Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 70

Offset Tables and Setup

Chapter 3

3-2

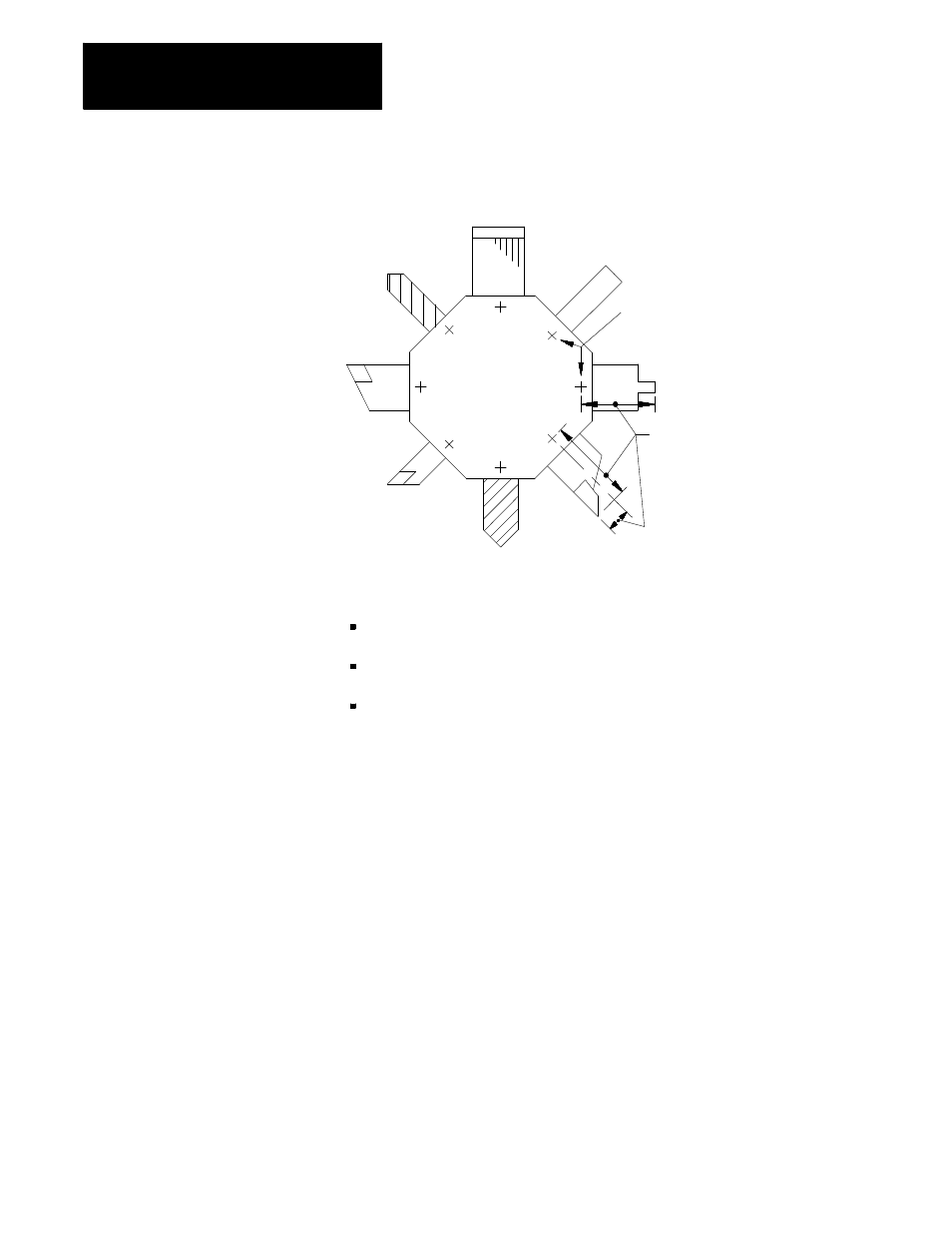

Figure 3.1

Tool Offset

Tool gauge points on turret

from which tool offsets are

usually measured

Tool offset values simplify

programming and allow

processing with different

tools without changing

the part program

You can enter this data into the tool offset tables:

Tool length offset data

{TOOL GEOMET}

and

{TOOL WEAR}

Tool tip radius data

{TOOL GEOMET}

and

{TOOL WEAR}

Tool orientation data

{TOOL GEOMET}

Parameters for the resolution of the offset data are determined by the

system installer in AMP. The range available to the system installer is 0.01

to 0.00001 mm (0.001 to 0.000001 inch) with a maximum number of 8

digits.

Tool Offset Numbers

Use a T-word to call out tool offset numbers in a program. The T-word

specifies a one, two, or three-digit offset number. The control then

accesses the values assigned to that offset number in the table. Offsets are

activated as described in the sections on that specific type of offset.

For more information on calling offset numbers, refer to chapter 20.

Offset number “00” is not valid, but can be used to cancel tool offsets.

Different offset numbers may be called from the tool geometry and tool

wear table using the same T-word (depending on the T-word type selected

in AMP). This means that wear offset data corresponding to offset number

1 may not need to correspond to tool geometry offset number 1, etc.