The format for this cycle is – Rockwell Automation 8520 9/Series CNC Lathe User Manual

Page 561

Grooving/Cutoff Cycles

Chapter 23

23-7

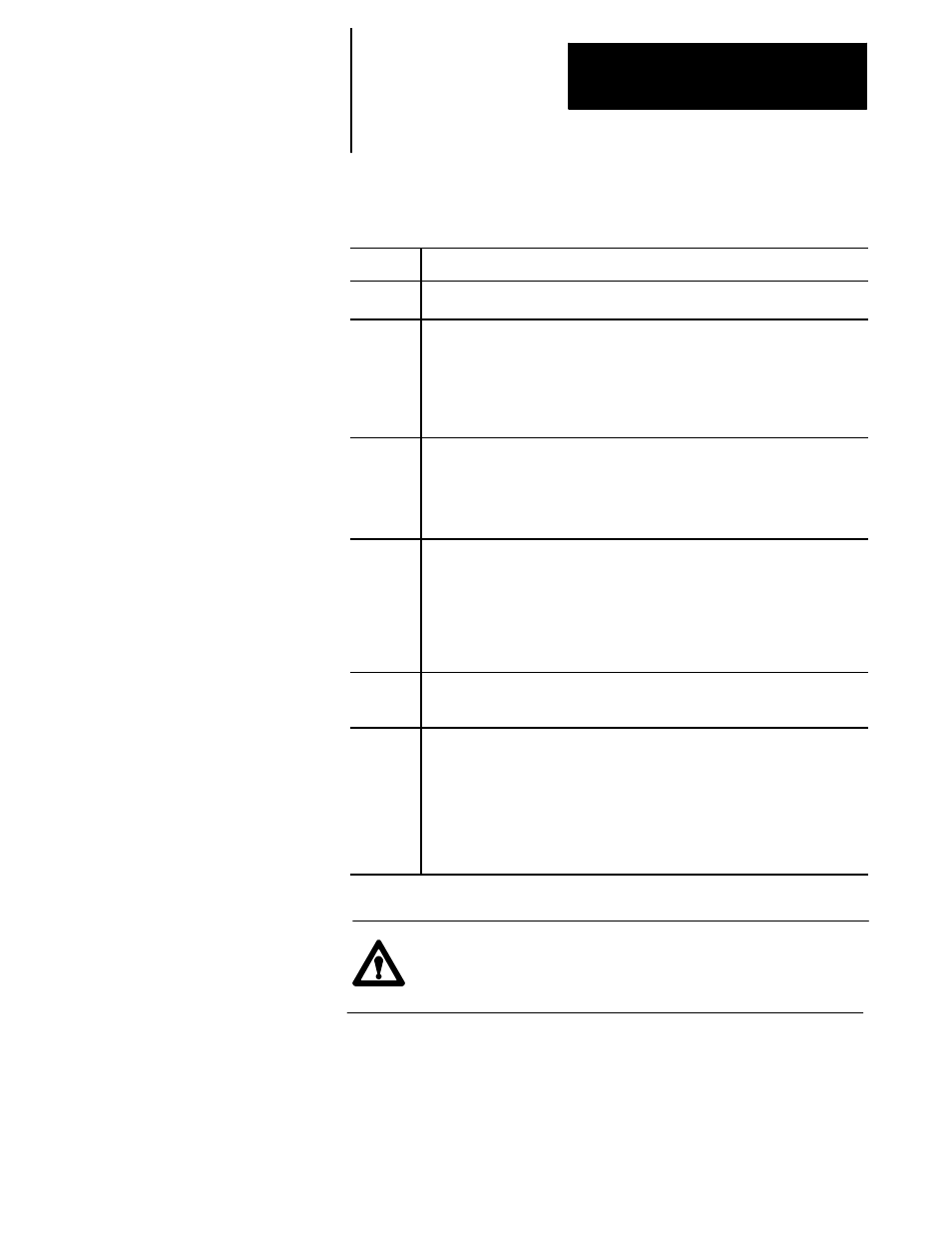

The format for this cycle is:

G77X__Z__I__K__F__D__;

Where :

Is :

Z__

the location where the last groove is cut. If only one groove is to be cut do not

program Z. This may be programmed as either an incremental or absolute value.

X__

the total depth of the groove from the X coordinate position of the tool prior to the

execution of the G77 block. If this cycle is to be used as a cut off cycle the depth

programmed here should drive the tool through the center or inside diameter of the

part. If a cut off is being made from the inside of the part, it should drive the tool

beyond the outside diameter of the part. This value represents the location of the

bottom of the groove cut. It may be programmed as either an incremental or

absolute value and is also affected by radius or diameter mode (G07 or G08).

K__

the distance between each groove. If the distance between the location of the last

groove (programmed with Z) and the next to the last groove is less than the value

programmed with K, then the K value is not used to determine the position of the

last groove. The last groove is always cut at the location programmed with Z. The

K parameter is always programmed as an incremental value regardless of the

current mode of the control.

I__

the amount that the cutting tool infeeds into the workpiece with each step. The step

is followed by a retract of amount e (set in AMP by the system installer). The

cutting tool then infeeds into the workpiece an amount I + e, retracts an amount e,

infeeds I + e, retracts e, etc. This repeats until the total programmed depth of the

groove X is reached. When this depth is reached the cutting tool stops infeeding

and either shifts an amount D (if programmed) or retracts to the starting coordinate

at rapid feedrate. The I-word is always programmed as an incremental value

regardless of the current mode of the control.

F

optional in the grooving block. If programmed the value entered with this parameter

replaces the currently active feedrate used when infeeding into the part. If F is not

programmed the currently active feedrate is used.

D__

the size of the incremental shift move made by the tool when the full depth of a cut

off has been reached. This parameter must be programmed even if its value is zero

when not using this cycle as a cutoff. A value other than zero is assigned to D only if

the grooving cycle is being used as a cut off cycle. It is always an incremental value

regardless of the current mode. The sign of the value programmed with the D

parameter determines the shift direction and should move the tool away from the

part. Programming this shift during a cutoff move helps to provide a good finish

since the cutting tool is not touching the part when it is retracted at the rapid

feedrate.

CAUTION: The shift programmed with a D parameter is

executed as a rapid move. Make sure that the cutting tool is

clear to shift at the end of the grooving cycle.