Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 594

Compounding Turning Routines

Chapter 24

24-30

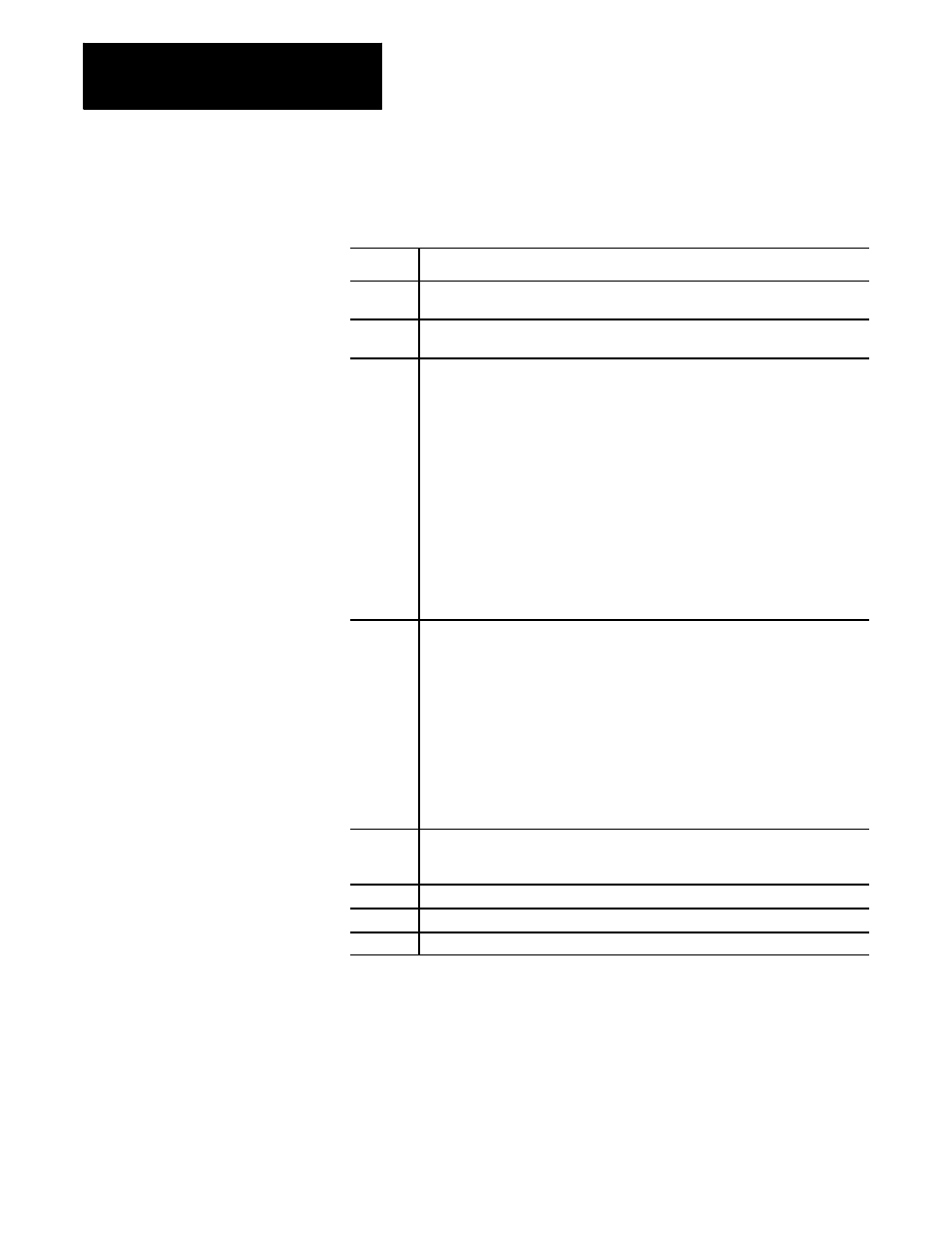

The G75 block is programmed with this format:

G75 P__ Q__ I__ K__ U__ W__ D__ F__ S__ T__;

Where :

Is :

P__

The sequence number of the first block in the set of contour blocks that defines the

finished workpiece shape.

Q__

The sequence number of the last block in the set of contour blocks that defines the

finished workpiece shape.

U W

Finish allowance. These parameters determine the finishing allowance that is left on

the part when the routine is completed. This finish allowance is typically removed

later in the program when a G72 finishing routine block is executed. The actual value

of the finish allowance is equal to the average of the U and W parameters ((U+W)/2).

It is not necessary to enter both of these parameters in the calling block. If only one

is entered, the control uses half of the entered parameter value as the finish amount.

The finish allowance is optional and does not need to be programmed. See

Figure 24.25 to determine the sign of U and W. U and W are always programmed as

incremental values.

Important:

This manual makes the assumption that W and U are assigned in

AMP as the incremental axis names that correspond to the Z and X axes

respectively.

Important:

The value assigned to U is affected by radius/diameter mode

(G08/G09). W is not affected by radius diameter mode. If programming in diameter

mode the value of the finish allowance is really ((U/2)+W)/2.

I K

These parameters determine the incremental distance between the first and last pass

of the routine. This distance is equal to the average of the I and K parameters

((I+K)/2). The location of the last pass is determined by the contour blocks and the

finish amount ((U+W)/2), if any is programmed. I and K must be programmed. They

are neither positive nor negative.

Important:

This total incremental distance should be less than one tool radius if

cutter compensation is on when this cycle is executed.

Important:

This manual makes the assumption that K and I are assigned in

AMP as the integrand axis names that correspond to the Z and X axes respectively.

Important:

The values assigned to I and K are always an incremental, radius

value regardless of the current mode (radius/diameter or absolute/incremental).

D__

Number of passes. The integer value entered with this parameter determines how

many passes are made to reach the final pass. The depth of each pass is

determined by dividing (I+K)/2 by D-1. The value entered with D must be an integer.

F__

Active feedrate during the routine only (see chapter 17)

S__

Spindle speed during the routine only (see chapter 16)

T__

Tool number and tool offset to be used during the routine only (see chapter 19)

Important: Any F-, S-, or T-words that are in the set of contour blocks are

ignored when the routine is executed. If these words are to be changed

from their current value, it is necessary to program an F-, S-, or T-word in

the G75 block. If programmed in the G75 block these words replace any

previously active modal F-, S-, or T-words for the remainder of G75

routine operation only. When the G75 routine is completed the previously

active modal F-, S-, and T-words are reactivated.