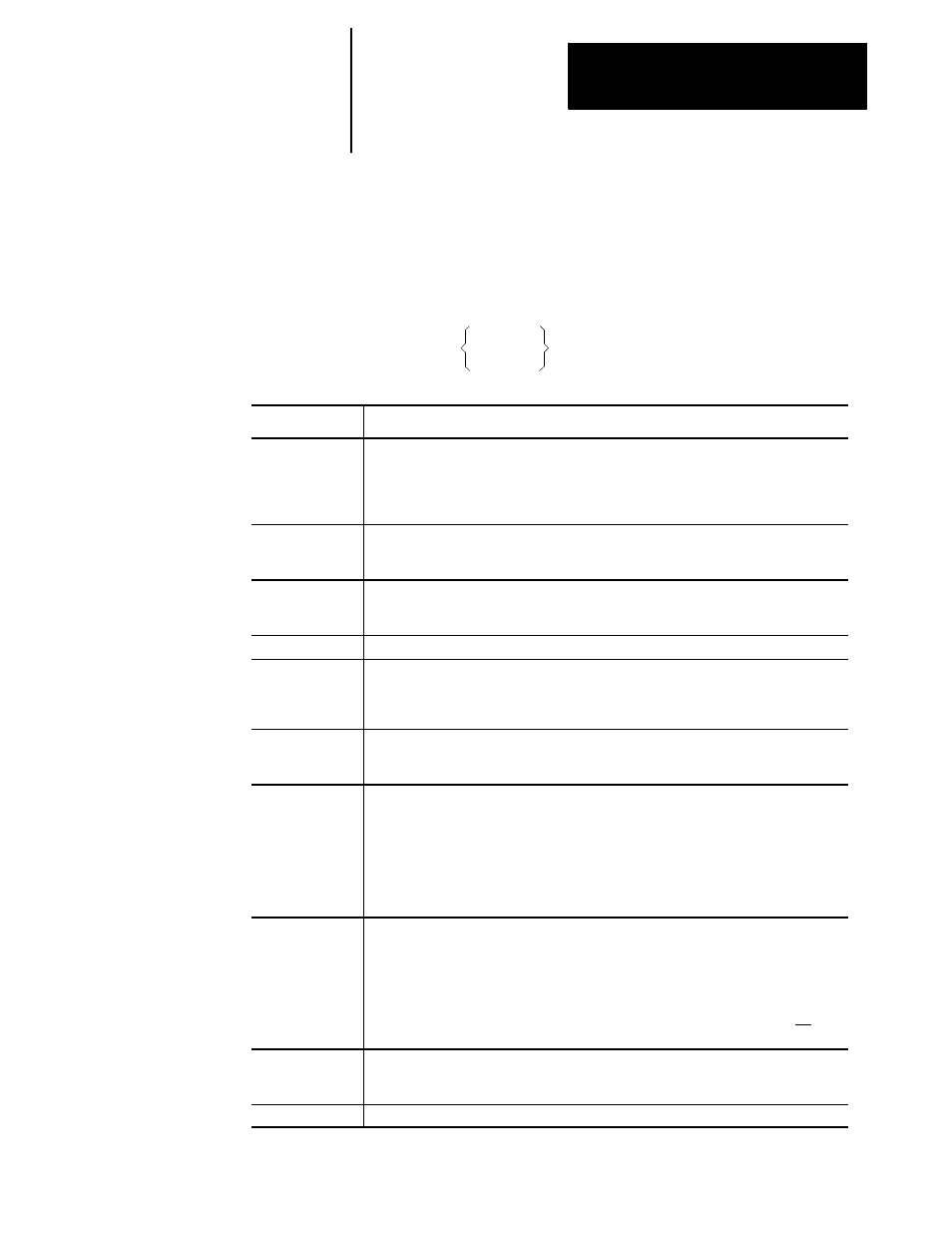

This section provides a detailed explanation of each parameter you can

program for the drilling cycles. Some parameters are not valid with all

cycles; see the specific description of each cycle. To alter drilling cycle

operation parameters, see section 26.5.

These drilling cycle parameters are described below:

X__Y__Z__R__

I__J__K__

P__F__L__Q__D__S__;

Where :

Is :

X

specifies the location of the hole position in the selected plane.

In the absolute mode

(G90), program the hole position using the coordinate values in the active coordinate

system. In incremental mode (G91), program the hole position using the distance from the

current tool position to the required hole position. This parameter is affected by radius or

diameter programming modes.

Z

defines the hole bottom.

In absolute mode (G90), program the hole bottom level using the

coordinate value in the active coordinate system. In the incremental mode (G91), program

the distance from the R point level to the hole bottom level.

R

defines the R point level.

In the absolute mode (G90), program the R point level as a

coordinate value in the active coordinate system. In the incremental mode (G91), program

the R point level by the distance from the initial point level to the R point level.

I, J, K

define the shift amount

for G86.1 and G87.

P

defines the dwell period at hole bottom.

P programs the dwell in the same way as G04:

seconds if in feedrate mode (G94), spindle revolutions if in revolution mode (G95). (The

allowable dwell time range in seconds is 0.001-99999.99. The allowable dwell range in

revolutions is also 0.001-99999.999.) The P-word does not apply in all drilling cycles.

F

defines the cutting feedrate.

If this parameter is not specified, the control uses the

currently active feedrate for the cutting feedrate. For G84.2 and G84.3, F = tap thread lead

in inches/mm per revolution.

L

defines the number of times the drilling cycle is repeated.

The maximum number of

repeats is 9999.

· In absolute mode, the control drills in the same location the number of times specified by

the L-word.

· In incremental mode, the L-word drills the number of holes specified by the L-word at

equally spaced positions, determined by axis positioning parameters X and Y.

· If an L0 is programmed, the control decodes the milling cycle information, but does not

execute the drilling cycle. If no L-word is programmed, the control defaults to L1.

Q

In G83, Q defines the infeed amount for each move made in the hole.

In G86.1 and G87, Q defines the shift amount (as do I, J, and K).

In G84.2 and G84.3, Q defines the angle at which to orient the spindle before starting the

tap. If you don’t program the Q-word, the spindle is not oriented before the tap begins. This

means that the hole is not retappable unless a Q-word is programmed in the cycle block.

The spindle is brought to a stop prior to the initiation of the tapping phase even if Q is not

programmed; this happens after the move to the R-plane.

D

defines the return spindle speed

so that, if you want, the tap-out move can be performed

faster or slower than the tap-in. Tool selection by D-word is not possible while in the

solid-tapping mode.

S

defines spindle speed in rpm.

26.3

Parameters