Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 483

Tool Control Functions

Chapter 20

20-27

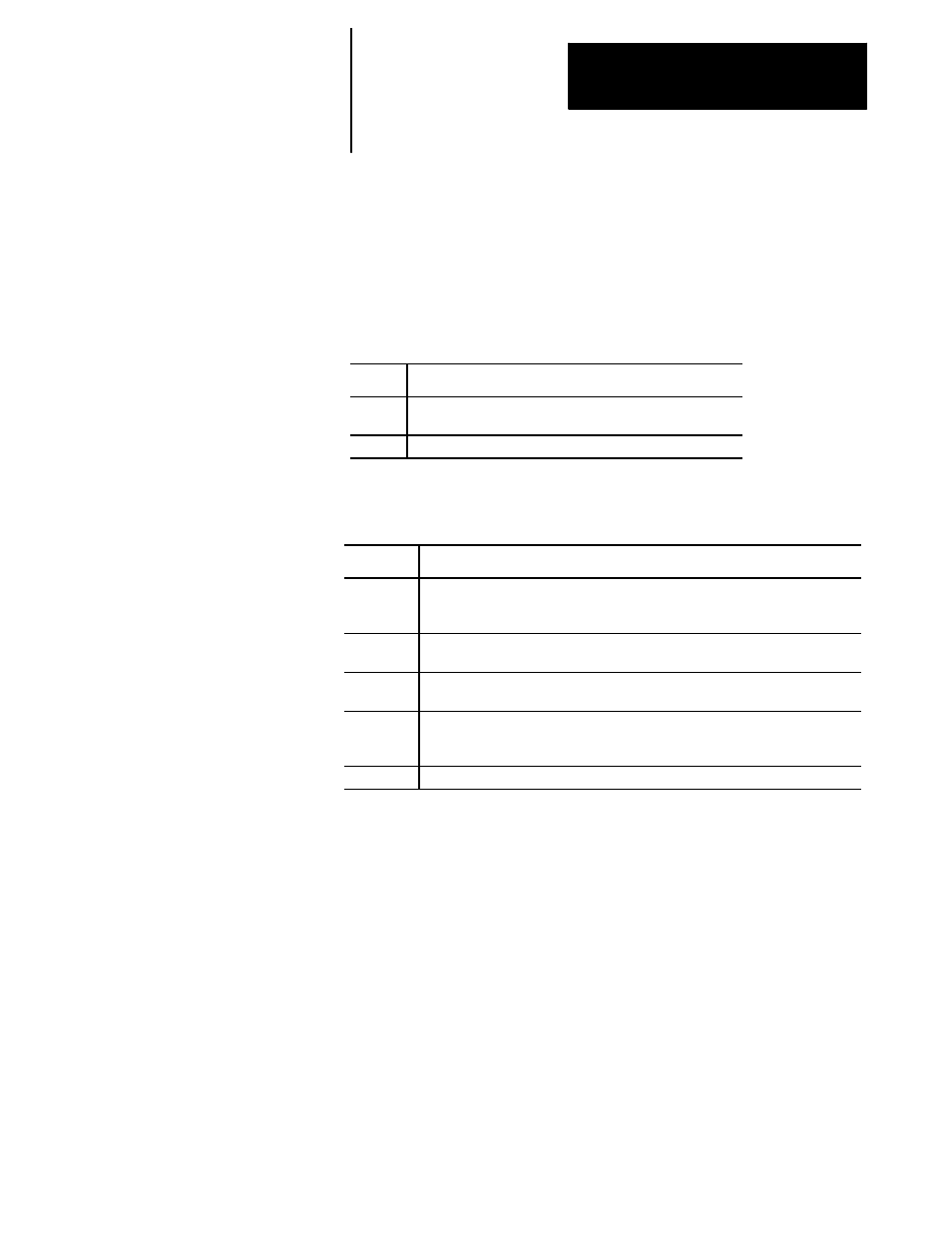

Example 20.7

Assume your system installer has set the following constraints in AMP:

- the tool group boundary is set as 100

- the T-word format is configured as 2-digit geometry and wear (see

section 20.1)

- the maximum allowable T-word is configured as a 5-digit number

To use tool management program for these constraints:

Ttttoo;

Where : Is :

Tttt

---- the group number (if greater than the group boundary)

---- a tool number (if less than the group boundary)

oo

the place holder for the tool offset number

Table 20.B

Result of Different T-words for Example 20.7

T-word

Result

T12;

Since tool number is below boundary and two digits are necessary for offset with

this T-word format, no tool is programmed here. Instead tool geometry and tool

wear offset number 12 is selected.

T1201;

Tool 12 and geometry and wear offset number 1 is selected. Tool life management

is not used because tool number 12 is below the group boundary of 100.

T10100;

The first available tool assigned to group 1 is selected along with the offset numbers

assigned to that tool in the tool management table.

T10201;

The first available tool assigned to group 2 is selected along with the offset numbers

assigned to that tool in the tool management table. The geometry and wear offset

number of 01 programmed here is ignored.

T123456;

Error occurs because maximum allowable T-word of 5 digits has been exceeded.